Double deck vibrating screen is one of the common and efficient screening equipments, which adopts double deck screen mesh and three outlets structure, and can accurately classify the materials into coarse, medium and fine three different particle sizes at one time. Its screening efficiency is up to 96%, which is widely used in chemical, food, building materials and other industries.

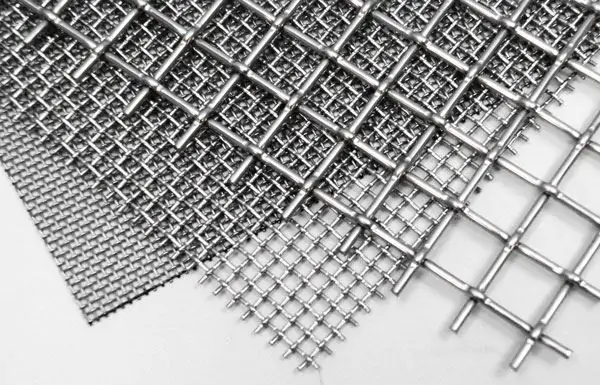

We can also customise the production of multi-layer screen mesh and multiple outlets combined vibrating screen to meet the production needs of enterprises. The upper screen mesh first intercepts large particles, the middle screen mesh separates medium size materials, and the finest particles fall into the fine material outlet through the bottom screen mesh. This article will analyse its working principle and application scenarios in detail.

The screening principle of double deck vibrating screen

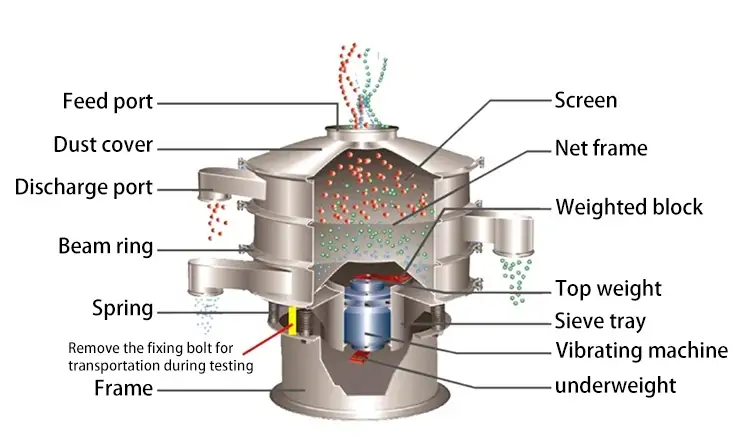

Double deck vibrating screen mainly relies on the excitation force generated by the vibrating motor to drive. When the material is evenly put into the screen surface from the inlet, driven by the vibrating motor, the screen box starts to make regular circular motion. This movement makes the material present spiral diffusion state on the screen surface, from the centre area gradually to the surrounding uniform distribution.

In the working process of double deck vibrating screen, the material is first contacted by the upper layer of the screen. Due to the vibration effect, particles smaller than the aperture of the upper screen mesh quickly through the screen, falling into the middle layer of the screen surface; and larger than the size of the sieve hole of the material along the screen surface to continue to move forward, and ultimately discharged from the outlet of the coarse material. The middle screen surface with the same principle of the material for the second screening, medium size of the material from the middle discharge port discharge, the finest particles through the lower screen mesh, from the fine material outlet collection.

Its entire screening process is a continuous work mode of operation, the equipment is equipped with vibration damping spring system can not only effectively reduce the working noise, but also extend the service life of the screen mesh. We have been doing vibrating screening industry for 30+ years, served many enterprises in the screening industry, and got the unanimous praise, if you also have screening problems, you can contact us now, we will provide you with a reasonable and efficient screening programme.

Application

Double deck vibrating screen is widely used in food, chemical, pharmaceutical, metallurgy, building materials and other industries, especially suitable for fine screening of dry powder, fine powder and granular materials, such as abrasive raw materials, plastic granules, resin powder, ceramic powder, grain, fertiliser and so on. Its classification capacity can meet the strict requirements of different industries on the particle size of materials, and it is also one of the main screening equipment in the modern production line.

Related Articles

Related Equipment

In addition to the tea sifting machine, if you need other types of processing equipment, Sanyuantang Machinery can also provide reliable solutions, such as: