Spring for Vibrating Screen–Steel spring, it is a kind of metal steel, using the elasticity of the mechanical parts, has the advantages of long service life and is not affected by the ambient temperature.

We accept your customised production.

- Type: Coil

- Wire diameter:0.2mm-90mm

- Material: ASTM1066, ASTM9260, ASTM9254, ASTM5155, ASTM5160, ASTM6150 (S302, 304, 316-7) (Inconel 718, Inconel X-750, tungsten alloys)

- Surface Finish: Sprayed, coated, galvanised, flanged, etc.

- Certification: ISO 9001:2008

- Customization: Colour, size, material and other requirements.

Applications: vibro sifter, stainless steel vibrating screens, light linear vibrating screens, small heavy vibrating screen, probabilistic screens, etc.

Steel spring function in vibrating screens

- Vibration damping buffer function: the spring absorbs the vibration impact and isolates the harmful vibration, reducing the impact on the equipment and foundation.

- Support adjustment function: the spring carries the weight of the screen body and dynamically adjusts the amplitude to adapt to different screening equipment.

- Reset and stabilise function: the spring automatically resets and maintains the vibration balance, so that the screen box operates stably and prevents deflection or damage.

Technical parameters

| Model | Inner diameter D mm | Overall height L mm | Steel wire diameter d mm |

| Φ70×150×Φ8 | 70 | 150 | 8 |

| Φ70×150×Φ10 | 70 | 150 | 10 |

| Φ70×150×Φ12 | 70 | 150 | 12 |

| Φ70×180×Φ12 | 70 | 180 | 12 |

| Φ70×180×Φ14 | 70 | 180 | 14 |

| Φ70×180×Φ16 | 70 | 180 | 16 |

| Φ70×180×Φ18 | 70 | 180 | 18 |

| Φ76×150×Φ10 | 76 | 150 | 10 |

| Φ36×145×Φ4.5 | 36 | 145 | 4.5 |

| Φ36×145×Φ5.0 | 36 | 145 | 5.0 |

| Φ36×145×Φ5.5 | 36 | 145 | 5.5 |

| Φ36×145×Φ6.0 | 36 | 145 | 6.0 |

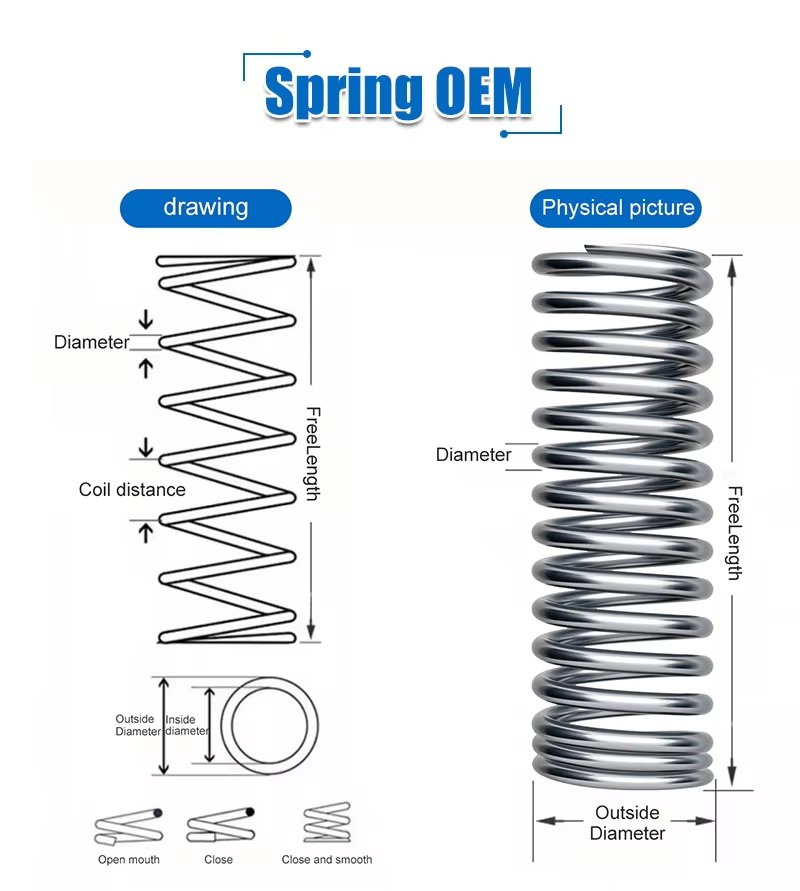

Customized compression spring

We can personalise the product according to your needs,

You only need to provide drawings and samples, design and specification requirements, we can help you to complete the product is production.

