With corrosion resistance, high strength and durability, 304 stainless steel screen mesh is an important accessory in vibrating sieve screening operations. Especially in the chemical, food, pharmaceutical, mining and other industries, the vibrating screen needs to deal with wet, high temperature or corrosive materials for a long time, 304 stainless steel screen can effectively extend the service life of the screen.

This article will introduce in detail the characteristics of 304 stainless steel screen mesh, the key role in the vibrating screen, and how to choose the right 304 stainless steel screen mesh to optimize the screening effect, to help you improve the production efficiency and reduce the maintenance cost.

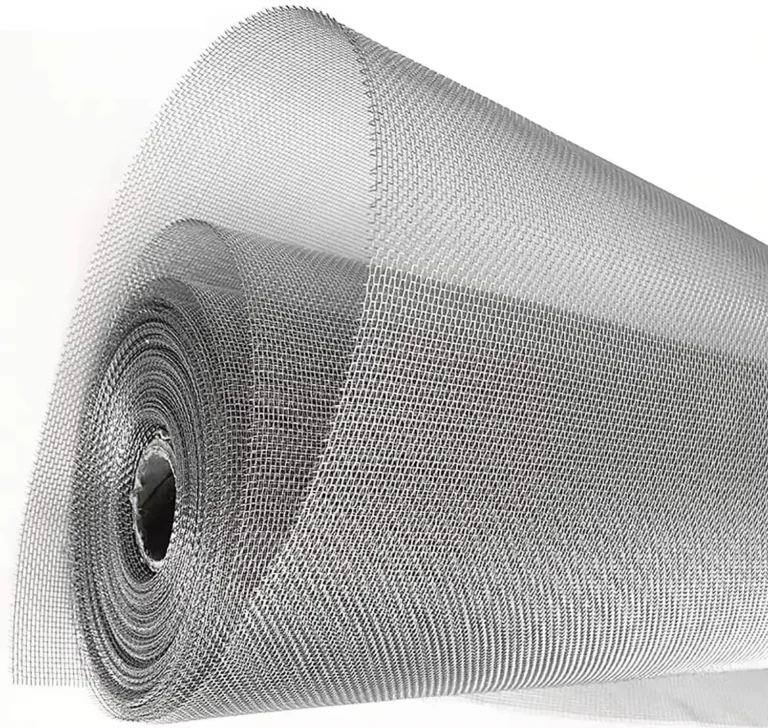

Manufacturing Process of 304 Stainless Steel Woven Mesh

The weaving techniques for 304 stainless steel vary widely, and the mesh count and tear resistance of the resulting screens differ depending on the specific weaving method employed. Different weaving processes for stainless steel woven mesh are typically distinguished by the interlacing patterns of the stainless steel warp and weft wires, commonly utilizing plain weave, twill weave, or dense weave techniques.

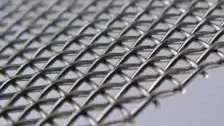

Plain Weave

Each warp wire alternately passes over and under every weft wire. Warp and weft wires share the same thickness, with threads woven at a 90-degree angle. This simple structure offers high tensile strength, making it suitable for standard screening applications.

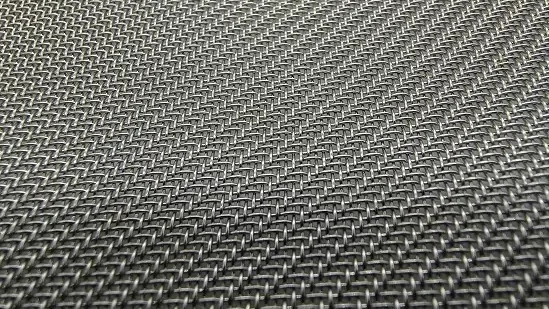

Twill Weave

Each warp thread alternately passes over and under every two weft threads, while each weft thread alternately passes over and under every two warp threads. This enhances mesh flexibility and reduces material clogging.

