Double Decker Screen Compared to single-deck vibrating screens, double-deck vibrating screens achieve three- or four-stage material classification in a single pass through their dual- or triple-deck screen mesh design. This effectively doubles or triples the efficiency of a single-deck vibrating screen, significantly boosting production output. The double deck vibrating screen is also a core piece of equipment in the vibrating screen industry. Below, I will analyze what a Double Decker Screen is, its composition, and its working principle to provide a clearer understanding.

What is a Double-Deck Vibrating Screen?

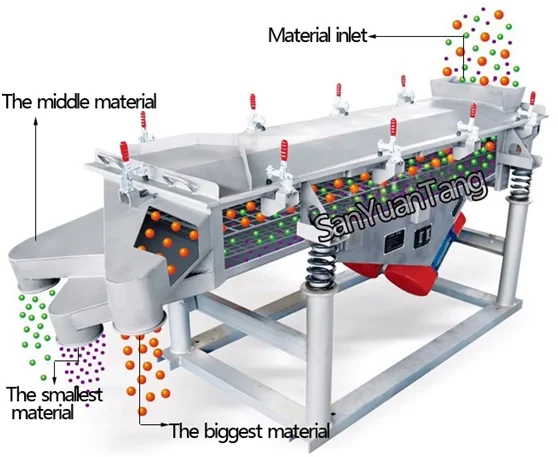

A double-deck vibrating screen is a screening device equipped with two or three layers of screens and three or four discharge ports. It can simultaneously classify raw materials into three or four distinct particle sizes, offering high screening precision, robust processing capacity, and efficiency exceeding 96%. This equipment is not only suitable for dry powders and fine granular materials but also finds specialized applications in high-temperature, high-humidity, and high-precision scenarios.

Common variants include double deck horizontal vibrating screens, double deck linear vibrating screens, double deck circular vibrating screens, and double deck horizontal vibrating screens. All feature multi-layer screen structures that can be flexibly configured based on material properties and production requirements. Explore our full vibrating screen series on our product collection page.

Structure of a Double-Deck Vibrating Screen

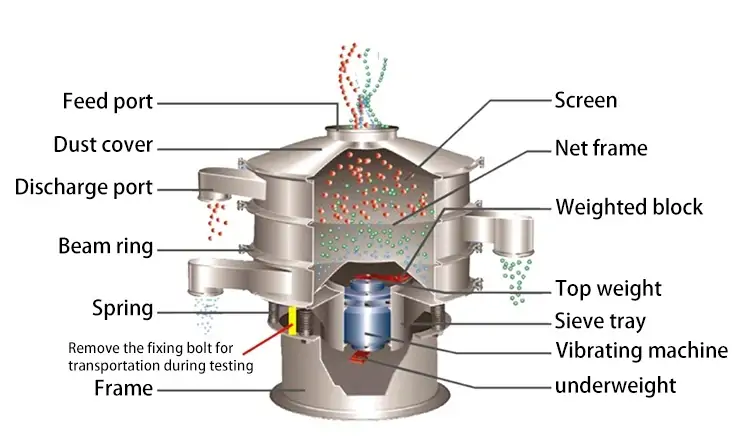

A standard double-deck vibrating screen primarily consists of:

- Vibration motor: Provides the excitation force required for screening;

- Screen box: Includes the frame, screen mesh, and fastening devices;

- Base and vibration damping springs: Support the equipment and reduce dynamic loads transmitted to the foundation;

- Feed and discharge ports: Upper layer feed, with separate discharge ports for each layer;

- Screen mesh: Typically features larger apertures on the upper layer, progressively finer on lower layers to achieve multi-stage classification.

Double Deck Screen Working Principle:

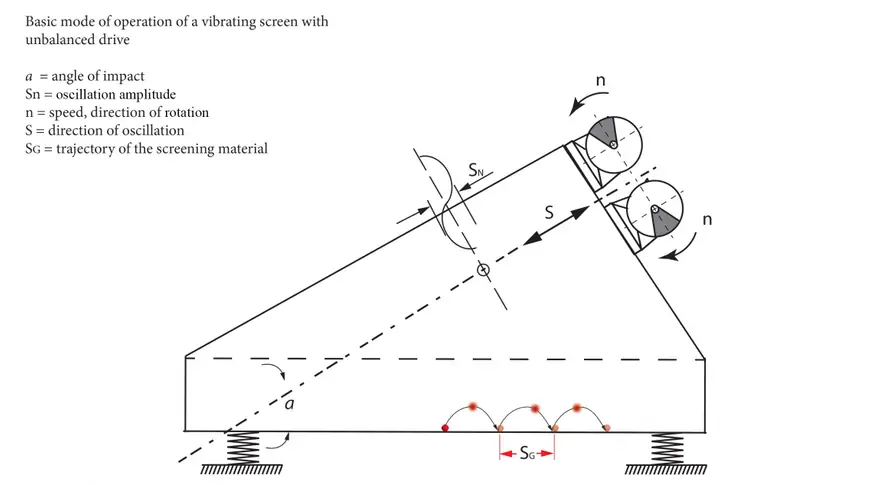

The core advantage of the double deck screen lies in its scientific structural design and motion trajectory. The specific workflow can be divided into three stages:

1. Material Entry and Initial Diffusion

After entering the screen box through the inlet, the material is rapidly dispersed from the center of the screen surface to the periphery under the influence of the circular vibratory force generated by the vibrating motor. This stage prevents material accumulation at the inlet, maximizing screen utilization.

2. Grading Process Across Dual Screens

The primary screen separates coarse particles or impurities exceeding the set particle size, discharging them through the side outlet. Material meeting the required particle size passes through the primary screen to the secondary fine screen. The second layer further screens the material, separating medium-sized particles and fine powder. Medium-sized particles discharge through the second layer’s outlet, while fine powder exits via the third layer’s outlet, achieving a “multiple-screen-in-one-machine” effect. Throughout the process, the vibrating action continuously tumbles the material, preventing screen clogging and ensuring consistent screening efficiency above 96%.

3. Vibration System

The vibration source for double-deck vibrating screens typically employs a dual-motor synchronous counter-rotation design. Centrifugal force generated by eccentric weights drives the screen box in circular motion. Amplitude can be adjusted according to material properties, ensuring coarse particles pass smoothly through the first deck while preventing fine powder from scattering due to excessive vibration.

Whether handling powdery, granular, fine powder, or micropowder materials, double-deck vibrating screens efficiently accomplish screening and classification.

Double Decker Screen Repair

Over extended use, screen mesh wear, motor aging, or loosened fasteners may compromise screening performance. Therefore, regular maintenance is essential:

- Inspect and replace screen meshes to prevent clogging or damage;

- Check vibration motors to ensure smooth operation;

- Inspect support springs and fasteners to avoid equipment malfunctions due to loosening;

- Regularly lubricate bearings to extend their service life;

Through standardized maintenance and timely repairs, double-deck vibrating screens can operate efficiently and stably over the long term.

Conclusion:

Whether for fine screening in the food industry or coarse ore classification in metallurgy, the double deck vibrating screen serves as an efficient grading solution, helping enterprises reduce production costs and enhance product quality. During daily operation, attention to routine maintenance and double decker screen repair is crucial for sustained, stable performance. For related needs or further inquiries about equipment selection, please contact our professional technical team. We will provide you with the latest solutions and equipment selection recommendations.