Selection of Spring for Vibrating Screen

The selection of vibrating screen spring is very important, in order to effectively make the equipment damping, need to consider the specifications of the vibrating screen parameters, excitation force output characteristics and dynamic and static loads and other key factors. In practical application, if there are special requirements on the number of spring arrangement or distribution, it is recommended to seek technical support from professional vibrating screen manufacturers. The spring configuration without professional calculation may be difficult to achieve the ideal damping effect.

If you have other needs, you can always consult us.

Custom Spring for Vibrating Screen

To provide the most suitable spring solution for your vibrating screen, please provide the following customised parameters:

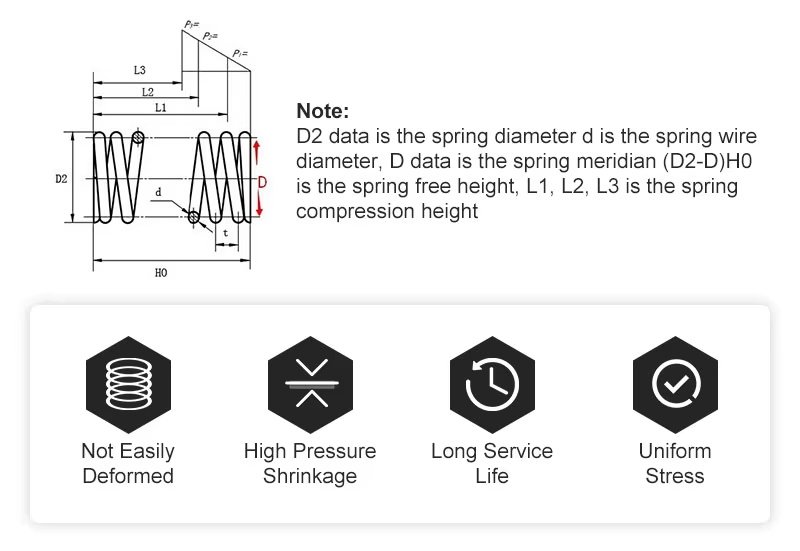

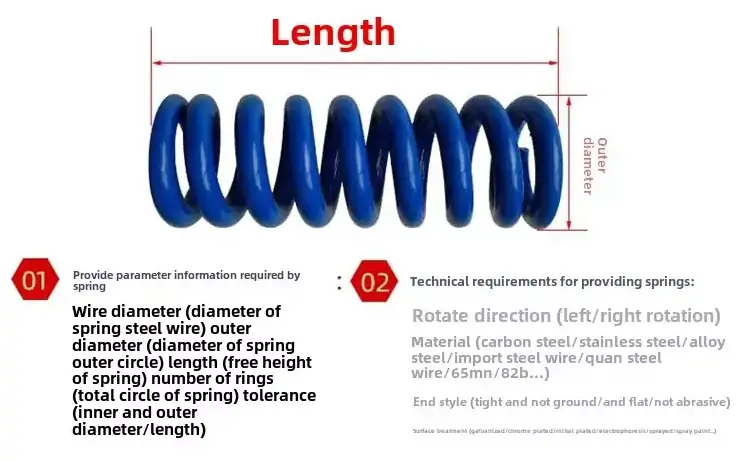

- Wire Diameter(mm): Provide the specific diameter value of the spring wire.

- Spring Outer Diameter(mm): Specify the size of the outer diameter of the spring.

- Spring Free Height(mm): Specify the height of the spring in its free state.

- Total number of spring coils: Fill in the total number of coils or effective number of coils of the spring.

- Tolerance requirements: Select or customise the tolerance range of the inner and outer diameters and length.

- Direction of rotation: Determine the direction of rotation of the spring (left or right).

- Material Selection: Select the spring material from carbon steel, stainless steel, and other options.