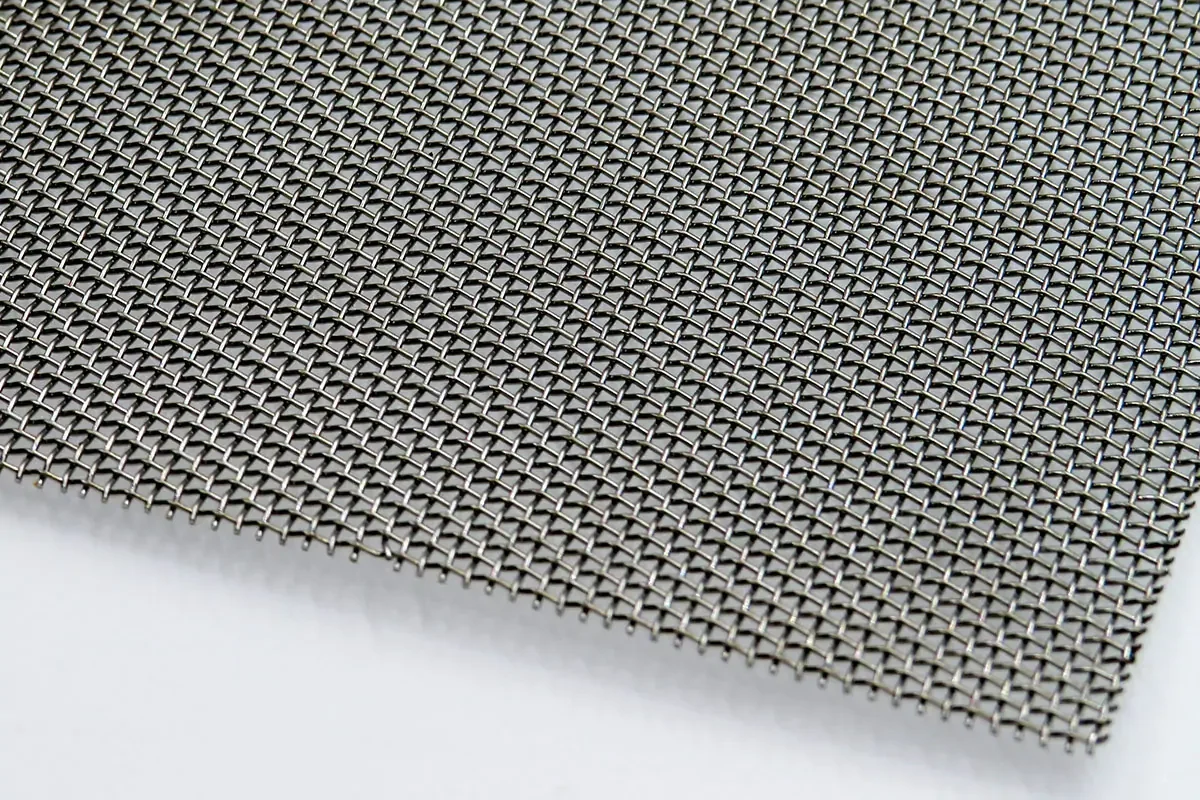

dense Weave

Warp and weft threads differ in diameter and mesh count, characterized by sparse warp threads and dense weft threads, or coarse warp threads and fine weft threads. The warp runs lengthwise, while the weft runs widthwise. Dense-weave mesh further divides into plain-woven and twill-woven varieties. Screens produced via this technique suit fine screening applications in industries like pharmaceuticals and powder metallurgy.

Additionally, 304 stainless steel woven mesh undergoes electropolishing or electrolytic treatment to enhance surface smoothness, reduce material adhesion, and impart excellent elasticity and wear resistance to the stainless steel wires. Electrolytically treated 304 stainless steel woven mesh resists deformation under prolonged impact from vibrating screens, ensuring stable screening accuracy.

Vibrating Screen Types Compatible with 304 Stainless Steel Woven Mesh

304 stainless steel possesses excellent fundamental properties and broad versatility, making it suitable for most conventional vibrating screens.

Rotary Vibrating Screen

Rotary vibrating screens utilize vertical motors driving eccentric weights to generate vibration. Featuring circular screens, they support multi-layer mesh stacking and are primarily used for fine material classification and filtration, demanding strict screening precision and uniform mesh aperture. 304 stainless steel screens offer a wide mesh size range, fully meeting the requirements of rotary vibrating screens.

Linear vibrating screen

Linear vibrating screens rely on motors driving exciters to generate vibrations, causing materials to move in a straight line across the screen surface. They feature high throughput and screening efficiency. Primarily used for continuous batch screening operations, they demand high tensile strength and wear resistance from the screens. 304 stainless steel screens fully meet these performance requirements.

