The PVC belt conveyor is professional equipment designed for high-inclination material transportation, which can easily handle various bulk, block, and powder materials. Inductrial belt conveyor solves the limitations of traditional flat belt systems, can smoothly transport materials in steep or vertical directions, and provide more efficient and reliable solutions.

Belt Material: PVC/PU/Rubber or Customized

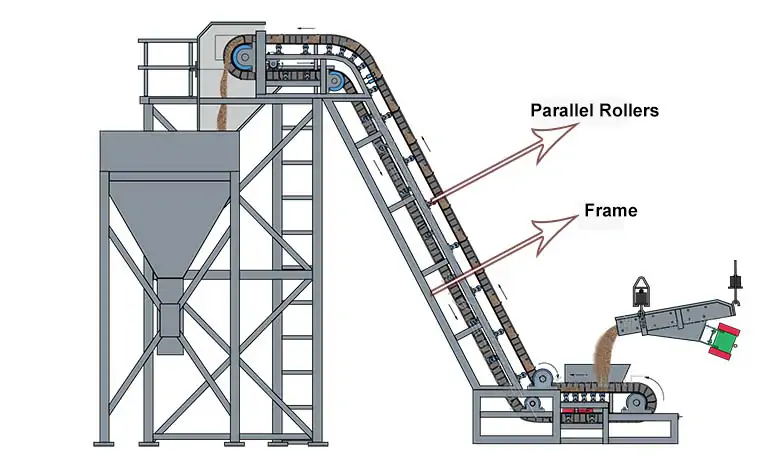

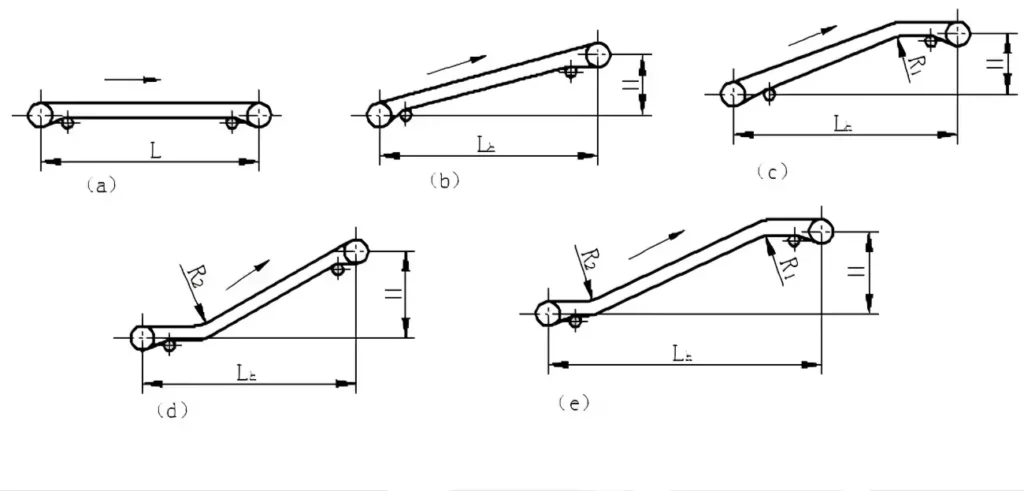

Conveyor Frame: The basic frame is shown in the figure below, and the hopper can be added

Weight Capacity(KG): 30-100 or Customized

Speed(m/min): 5-20 or Customized

Conveyor Height: Customized

Conveyor/Belt Width: Customized

Working principle

The working principle of a PVC belt conveyor system is divided into two stages: an ascending section and a horizontal section.

In the ascending section, the PVC conveyor belt moves upward with the material from the initial position. During the whole process, the conveyor belt is in a bent state. The belt conveyor quickly lifts the material to form a high-angle slope and then transfers it to the horizontal section.

The belt conveyor moves horizontally in the horizontal section to deliver the material to the destination. The belt conveyor at this stage is usually a carbon steel belt or a polyethylene belt, which has good load-bearing capacity and wear resistance.

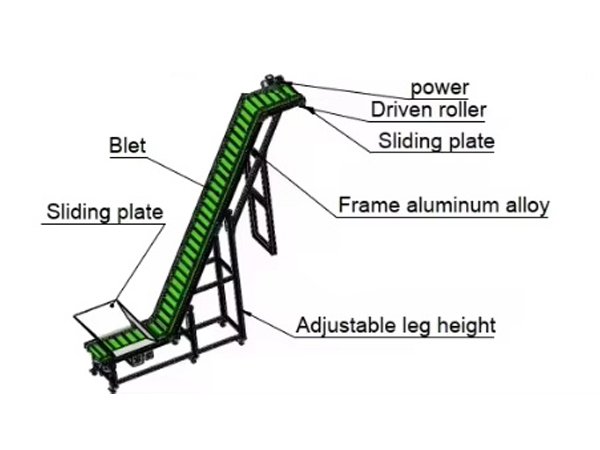

Structures:

A PVC green belt conveyor is a conveying equipment that can effectively solve the problem of large-angle conveying. It mainly comprises a conveyor belt, support roller, transmission device, support device, protection device, etc.

