The sand and gravel conveyor belt is a conveying system specially designed for efficiently conveying loose materials such as sand and gravel. It is usually used in conjunction with vibrating feeders, crushers, vibrating sand screening machines, and other sand making equipment to form a complete gravel production line, realizing the automation and intelligence of gravel production.

Belt width: 400-1000mm

Conveying capacity: 70-300m³/h

Conveying length: 10-15 meters

Conveying speed: 1.25-2.0 m/s

Belt Material: Polyester, Cotton, Nylon, Steel Cord.

Application: Quartz sand, fracturing sand, pebbles, river pebbles, limestone, marble, basalt, limestone, calcium carbonate, and other sand and gravel plant machine-made sand production lines.

Working Principle

The sand and gravel conveyor belt system is an efficient and continuous material conveying equipment. Its working principle is based on the friction between the belt and the transmission drum and the supporting role of the roller. During operation, the motor drives the transmission drum to rotate, and the drum drives the belt and the gravel material on it to move together through the friction between the belt and the belt. The belt supported and guided by rollers, forms a continuous conveying path to transport materials from one end to the other. During the conveying process, the material maintains a stable state of motion until it reaches the unloading device, which unloads the material from the belt. The unloading device can be a roller unloading, a scraper unloading or a special unloading device, which can be selected according to actual needs.

Structures

The main structure of the sand conveyor belt:

- Drive roller: The motor drives the belt to move.

- Belt: As the material bearing and traction component, it has high strength and good wear resistance.

- Roller: Installed on the frame, used to support the belt and the material on the belt to prevent the material from falling or accumulating.

- Drive device: includes motor, reducer, brake, etc., to provide power for the drive roller.

- Discharging device: At the end or specific position of the belt conveyor, it is used to unload materials.

Specifications

| Belt width (mm) | Conveying length(m) Power(kw) | Conveying speed (m/s) | Conveying amount (t/h) | ||

| B400 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 30-60 |

| 3 | 3-4 | 4-7.5 | |||

| B500 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 40-80 |

| 3 | 4-5.5 | 5.5-7.5 | |||

| B650 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 80-120 |

| 4 | 7.5 | 7.5-11 | |||

| B800 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 120-200 |

| 4 | 7.5 | 7.5-15 | |||

| B1000 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 200-320 |

| 5.5 | 7.5-11 | 11-22 | |||

| B1200 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 290-480 |

| 7.5 | 7.5-15 | 15-30 | |||

| B1400 | ≤10 | 10-20 | <20-40 | 1.25-2.0 | 400-680 |

| 11 | >15-22 | 22-45 | |||

Different types of sand gravel conveyor belts

Sand and gravel conveyor belts can be divided into the following types according to the conveying angle and function:

Classification from different conveying angles:

The angle classification of gravel belt conveyors is mainly based on design purpose, load type, and conveying efficiency. The following two are commonly used angles for gravel belt conveyors:

Classification from different functions

In the sand making production line, there are usually two most commonly used gravel conveyor belts, such as fixed belt conveyors and mobile gravel belt conveyors. The specific differences are as follows:

Horizontal Sand conveyor belt

The inclination is usually below 15 degrees, suitable for horizontal gravel transportation in mines, construction sites, and other places.

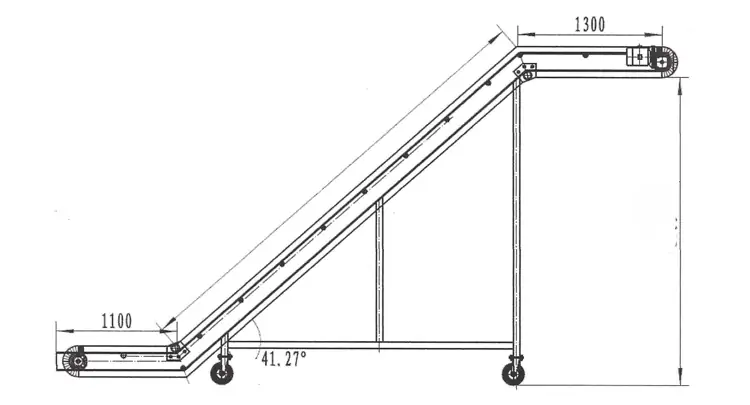

Inclined Sand conveyor belt

The inclination of inclined conveyor belt is usually between 15 and 90 degrees, suitable for places that need to cross height differences, such as gravel transportation from the ground to the material yard.