Ultrasonic vibrating screen

Ultrasonic vibrating screens incorporate an ultrasonic system beyond conventional rotary vibrating screens. The high-frequency vibrations generated by ultrasonics break up material agglomerates, preventing clumping or blockages. Consequently, they require high-strength, wear-resistant screens like SUS304.

Applications of 304 Stainless Steel Woven Mesh by Mesh Size

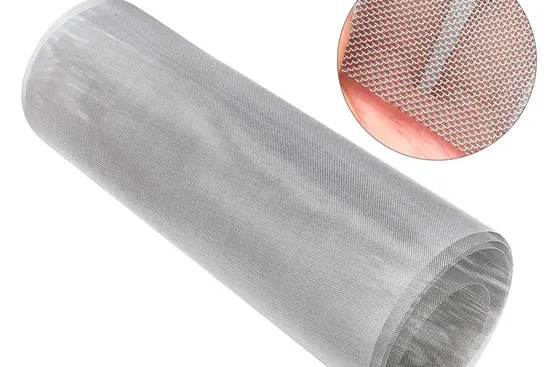

SUS304 woven mesh can be manufactured in various mesh sizes (typically ranging from 10 to 500 mesh) to suit different application requirements. Some specialized applications even utilize 5-mesh 304 stainless steel woven mesh.

304 Stainless Steel Woven Wire 20 Mesh

20 mesh 304 stainless steel woven wire mesh features larger apertures, making it suitable for screening and filtering coarse-grained materials. In construction, it screens coarse aggregates like sand and gravel to ensure project quality. In agriculture, it sifts seeds and fertilizers. Its larger apertures also enable rapid filtration with high efficiency.

304 Stainless Steel Woven Wire 60 Mesh

60-mesh 304 stainless steel woven wire is suitable for more precise industries like food processing and chemical manufacturing. It can be used to sift fine particles like flour and powdered sugar, enhancing food flavor and safety. In the chemical industry, it separates impurities from turbid liquids, improving product purity. 60-mesh stainless steel woven wire offers not only high filtration precision but also strong durability and a long service life.

304 stainless steel woven wire 120 mesh

120 mesh 304 stainless steel woven wire mesh is primarily used in industries demanding high product precision, such as screening pharmaceutical powders and infant formula.

304 stainless steel woven wire 200 mesh

200-mesh 304 stainless steel vibrating screens are typically employed in ultrasonic vibrating sieves, used only in a few high-end industries or laboratories. While its filtration speed is slow, it effectively removes impurities from products. It is suitable for high-end product lines such as pharmaceuticals and cosmetics. For example, it screens pharmaceutical powders and enhances the fineness of cosmetics.

Industrial Applications of 304 Stainless Steel Woven Mesh

Because of the advantages of 304 stainless steel woven wire mesh such as corrosion resistance, high temperature resistance, easy to clean, it is widely used in the vibrating screening industry

The following industries are commonly used in vibrating screening:

Food industry: the industry of sieving flour, starch, icing sugar, seasoning and other food-grade fine screening.

Chemical industry: sieving fertiliser, plastic granules, corrosive chemical raw materials and other industries with strong acidity and alkalinity.

Pharmaceutical industry: used for medicine powder, granules, Chinese medicine extract classification and filtration industry.

Mining and metallurgy: screening quartz sand, metal powder, coal and other industries with severe wear and tear.

Environmental protection and water treatment: used in sewage treatment, filter mesh and other corrosion-friendly industries.

Economy of 304 stainless steel woven wire mesh

Compared with 316 stainless steel, 304 stainless steel woven wire mesh has higher cost performance in common industrial environment. 316 stainless steel performs better in strong acid and high chlorine ion environment (such as seawater and chemical plating) because of molybdenum (Mo) element, but the cost is higher. While 304 stainless steel woven mesh has been able to meet the demand in most vibrating screen applications, such as food processing, general chemical screening, etc., which can guarantee the performance and reduce the purchase cost. In addition, 304 stainless steel woven mesh is easy to process, can be customised with different mesh (10 mesh 500 mesh) and wire diameter (0.03mm2mm), more suitable for different screening needs.

Conclusion:

As a manufacturer with thirty years of experience in manufacturing vibrating screening equipment, all vibrating screens produced by Sanyuantang are made of high-quality 304 stainless steel woven mesh, which has excellent abrasion resistance, corrosion resistance and screening precision. They are widely used in food, chemical, pharmaceutical and mining industries. If you need professional screening solutions or technical guidance, please feel free to contact our engineer team.