- Frame—-Export food hygiene SUS304 or carbon steel as you demand.

- Conveyor belt—-Food grade rubber, PVC, PU, or other material.

- Driving device—-electric motor or electric drum

- Belt speed—-Fixed speed or adjustable speed(frequency converter)

Electric Machine:

Electric Machine:

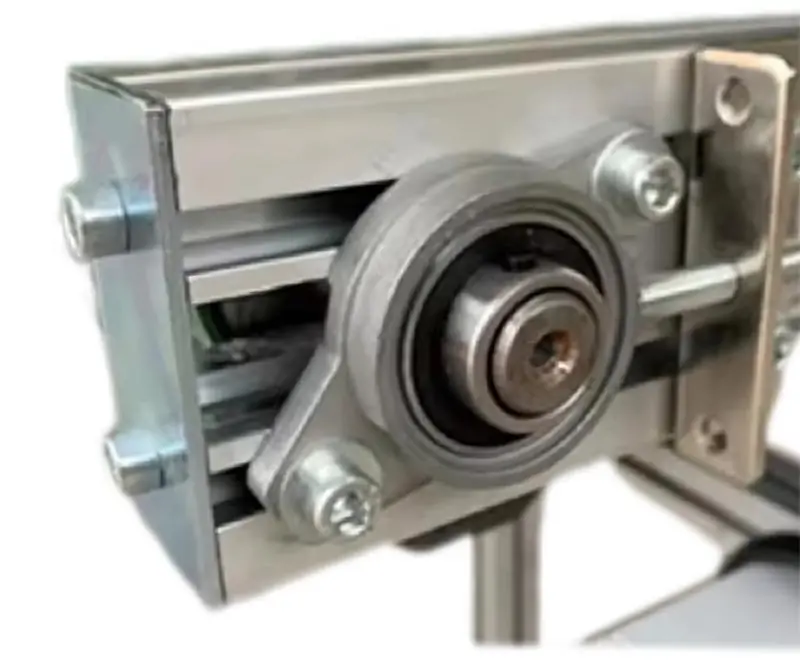

Select the high-quality motor and equip it with different power motors according to different loads, ensuring safety and reliability with a two-year warranty. Guide Rail Bracket Round Guide Rail:

Guide Rail Bracket Round Guide Rail:

Adjustable height and width to avoid dropping goods during the conveying Adjusting the Deviation Device:

Adjusting the Deviation Device:

Thickened aluminum block sur

face is Anodizing, fixed with stain

less steel full set of screws, solid

and durable without deformation

and left and right aluminum

blocks can be adjusted for devia

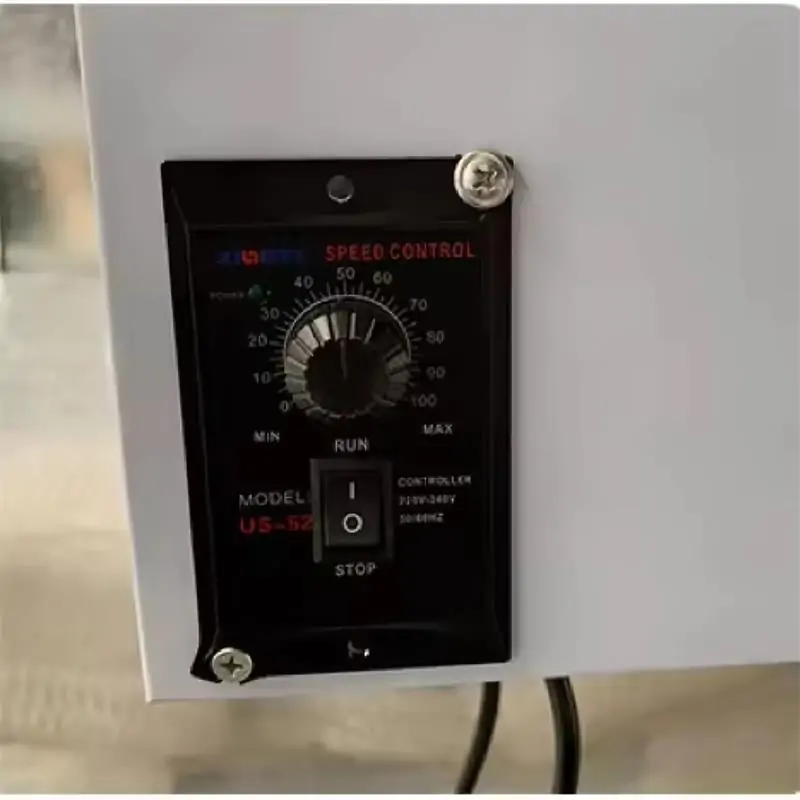

tion Speed Control:

