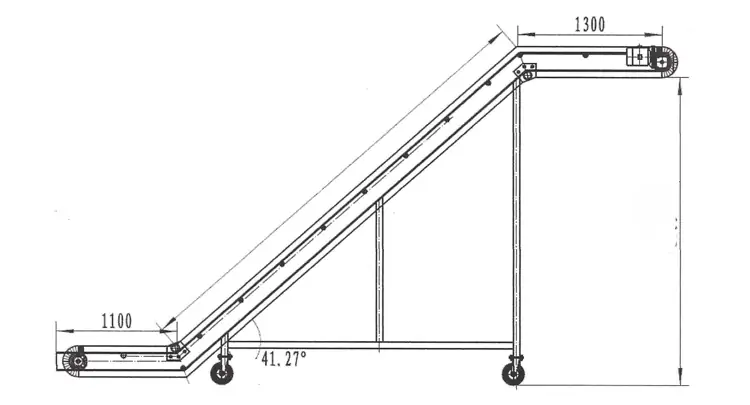

Belt conveyors are a widely used material handling system. Inclination refers to the tilt of the conveyor belt relative to the horizontal plane and plays a key role in determining material conveying efficiency and capacity. Typically, the inclination ranges from 0° to 90°. When setting the inclination, it is important to consider factors such as the characteristics of the material, the conveying distance and the flow rate.

Different inclination angles of belt conveyors

15° inclination angle:

Slight inclination, suitable for handling materials with good fluidity, widely used in coal mines, building materials, chemical industry and other industries, especially suitable for conveying granular or block materials.

30° inclination angle:

The angle is just right, which can balance the conveying efficiency and energy consumption. It is widely used in mining, ports, grain processing and other industries to convey coal, ore, grain and other materials.

45° inclination angle:

The angle is larger, suitable for handling materials with high viscosity. It is widely used in cement, chemical, metallurgy and other industries, and can effectively prevent the accumulation and blockage of powdery or granular materials.

75° inclination angle:

The steep inclination angle of 75° is designed for materials with fine particles and easy to scatter. It is widely used in mineral processing, construction waste treatment and other fields to improve the conveying height and conveying efficiency of such materials.

90° vertical conveying:

Vertical or nearly vertical material conveying, suitable for occasions where materials are conveyed from bottom to top. It is widely used in special fields such as garbage disposal and food processing.

Technical Parameters Of Inclined Belt Conveyor

| Belt width(mm) | 300 | 400 | 500 | 650 | 800 | ||||||||

| Sidewall height(mm) | 40 | 60 | 60 | 80 | 80 | 120 | 120 | 160 | 120 | 160 | 200 | 240 | |

| Conveying Capacity: Q3/h | 30° | 15 | 14 | 20 | 34 | 46 | 71 | 104 | 120 | 128 | 157 | 195 | 235 |

| 45° | 11 | 10 | 14 | 26 | 35 | 57 | 83 | 97 | 102 | 127 | 157 | 195 | |

| 60° | 8 | 7 | 10 | 18 | 25 | 40 | 58 | 69 | 72 | 90 | 112 | 142 | |

Features of belt conveyors with increased conveying angles

- Large-angle conveying: Up to 90° material conveying can be achieved, effectively shortening the conveyor length and reducing construction costs.

- Enclosed conveying: No additional conveying corridor or sealing cover is required, and two conveyor belts are clamped to achieve closed material conveying to prevent leakage.

- Efficient and stable: large conveying volume, stable operation, and meet various material conveying needs.

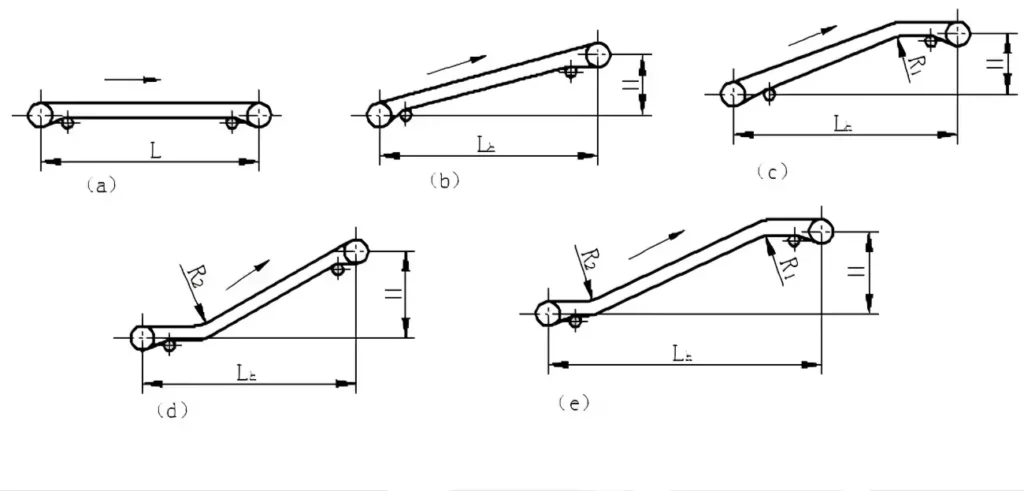

Analysis of inclination angles of different types of belt conveyors

Flat belt and large-angle belt conveyors:

Flat belt conveyors are good at long-distance, large-capacity, and long-term conveying, and their conveying inclination angle generally does not exceed 28°. In contrast, large-angle belt conveyors can work efficiently in the range of 30° to 90° and are designed for high-angle conveying.

Pattern belt and deep groove (round tube) belt conveyors:

Pattern belt conveyors increase the friction coefficient by increasing the pattern on the surface of the conveyor belt to achieve large-angle conveying. The deep trough belt conveyor uses a U-shaped or circular tube structure to support the conveyor belt. Compared with ordinary belt conveyors, it has stronger material restraint ability and is suitable for large-angle conveying.

Structural advantages of large-angle belt conveyors:

Large-angle belt conveyors not only increase the conveying height, but also effectively increase the friction between the conveyor belt and the material by adopting a wavy edge belt design, reduce the self-flow of materials, and improve the conveying efficiency.

Conclusion

The belt conveyors produced by our manufacturer have various conveying angles to choose from, which can meet the conveying needs of different industries and different material characteristics. If you have more questions or needs about the inclination angle or other aspects of the belt conveyor, please feel free to contact us, we will provide you with professional answers and customized solutions.