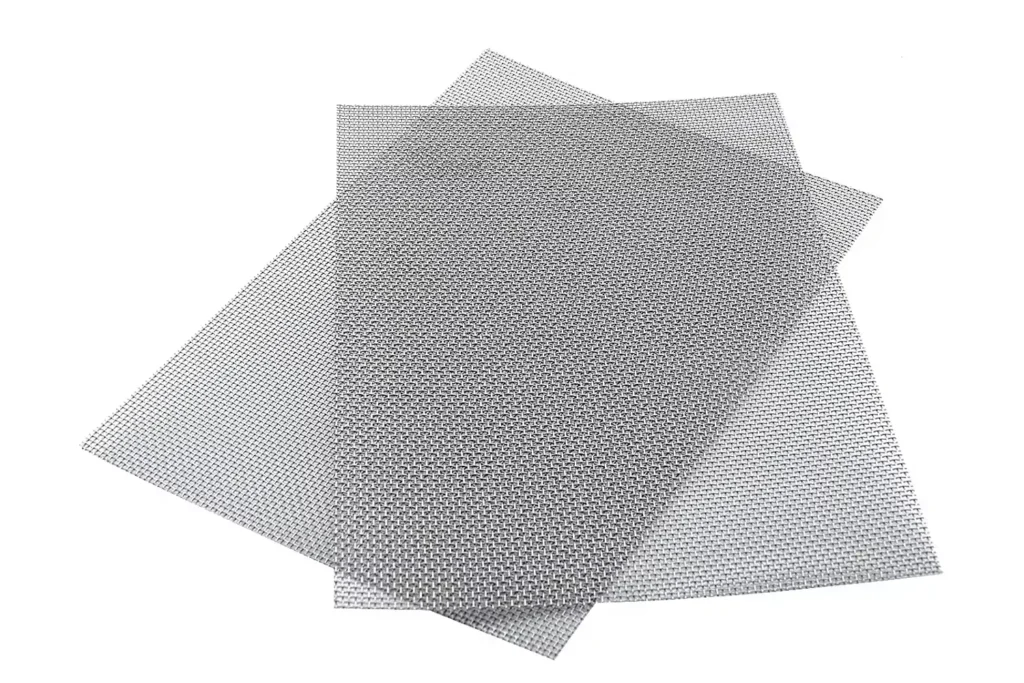

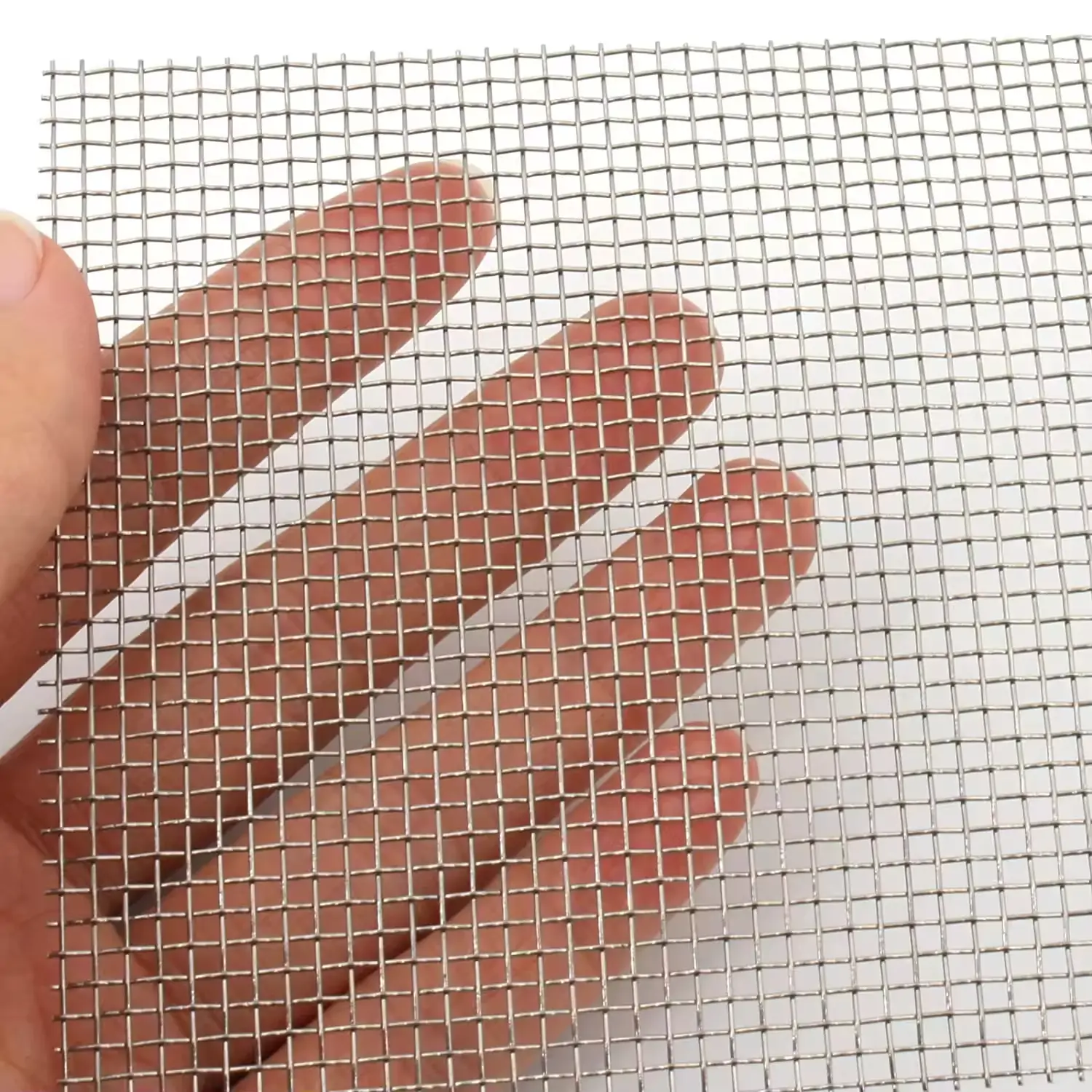

Fine stainless steel wire mesh is made of high quality 304, 304L, 316, 316L and other stainless steel wires, which is corrosion-resistant, high temperature-resistant, high strength, long life and other characteristics. The mesh range can be from 2mesh to 635mesh, and the wire diameter can be 0.018mm~1.8mm, which can meet the needs of different precision screening, filtration and so on.

