Introduction

The linear vibrating screen is essential equipment in various industries, from mining to food processing, ensuring materials are efficiently and accurately sorted. Proper use and maintenance enhance their performance and extend their lifespan. This article will help you learn how to use and maintain linear vibrating screens.

Linear Vibrating Screen Maintenance and Use

1. Electrical Protection Device

Equip the linear vibrating screen with an appropriate electrical protection device to safeguard the machine from potential electrical issues.

2. Anchor Bolts Inspection

During the initial phase of operation, it is crucial to inspect the anchor bolts at least once a day. This practice helps in preventing the bolts from loosening, which could affect the machine’s performance and safety.

3. Motor Rotation Direction

Ensure the motor’s rotation direction aligns with the machine’s requirements. If there is a discrepancy, adjust the power phase sequence accordingly.

4. Motor Lubrication

Maintain the motor’s lubrication by replenishing lithium-based grease (ZL-3) every two weeks. Add the grease through the oil cup, except for sealed bearings, which do not have an oil cup.

5. Bearing Inspection

After 1500 hours of operation, inspect the bearings of the linear vibrating screen. Replace them immediately if they show signs of serious damage to prevent further issues.

6. Insulation Resistance Check

If the machine has been idle for an extended period, measure the insulation resistance before use. It should exceed 0.5 megohms when measured with a 500-volt megohmmeter.

Daily Maintenance of Linear Vibrating Screen

Before Starting

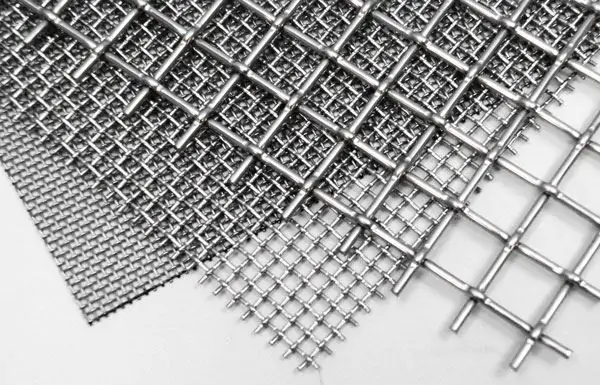

- Mesh Inspection: Check for any damage to the coarse and fine meshes.

- Ring Locking: Ensure all sets of rings are properly locked.

During Operation

- Noise Monitoring: Pay attention to any abnormal noises.

- Current Stability: Ensure the current remains stable throughout operation.

- Vibration Check: Monitor the machine for any unusual vibrations.

After Use

Clean the linear vibrating screen thoroughly after each use to maintain its efficiency and longevity.

Regular Maintenance of Linear Vibrating Screens

- Mesh and Spring Inspection: Regularly check for fatigue and damage in the coarse and fine meshes as well as the springs.

- Body Parts Inspection: Inspect the machine body for any damage resulting from vibration.

- Lubrication: Regularly lubricate parts that require it to ensure smooth operation.

Conclusion

Adhering to these use and maintenance guidelines for your linear vibrating screen can significantly enhance its performance and extend its operational life. Regular inspections, proper lubrication, and immediate replacement of damaged parts are crucial practices. By maintaining your equipment diligently, you ensure efficient and reliable sorting of materials, contributing to the overall productivity of your operation.