As a leading linear vibrating screen manufacturer, Sanyuantang specializes in delivering highly customized screening solutions designed to fit different materials, industries, and production environments. With more than 30 years of manufacturing experience, we provide professional customization services to ensure our linear vibrating screens meet diverse processing needs with maximum efficiency and reliability.

Below is a complete overview of our customization capabilities.

Table of Contents

Customized material

The material of the linear vibrating screen can be fully customised to match your production environment and material characteristics.

Available options include:

- Carbon steel — economic and durable

- 304 stainless steel — food-grade, corrosion-resistant

- 316L stainless steel — ideal for corrosive or high-purity applications

Choosing the correct material ensures stable operation, longer service life, and compliance with food or chemical industry standards.

Stainless Steel Linear Vibrating Screen

Stainless Steel Linear Vibrating Screen Carbon Steel Linear Vibrating Screen

Carbon Steel Linear Vibrating Screen

Customized size

All dimensions—including length, width, height, and screen deck layers—can be tailored to your plant layout and output requirements.

Our design team focuses on:

- Screening efficiency

- Capacity requirements

- On-site space limitations

- Integration with existing equipment

This ensures the screen fits seamlessly into your production line.

Large Linear Vibrating Screen Size

Large Linear Vibrating Screen Size Large Linear Vibrating Screen Size

Large Linear Vibrating Screen Size Mini Linear Vibrating Screen

Mini Linear Vibrating Screen Mini Linear Vibrating Screen

Mini Linear Vibrating Screen

Customised feed port

We offer multiple feed port shapes and structures:

- Rectangular feed port

- Circular feed port

- Flange-type feed port

Customised feed port design helps ensure smooth material flow and perfect connection with upstream conveyors, feeders, or production systems.

Square feeding port

Square feeding port Circular feeding port

Circular feeding port Closed feed port

Closed feed port

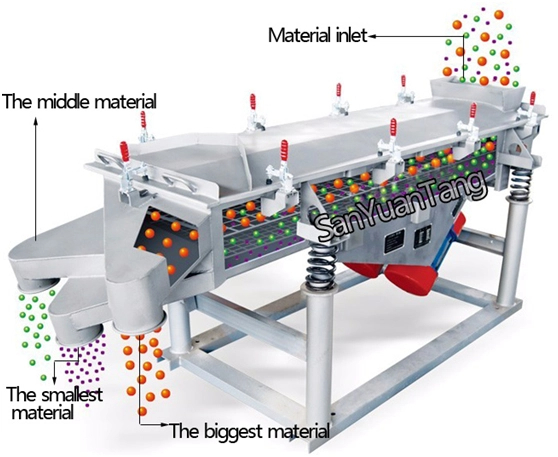

Customised discharge ports

The discharge ports can be designed based on:

- Material characteristics

- Required particle separation

- Connection methods with downstream equipment

We support single-discharge, multi-discharge, and special-angle discharge port designs to suit various screening processes.

Customized discharge ports

Customized discharge ports Customized discharge ports

Customized discharge ports Customized discharge ports

Customized discharge ports

Select Linear Vibrating Screen Motors

We provide a variety of customised sieve options, including coarse wire screens, fine wire screens, steel plate cut-hole screens, and strip screens. Customers can choose the most suitable screen type according to the particle size and characteristics of the screened material to achieve the best screening effect.

Metal Woven Mesh

Metal Woven Mesh Grid

Grid Punching plate

Punching plate

Customized motor position

The motor position of the linear vibrating screen can be customised to meet customer needs, with three options: top, bottom, or side. The installation position of the motor is usually related to the height and installation environment of the equipment. Customers can choose the motor installation position according to the limitations of the on-site space.

Downward vibration type

Downward vibration type Side vibration type

Side vibration type Up vibration type

Up vibration type

Select Linear Vibrating Screen Motors

Depending on your working environment, you may choose:

- Standard vibration motors

- Explosion-proof vibration motors (recommended for dusty or hazardous environments)

Explosion-proof motors effectively prevent dust explosion risks and enhance operational safety.

Special Customised Linear Vibrating Screen

Special customised linear vibrating screens are personalised designs for customers under specific working environments and production requirements. Compared with standard models, special customised linear vibrating screens can be customised according to actual conditions. For example, for places with special requirements such as dust prevention, cleaning or explosion-proof, we can provide customers with customised solutions with spray devices, dust removal systems or explosion-proof motors.

Customized spray device

For some materials that need to be cleaned or dusted, our company can customise a spray device for the linear vibrating screen. The device can lightly clean the material during the screening process to remove dust, while preventing the material from generating too much dust during the screening process.

dust removal device

In order to meet customers’ requirements for environmental hygiene, we can customise a dust removal system for the linear vibrating screen. The system includes a high-power exhaust fan installed above the equipment, and customers can adjust the position of the air duct according to the on-site conditions to achieve efficient dust removal.

Linear Vibrating Screen with Dust Removal Device

Linear Vibrating Screen with Dust Removal Device Linear Vibrating Screen with Dust Removal Device

Linear Vibrating Screen with Dust Removal Device

add wheels

In order to facilitate the movement of the equipment, we designed movable wheels for the linear vibrating screen. The wheels are equipped with a locking device, which can ensure the stability of the equipment during work and can be easily unlocked when it needs to be moved, making it easy to move and adjust the position.

Customized color

We can also customize the color of the equipment according to the customer’s corporate image or other requirements to meet different aesthetic and brand needs.

Blue

Blue Off-white

Off-white Grey

Grey

Sanyuantang is a professional linear vibrating screen manufacturer in China. We have 30 years of production experience and provide a variety of linear vibrating screen customization options to meet the special needs of different customers. In addition, we can also provide customers with complete screening, conveying and crushing solutions to ensure the efficient and stable operation of various sand and gravel aggregate production lines.

Why Choose Sanyuantang?

Sanyuantang is one of China’s most experienced linear vibrating screen manufacturers, offering:

- 30 years of industry expertise

- Complete customization capabilities

- Full screening, conveying, and crushing solutions

- Support for sand, gravel, mining, chemical, food, pharmaceutical, and new energy industries

We help customers build efficient, stable, and high-quality production lines with reliable screening equipment.

Related Articles

- Use And Maintenance Of Linear Vibrating Screen

- Linear Vibrating Screen VS Circular Motion Vibrating Screen

- How To Choose Linear Vibrating Screen Motor?

- How To Choose Screen Mesh Frame Of Linear Vibrating Screen

- Differences Between Probability Screen And Linear Vibrating Screen

- Differences Between Linear Vibrating Screen And Rotary Vibrating Screen

- Linear Vibrating Screen For Ceramic Sand Sieving