Sand production line is also called machine-made sand production line, artificial sand production line, or crushed sand production line. It is usually composed of a feeder, screening machine, jaw crusher, impact crusher/cone crusher, sand making machine, conveyor, sand washer, centralized electronic control, and other equipment. It is a set of equipment systems that processes natural rock or construction waste into sand that meets the standards for construction and engineering through crushing, screening, shaping, washing, and other processes. According to the different needs of each industry, these equipment can be freely replaced or specially customized to meet the different production requirements of enterprises.

Sand Production Line Process

The process flow of the sand making production line consists of several major links: raw material feeding, coarse crushing, medium crushing, sand making, screening and grading, sand washing, stone powder control, finished product storage and transportation, environmental protection and automation control.

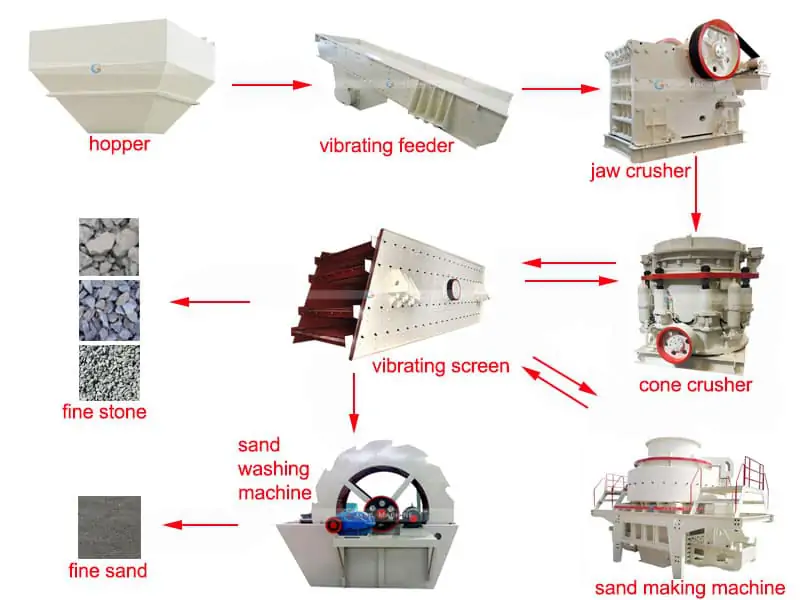

The raw sand and gravel enter the vibrating feeder, and the sand and gravel are transported to the jaw crusher for crushing through the elevator. After crushing, the raw materials are sent to the sand making machine through the conveyor, and then the sand making machine enters the vibrating screen for vibration screening and then enters the sand washing machine. After washing, the finished sand making machine sand is made to complete the sand making. Different processes can be selected according to the needs of different industries, and suitable equipment can be equipped to improve the storage and transportation of finished products and environmental protection needs, and increase our benefits.

Main Equipment Of Sand Production Line

The core equipment of sand production line includes crushing, sand making, screening, washing, conveying, dust removal and other categories;

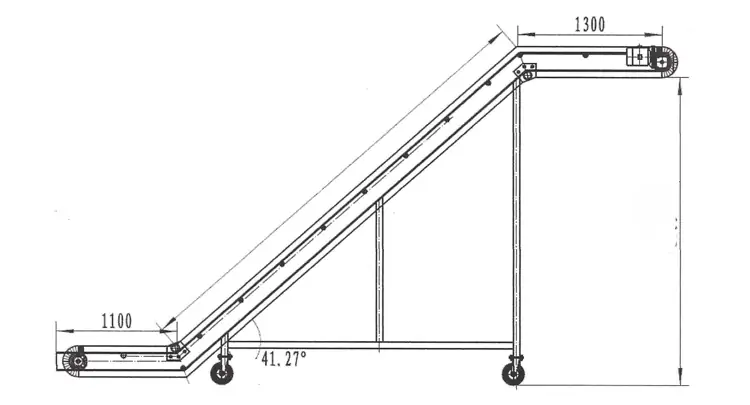

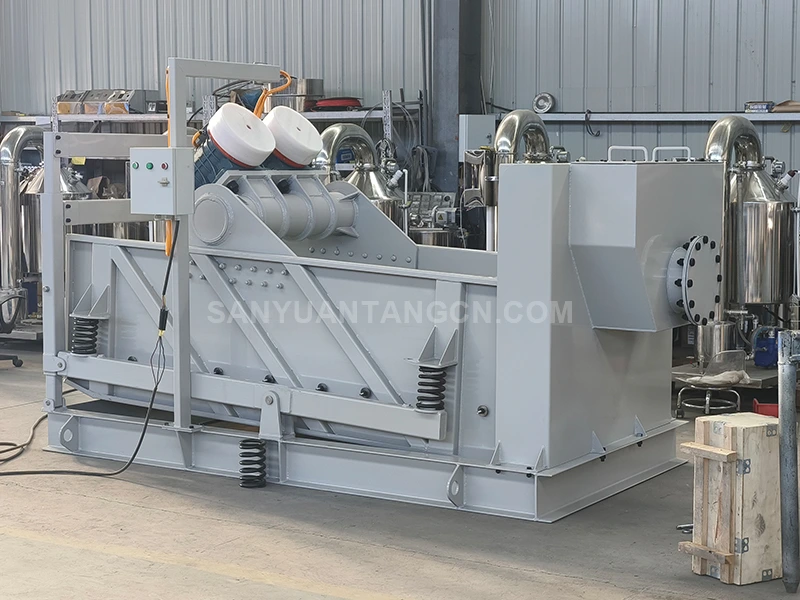

Classic equipment of sand production line includes crushing equipment: jaw crusher, cone crusher, impact crusher; sand making equipment: impact sand making machine, high-efficiency fine crusher; screening equipment: vibrating screen; washing equipment: bucket sand washing machine, spiral sand washing machine, fine sand recovery machine; conveying equipment: belt conveyor; auxiliary equipment: vibrating feeder, dust removal equipment, electronic control system, etc.

According to the different hardness and size of the stone, the sand production line should use appropriate crushing and sand making equipment in sand production to achieve the stability and efficiency of the sand production line.

Advantages Of Sand Production Line

The sand production line has high automation, low operating cost, high crushing rate, energy saving, large output, low pollution, and easy maintenance. The machine-made sand produced meets the national sand making standards, becoming one of the mainstream equipment production lines in the current sand making industry.

Improvement of production efficiency: The modern sand production line adopts integrated crushing and screening equipment, and cooperates with high-performance equipment. The processing capacity of a single machine can reach more than 500 tons/hour. The process is optimized to reduce energy consumption, while supporting continuous operation, greatly improving production efficiency, meeting the centralized sand supply needs of different projects, and reducing more production costs.

Control of finished sand quality: Multi-level crushing and perfect production technology make the finished sand grade accurately controllable, fully in line with GB/T 14684 standards.

Environmental protection: The fully enclosed production line is equipped with pulse dust removal and noise reduction modules to make dust emissions ≤20mg/m³ and noise less than 75 decibels. The water recycling system can achieve zero sewage discharge, and tailings can be made into recycled aggregates, with a resource utilization rate of over 95%.

Intelligence reduces operation and maintenance costs: The PLC central control system monitors the equipment status in real time, automatically adjusts parameters, and the fault warning accuracy rate exceeds 90%. It supports fast line change.

In general, the advantages of the sand production line are: sustainable resources, controllable quality, environmental compliance, high economic benefits and intelligent production.

With the depletion of natural sand resources and the tightening of environmental protection policies, machine-made sand has become the mainstream choice of the future construction industry, and the high efficiency, flexibility and environmental protection characteristics of the sand production line will be further popularized.

What Is The Price Of a Sand Production Line?

The price of a sand production line is affected by many factors, ranging from tens of thousands to millions of dollars (US dollars), depending on the production scale, equipment configuration, degree of automation and other factors.

Price Range of Sand Making Production Lines (USD Quotes)

| Production Line Scale | Capacity (t/h) | Equipment Configuration | Price Range (USD) | Application Scenarios |

| Small Scale | 20-50 | Jaw Crusher + Sand Maker + Simple Screening | 40K−110K | Individual Operators, Rural Sand Plants |

| Medium Scale | 50-200 | Jaw Crusher + Cone Crusher/Impact Crusher + Sand Maker + Vibrating Screen | 110K−420K | Small/Medium Quarries, Commercial Concrete Stations |

| Large Scale | 200-500 | Multi-Stage Crushing + High-Efficiency Screening + Sand Washing System | 420K−1.11M | Large Sand & Aggregate Bases |

| Extra-Large Scale | 500-1000+ | Fully Automated Line (Including Smart Control) | 1.11M−2.8M+ | State-Owned Enterprises / Global Mining Projects |

To obtain the detailed price of the sand making production line, you can contact us now and tell us your basic requirements (such as processing materials, output, finished product specifications, etc.). We will arrange experienced engineers to design a plan free of charge and provide you with a detailed quotation.

Conclusion

The sand production line processes rocks or construction waste into standard artificial sand and gravel through crushing, sand making, screening and other processes. The production line features a high degree of automation, low energy consumption, controllable quality of finished products, and flexible configuration to meet different production capacity requirements. The use of modern sand and gravel production lines can not only ensure the supply of sand and gravel but also achieve resource recycling, offering significant economic and environmental benefits. It is one of the main equipment lines in the future sand production industry. If you are also working in the sand-making industry and have any questions or equipment issues, you can contact us. With over 30 years of experience in manufacturing sand-making equipment, we look forward to cooperating with you.