Fixed belt conveyor

Installed in a fixed position, cannot be moved, performs long-term or permanent conveying tasks, is suitable for fixed production lines or sites, and has a fixed conveying direction and position.

Mobile gravel belt conveyor

It can be moved and arranged as needed, suitable for occasions where the conveying position needs to be changed frequently or for temporary projects.

Application

The sand conveyor belt has the advantages of simple structure, stable operation, high conveying efficiency, and strong adaptability. It is widely used in industrial fields such as sand and gravel plants, providing efficient and reliable solutions for material transportation in underground tunnels, surface transportation systems, open-pit mines, and ore dressing plants.

Custom Sand conveyor belt

- Belt width and length: Customized to the required material flow and transport distance.

- Incline/decline angle: Adjusted to site layout and material handling requirements.

- Belt material and design: Wear-resistant cleats, sidewalls or V-shaped patterns to prevent material spillage, etc.

- Loading and unloading mechanisms: Include hoppers, chutes or gates to facilitate loading and unloading of sand and gravel.

- Conveyor speed and control: Variable speed drives or control systems can be used to accurately control conveyor speed, efficient processing and minimize spillage.

- Additional features: Covers or enclosures can be installed to control dust or prevent material contamination. Buffer beds, skirt systems or seals can be added, etc.

Get a Quote

Sand making equipment production system

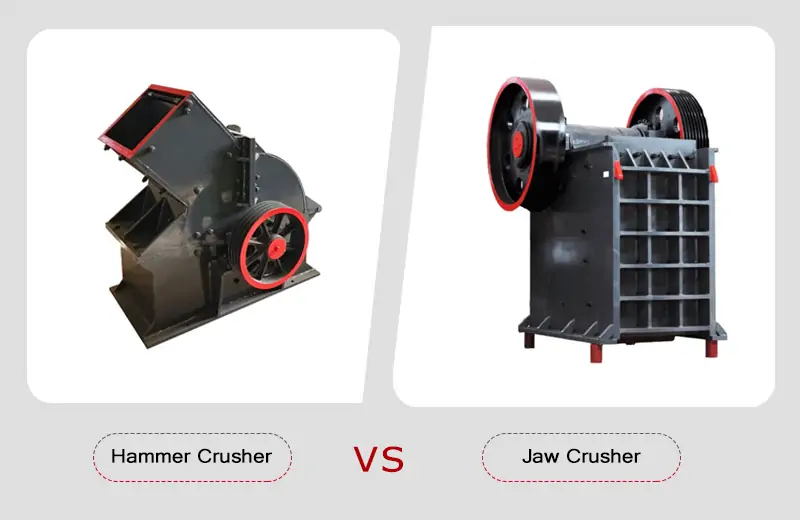

Sand and gravel conveyor belt usually forms a complete sand-making production line with sand making equipment. The system equipment mainly includes vibrating feeder, crushing equipment, sand washer, belt conveyor, bucket elevator, sand screening machine, etc. The sand conveyor system can be customized according to the actual production needs of the sand and gravel plant. It can be transported by a single unit, or it can be composed of multiple units or with other conveying equipment to form a horizontal or inclined conveying system to meet the needs of different layout forms of operation lines.

sand and gravel conveyor belt manufacturer

Sanyuantang is a large-scale sand and gravel production line belt conveyor manufacturer. We provide sand and gravel belt conveyor systems, sand production line system design, and equipment manufacturing for sand and gravel plants of various sizes. It is widely used in mining production lines, sand and gravel plant production lines, construction waste treatment production lines, etc. It can meet the needs of various production scales of machine-made sand production lines.