Speed Control:

Adjustable express delivery, specific speed can be adjusted according to customer needs, reliable qualitv, durabilitv. low noise, high product stability, and quality assurance

Technical Parameters of PVC conveyor belt specification

| Belt width(mm) | 300 | 400 | 500 | 650 | 800 | ||||||||

| Sidewall height(mm) | 40 | 60 | 60 | 80 | 80 | 120 | 120 | 160 | 120 | 160 | 200 | 240 | |

| Conveying Capacity: Q3/h | 30° | 15 | 14 | 20 | 34 | 46 | 71 | 104 | 120 | 128 | 157 | 195 | 235 |

| 45° | 11 | 10 | 14 | 26 | 35 | 57 | 83 | 97 | 102 | 127 | 157 | 195 | |

| 60° | 8 | 7 | 10 | 18 | 25 | 40 | 58 | 69 | 72 | 90 | 112 | 142 | |

features of Inclined PVC belt conveyor

- The PVC belt conveyors can reach conveying angles of up to 90 degrees, reducing floor space.

- Enhanced material safety: To meet the challenges of steep conveying angles, the conveyor system uses a climbing conveyor belt. Side guards and transverse partitions can be added to prevent material from sliding backwards and spilling.

- Tailor-made specifications: PVC belt conveyors are available in a variety of main specifications, including 400mm, 500mm, 600mm and 800mm widths, and heights that can be customized to specific production requirements.

- Versatile loading and unloading: The conveyor system provides flexible loading and unloading capabilities. Feeding equipment is integrated at the bottom of the conveyor to achieve precise and uniform product delivery.

Application

- Mining and Quarrying: PVC belt conveyors are used to transport mined materials such as coal, ores, and aggregates from the excavation site to the processing plant or stockyard. The incline allows for efficient material movement over uneven terrain.

- Agriculture: These conveyors are used in agricultural settings for tasks like loading grain into storage silos or transferring harvested crops from one processing unit to another. They can also be utilized in greenhouses for moving soil or harvested produce.

- Manufacturing: In manufacturing facilities, inclined PVC belt conveyors are used for transporting raw materials, components, or finished products between different stages of production. They are particularly useful in assembly lines where items need to be elevated to different workstations.

- Food Processing: In the food industry, PVC/PU belt conveyors are employed for tasks such as transporting fruits, vegetables, grains, or packaged food items between processing stages. They can also be used for loading or unloading trucks in food distribution centers.

- Warehousing and Logistics: PVC belt conveyors are used in warehouses and distribution centers for tasks like loading and unloading trucks, moving goods to different levels of storage racks, or conveying items to packing stations for shipping.

- Construction: In the construction industry, inclined PVC belt conveyors are utilized for transporting materials like sand, gravel, or concrete mix to higher elevations, such as feeding materials into hoppers or mixers at construction sites.

- Waste Management: PVC belt conveyors are used in recycling facilities and waste management plants for transporting sorted recyclable materials or waste items to different processing units or storage areas.

- Automotive Industry: In automotive manufacturing plants, PVC belt conveyors are employed for moving car components or assemblies between different stages of production, such as from the stamping area to the assembly line.

- Power Plants: In power generation facilities, industrial belt conveyors are used for transporting coal or biomass fuel from storage silos to the boiler feed systems for combustion.

- Ports and Terminals: In maritime settings, PVC belt conveyors are used in port facilities for loading and unloading bulk cargo such as coal, grain, or ore from ships to storage facilities or vice versa.

PVC conveyor belt supplier

Sanyuantang is a high-quality PVC conveyor belt supplier and factory, provides durable and efficient conveying solutions for various industries. Our PVC conveyor belts have good wear resistance, chemical resistance, and extreme temperature resistance. Whether you need a conveyor belt for the food, medical or chemical industry, we can provide tailor-made solutions to meet your specific requirements.

More About Belt Conveyor

- Difference Between Belt Conveyor And Chain Conveyor

- Understanding the Inclination Angle of Belt Conveyors

- Sand Conveyor Belt Types And Price

- The Role Of Sand Conveyor Belt In Sand Making Plant

- Inclined Conveyor Belt Fasteners: Selecting, Trimming, And Installing

- What Is Sand Gravel Aggregate Production Equipment?