Grain belt conveyor is one of the main equipment used in agriculture for transporting grain and other bulk materials. It consists of a belt made of rubber or fabric, which is rotated by the drive of two or more pulleys, thus conveying grain from one position to another. This kind of conveyor is widely used in grain elevation, grain storage, agricultural processing plants, etc. It is capable of handling a wide range of grains such as wheat, corn, rice, soybean, barley, etc.

Application of Grain Belt Conveyor

Grain belt conveyor is widely used in agriculture, from grain storage to processing, loading and unloading, transfer and other aspects have its figure.

The following are the main application scenarios of grain belt conveyor:

Storage of grain: In storage of grain silos, silos, etc., grain belt conveyor is used to transport grain from the unloading area to the storage location. Its continuous and smooth working enables efficient transfer and storage of grain.

Processing of grain: In processing sites such as flour mills, feed mills, ethanol production plants, etc., the grain belt conveyor fulfils the task of transferring grain between the different processing stages. For example, conveying grain from cleaning equipment to mills and transporting it to mixing equipment or packaging lines, enabling a fully automated flow in the production process.

Loading and unloading of grain: In silos, ports and terminals, grain belt conveyors are commonly used for loading and unloading grain from trucks, trains or ships. It enables the rapid transfer of grain from the conveyor to the storage facility. It is also possible to transfer substances such as grain from storage facilities to means of transport.

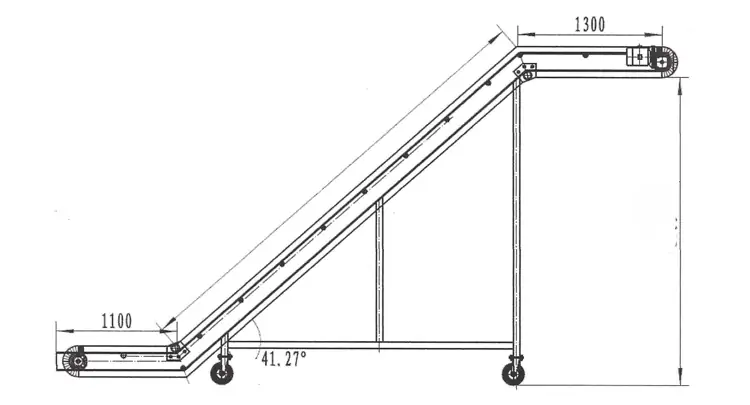

Grain transfer and distribution: the grain belt conveyor is capable of operating horizontally, vertically or at an incline, adapting to the needs of different terrains and facility layouts. It can easily transfer grain from one place to another, and transfer at height is not a problem. It allows for more flexible distribution of grain during processing or storage.

Biofuel production: In addition to grain, this conveyor can also be used to transport agricultural residues such as corn stover and wheat straw to biofuel production facilities to support the production of bioenergy.

Distribution of grain: In the distribution of grain, grain belt conveyors transport grain from production facilities to distribution centres, grain terminals or export facilities, enabling timely and efficient delivery of grain to consumers or to international markets.

Working Principle of Grain Belt Conveyor

The working process of a grain belt conveyor can be divided into the following steps:

Loading : Grain is loaded onto the conveyor belt by means of a hopper, chute or other equipment (e.g. bucket elevator, screw conveyor). The loading method can be flexibly adjusted according to the actual demand, so that the grain can be evenly distributed on the belt.

Belt transmission: The motor drives the belt pulley (called drive pulley) to rotate and drive the belt to move continuously. The running speed of the belt can be adjusted according to the need to adapt to different conveying requirements.

Grain conveying: When the belt moves, the grain is conveyed forward together with the belt. The surface of the belt is usually designed with non-slip texture or retaining edges to prevent the grain from slipping or rolling off during transport.

Unloading: Once the material reaches its destination, the grain is unloaded from the belt through a discharge opening, chute or other device. The unloading methods are various, it can be directly unloaded into the storage bin or transferred to other conveying system or processing equipment to meet the needs of different scenarios.

Conclusion

Grain Belt Conveyor has become an indispensable equipment in modern agricultural production and grain handling with its wide range of applications, work volume engaged, and flexible application. It can not only greatly improve the transport efficiency of grain, but also adapt to a variety of complex working environments, to meet the needs of each link from storage to processing, loading and unloading, transshipment and so on. In addition, its simple structure and easy maintenance also reduce the cost of use, further enhancing its market competitiveness. It provides an efficient and reliable solution for grain production, storage, processing and logistics.