- Meterial: ss304/ss304l/ss316/ss316l etc

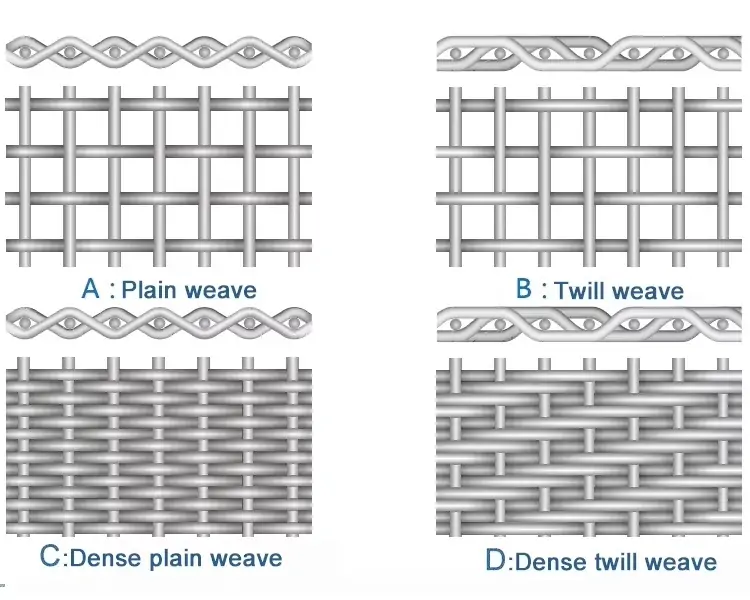

- Type: Weave Wire Mesh

- Mesh Hole: 2 mesh to 635 mesh

- Wire Diameter: 0.018 mm to 1.8 mm

- Weave Style: Plain Weave

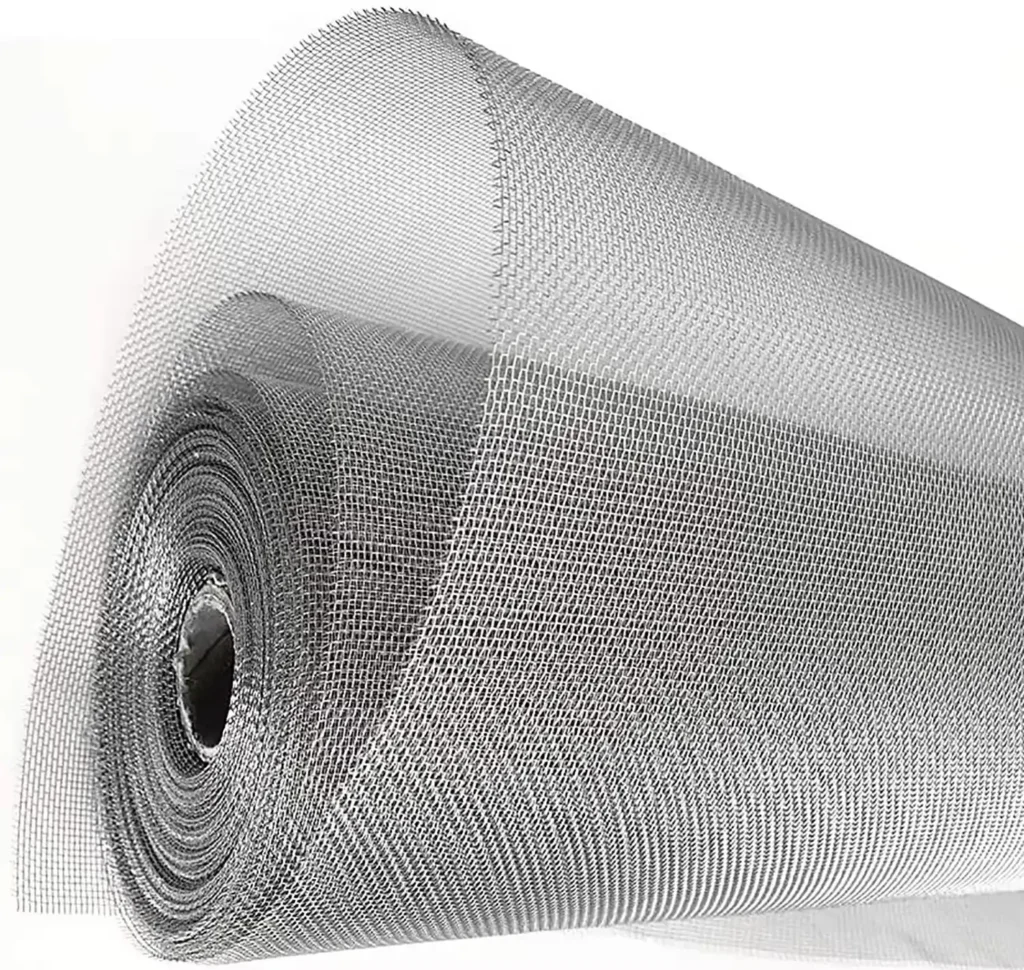

- Roll Width :0.5m , 1m, 1.2m,1.5m, 1.8m,2.0m, 3m,4m, 5m, 8m… Max width 18m.

- Roll Length:30m/roll, 50m/roll or custom

Features

Fine stainless steel wire mesh with its high precision weaving process, excellent abrasion resistance and impact resistance, plays an important role in vibrating screening equipment, the main functions include:

- High-efficiency screening: Can produce 2-635 mesh screens of various specifications, accurate separation of particles, powders and slurries, commonly used in the chemical industry, food, mining and other industries of particle size screening.

- Wear-resistant and impact-resistant: 304/316 stainless steel can be used, the material is high hardness, which can increase the damage of high frequency vibration and material impact, thus increasing the service life long.

- Anti-blocking hole design: using plain weave process, stable structure, uniform mesh; and can increase electrolytic polishing treatment to enhance the mobility and reduce the clogging of sticky materials.

- Strong corrosion resistance: 316/316L stainless steel material is resistant to acid and alkali, rust and corrosion, adapting to humidity, high temperature and chemical and other harsh environments

- Customisation: Sanyuantang Machinery supports customised Fine Stainless Steel Wire Mesh, which is compatible with Circular Vibrating Screens, Linear Screens, Ultrasonic Vibrating Screens and other various equipment.

Use of Fine Stainless Steel Wire Mesh

In the vibrating screen industry, ultrasonic vibrating screen mesh, circular vibrating screen mesh, linear vibrating screen mesh and many other types of vibrating screen mesh, are used Fine Stainless Steel Wire Mesh, because it has the characteristics of abrasion-resistant, impact-resistant, corrosion-resistant, etc., and through the differentiation of the weaving process, it can satisfy the demand for precision screening in different industries, such as food, pharmacy, mining and so on.

Custom Fine Stainless Steel Wire Mesh

Sanyuantang Machinery specialises in the custom production of all kinds of Fine Stainless Steel Wire Mesh, with a variety of precision weaving processes available.

We have a complete production system and can customise Fine Stainless Steel Wire Mesh with different weaving methods, mesh sizes and wire diameters according to customers’ specific needs, so as to meet your different needs in screening production equipment.

