When using an incline conveyor belt, the right fasteners can ensure the stability, safety, and longevity of the conveyor belt. The following are key points about the selection, squaring, and installation of incline conveyor belt fasteners:

How to Choose Inclined Conveyor Belt Fasteners?

Table of Contents

Fasteners play a vital role in belt conveyor systems. To choose suitable belt conveyor fasteners, you must first understand the type and purpose of the conveyor belt and consider the type and environment of the belt conveyor. Because different types of conveyor belts may require different fasteners.

1. Selection of fastener materials

| Corrosion-resistant But Low Strength | Characteristic | Applicable Environment |

|---|---|---|

| Steel fasteners | High strength and durability | Most general environments |

| Stainless steel fasteners | High temperature and corrosion resistance | Wet or corrosive environment |

| Plastic fasteners | Corrosion-resistant and light weight | Light load or non-industrial environment |

| Aluminum alloy fasteners | Corrosion-resistant and lightweight | Light load conveying environment |

2. Fastener trimming

With the long-term use of the conveyor belt, the fasteners may become loose, worn, or damaged, so it is very important to regularly check and trim the fasteners. The trimming work includes:

- Check for looseness: Regularly check whether the fasteners are loose, and ensure that the fasteners are firmly fixed to the conveyor belt to prevent falling off or damage caused by looseness.

- Wear inspection: Long-term operation will cause fasteners to wear, especially in high-load and high-speed environments. Check the degree of wear of the fasteners and replace the severely worn parts in time to avoid affecting the normal operation of the conveyor belt.

- Adjust the tension: The fasteners need to maintain appropriate tension after installation. If the tension is insufficient, it may cause the conveyor belt to slip or deflect. Adjust the fasteners in time to keep the tension of the conveyor belt stable.

3. Fastener installation

Proper installation can not only increase the service life of the inclined conveyor belt but also avoid problems during operation. The following steps need to be followed when installing fasteners:

- Clean the working surface: Before installing the fastener, make sure that the contact surface of the conveyor belt is clean and free of dust, oil, or debris. A clean installation surface helps the fastener to have good contact with the inclined conveyor belt and avoid sliding or loosening.

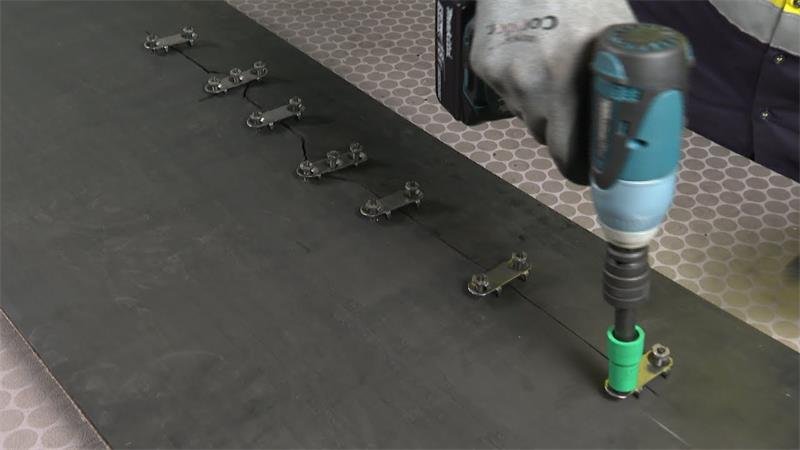

- Choose the right tool: Use the right tool for installation to avoid damage to the fastener or loose installation due to improper tools.

- Uniform installation: The fasteners should be installed evenly to ensure that the connection of the entire inclined conveyor belt is tight and uniform. If multiple fasteners are used, ensure that their spacing is consistent to avoid unbalanced loads due to uneven spacing.

- Check alignment: During installation, ensure that the fasteners are correctly aligned with the running direction of the conveyor belt to avoid affecting the working effect of the conveyor belt due to installation deviation.

4. Convenient installation and maintenance

- Regularly check and tighten the fasteners to avoid deviation or damage to the conveyor belt due to looseness or wear.

- Prevent excessive tension. Overtightened fasteners will cause excessive pressure on the conveyor belt and the fasteners themselves, reducing their service life.

- Replace damaged fasteners. If you find that the fasteners are damaged or severely worn, they should be replaced in time to ensure the normal operation of the conveyor belt.

- By properly selecting, trimming and installing fasteners, the stability, efficiency and service life of the inclined conveyor belt can be greatly improved.

How to make the Inclined conveyor belt straight?

In the conveying system, the centering and tensioning of the belt conveyors are key factors to ensure the long-term and efficient operation of the equipment. Therefore, how to keep the conveyor belt parallel is an important step in maintaining and managing the conveyor belt system.

1. How to check whether the conveyor belt is parallel?

- Visual inspection: Check from the side or above whether the conveyor belt is parallel to the roller or drive wheel to see if it is obviously tilted or asymmetrical.

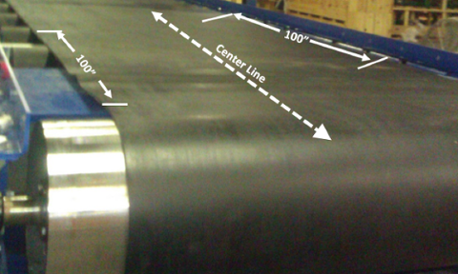

- Check with measuring tools: Use a tape measure or laser centering tool to measure whether the distance between the conveyor belt and the equipment frame or conveyor shaft is uniform.

- Check when the equipment is running: Start the conveyor belt and observe whether the belt speed is stable, whether the material flow is uniform, and whether there is any deviation.

2. How to adjust the conveyor belt to make it parallel?

Adjust the conveyor belt tension

The non-parallelism of the conveyor belt may be caused by uneven tension, so the tension on both sides can be balanced by adjusting the tensioning device. Measuring the distance between your marks while tensioning the belt will give you the tension percentage. For example, if the belt stretches to 100.5 inches, this indicates a 0.5% tension. For the optimal tension setting, refer to the recommendations provided by your belting supplier.

Adjust the guide device

By adjusting the guide device, the conveyor belt can be helped to run along the correct track and reduce the risk of deviation.

Adjust the rollers and support structures

The centering accuracy of the rollers or support structures will affect the deviation of the conveyor belt. Therefore, please ensure that all rollers and support bearings are parallel to the center line of the conveyor belt to keep the conveyor belt running smoothly.

Regular inspection and maintenance

Regular inspection and maintenance can repair worn conveyor belts and components in time, prevent the occurrence of non-parallelism, and thus avoid large-scale failures.

Sanyuantang: Your reliable Belt Conveyor fastener supply partner

In summary, choosing the right fasteners is crucial to the stability and safety of equipment. As a leading fastener supplier in the industry, Sanyuantang is committed to providing high-quality, durable fastener solutions. Whether it is a conveyor belt system, mechanical equipment, or building structure, Sanyuantang’s rich product line and customized services can meet your various needs. If you have any questions about inclined conveyor belts, please feel free to contact our team.

Related Articles

- Sand Conveyor Belt Types And Price

- Understanding The Inclination Angle Of Belt Conveyors

- The Role Of Sand Conveyor Belt In Sand Making Plant

- Chain Conveyor VS Belt Conveyor

- How To Prevent Dust In Sand Making Production Line

- How To Minimize Spillage In The Conveyor Belt

- Noise Consideration Of Belt Conveyor

- The Most Commonly Used Mobile Conveyor Belt