With mature technology and flexible production capacity, we are able to provide high-precision, wear-resistant customised screen solutions for food, pharmaceutical, mining and other industries.

We will strongly support your screening needs with professional customised screen solutions and superior quality services!

Custom Fine Stainless Steel Wire Mesh

To ensure the perfect mesh for your needs, please provide:

Mesh Size: 2 mesh to 635 mesh

Wire Diameter: 0.018 mm to 1.8 mm

Naterials: ss304/ss304l/ss316/ss316l etc

Weave Type: Plain, twill, Dutch, or special weave.

Panel Size: e.g., 1m × 2m (or custom shape: round, rectangular).

Edge/Frame: Hemmed, welded frame, or flanged.

Environment: High heat, chemicals, food-grade, etc.

Load: Static/dynamic pressure (e.g., 10kg/m²).

Submit a Quick Quote

Specification of plain weave

| Mesh/inch | Wire Diameter(mm) | Aperture (mm) | Mesh/inch | Wire diameter(mm) | Aperture (mm) |

| 2mesh | 1.8 | 10.9 | 60mesh | 0.15 | 0.273 |

| 3mesh | 1.6 | 6.866 | 70mesh | 0.14 | 0.223 |

| 4mesh | 1.2 | 5.15 | 80mesh | 0.12 | 0.198 |

| 5mesh | 0.91 | 4.17 | 90mesh | 0.11 | 0.172 |

| 6mesh | 0.8 | 3.433 | 100mesh | 0.1 | 0.154 |

| 8mesh | 0.6 | 2.575 | 120mesh | 0.08 | 0.132 |

| 10mesh | 0.55 | 1.99 | 140mesh | 0.07 | 0.111 |

| 12mesh | 0.5 | 1.616 | 150mesh | 0.065 | 0.104 |

| 14mesh | 0.45 | 1.362 | 160mesh | 0.065 | 0.094 |

| 16mesh | 0.4 | 1.188 | 180mesh | 0.053 | 0.088 |

| 18mesh | 0.35 | 1.06 | 200mesh | 0.053 | 0.074 |

| 20mesh | 0.3 | 0.97 | 250mesh | 0.04 | 0.061 |

| 26mesh | 0.28 | 0.696 | 300mesh | 0.035 | 0.049 |

| 30mesh | 0.25 | 0.596 | 325mesh | 0.03 | 0.048 |

| 40mesh | 0.21 | 0.425 | 350mesh | 0.03 | 0.042 |

| 50mesh | 0.19 | 0.318 | 400mesh | 0.25 | 0.0385 |

Specification of Twil weave

| Mesh/inch | wire diameter(mm) | Aperture(mm) | Mesh/inch | wire diameter(mm) | Aperture(mm) |

| 100 | 0.14 | 0.114 | 325 | 0.035 | 0.0443 |

| 120 | 0.1 | 0.111 | 350 | 0.032 | 0.0405 |

| 150 | 0.09 | 0.079 | 400 | 0.03 | 0.0335 |

| 180 | 0.07 | 0.071 | 450 | 0.026 | 0.0304 |

| 200 | 0.06 | 0.067 | 500 | 0.025 | 0.0258 |

| 250 | 0.045 | 0.0566 | 600 | 0.018 | 0.0243 |

| 300 | 0.04 | 0.0446 | 635 | 0.018 | 0.022 |

Specification of Plain Dutch Weave

| Mesh/inch | Absolute micron retention (µm) | Weight(kg/㎡) | Cloth Thickness(mm) |

| 80×300 | 32-36 | 0.98 | 0.25 |

| 80×400 | 32-45 | 0.82 | 0.23 |

| 50×250 | 56-63 | 1 | 0.32 |

| 50×280 | 71-75 | 1 | 0.32 |

| 40×200 | 75-80 | 1.3 | 0.4 |

| 30×150 | 80-100 | 1 | 0.5 |

| 24×110 | 100-112 | 2.5 | 0.76 |

| 22×140 | 140-170 | 2.1 | 0.66 |

| 20×150 | 160-180 | 1.55 | 0.5 |

| 20×150 | 170-190 | 1.6 | 0.55 |

| 18×100 | 200-210 | 2.05 | 0.69 |

| 14×110 | 220-240 | 2.15 | 0.72 |

| 12×95 | 240-260 | 2.3 | 0.79 |

| 14×88 | 280-300 | 3.15 | 0.76 |

| 10×90 | 270-290 | 2.5 | 0.93 |

| 12×64 | 280-300 | 4.1 | 1.21 |