The rubber spring for vibrating screen is a high-elastic body. The material is made of ordinary rubber. It is a spring that uses rubber elasticity to cushion and absorb shock.

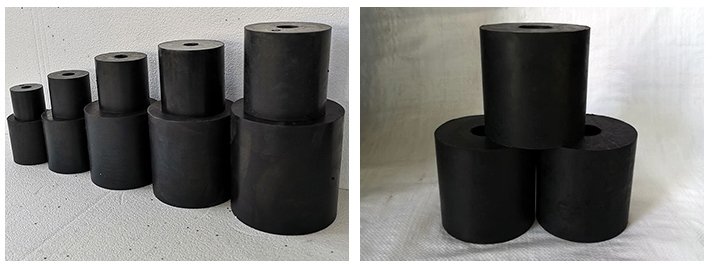

- Product Name: Compound Rubber Spring, Shock Absorber Rubber Coil Spring Gasket

- High temperature resistance: 0°C-70°C (ordinary rubber)

- Material: NR, Silicon, EPDM, Polyurethane

- Usage: Vibrating Screen, Industrial Shock Absorber

- Size: OD50mm-300mm or according to your requirement

- Resistance: Anti-corrosive, high wear-resistant, etc.

- Customisation: Can be customised according to drawing

Applications: Light linear vibrating screens, stainless steel vibrating screen, vibrating feeders, vibrating screen, etc. Springs of this type are also used in vibration platforms with a bearing capacity of more than 1 ton.

What is rubber spring for vibrating screen

Rubber spring for vibrating screen is made of ordinary rubber with small modulus of elasticity, unrestricted shape and large elastic deformation. The rubber spring has large internal resistance, good damping effect, small resonance field and long service life. Compared with traditional metal springs, rubber springs have the advantages of corrosion resistance, no need for lubrication, adjustable damping characteristics, etc., and can work stably under the environment of -30℃ to +80℃.

Rubber spring for vibrating screen has good cold resistance, airtightness, waterproof and electric insulation, according to different needs, the rubber spring can be designed as cylindrical, conical or rectangular and other structures, and can be achieved by adjusting the hardness of the rubber and the number of layers of internal cord. Different bearing and damping effects can be used in vibrating screens, vibrating feeders, vibrating crushers, vibrating platforms and other machinery.

If there is such a requirement must consult a professional vibrating screen manufacturer to get professional advice, otherwise it may not achieve the expected damping effect.

Selection of vibrating screen Rubber springs

The selection of vibrating screen rubber springs directly affects the performance, stability, and service life of the equipment, as well as key parameters such as the vibration frequency and amplitude of the vibrating screen. The following is a detailed introduction to two different types of rubber vibrating screen springs:

Rubber spring: It is a kind of high elastic body. It is made of ordinary rubber. It has a small elastic modulus and has a large elastic deformation after being loaded. It absorbs shock and vibration and can be loaded in multiple directions at the same time, but it has high temperature resistance. And oil resistance is worse than steel springs. If there are special requirements, it can be made of oil-resistant rubber.

Composite spring: The composite rubber spring is composed of a metal coil spring and the high-quality vulcanized rubber wrapped around it. lt integrates the advantages of metal springs and rubber springs, and overcomes the shortcomings of metal springs, such as rigidity, high working noise, low bearing capacity of rubber springs, poor shape and mechanical performance stability.

Product Parameters

Name: Composite rubber spring

Material: Natural rubber

Specification: Support customization

Features:Good resilience,large load bearing, strong compression resistance,unique structure,easy maintenance

Application: Widely used in vibrating screen, vibrating feeder and supporting vibration isolation equipment of other vibrating machinery

| Rubber Spring Specifications | ||||||

| Model (D×H×Φ, mm) | Outer Dia. (mm) | Inner Dia. (mm) | Height (mm) | Working Deformation (cm) | Stiffness (kg/cm) | Static Load (kg) |

| Φ90×150×Φ38 | 90 | 38 | 150 | 2 | 150–350 | 300–700 |

| Φ90×150×Φ40 | 90 | 40 | 150 | 2 | 150–350 | 300–700 |

| Φ148×260×Φ80 | 148 | 80 | 260 | 3 | 180–600 | 500–1800 |

| Φ150×250×Φ80 | 150 | 80 | 250 | 3 | 180–600 | 500–1800 |

| Φ150×265×Φ80 | 150 | 80 | 265 | 3 | 180–600 | 500–1800 |

| Φ150×265×Φ92 | 150 | 90 | 265 | 3 | 180–600 | 500–1800 |

| Φ155×290×Φ60 | 155 | 60 | 290 | 3 | 240–660 | 700–2000 |

| Φ155×290×Φ62 | 155 | 62 | 290 | 3 | 240–660 | 700–2000 |

| Φ155×290×Φ75 | 155 | 75 | 290 | 3 | 240–660 | 700–2000 |

| Φ160×236×Φ94 | 160 | 94 | 236 | 2–3 | 250–1000 | 750–3000 |

| Φ160×240×Φ94 | 160 | 94 | 240 | 2–3 | 250–1000 | 750–3000 |

| Φ180×270×Φ80 | 180 | 80 | 270 | 3 | 300–1000 | 900–3000 |

| Φ180×290×Φ80 | 180 | 80 | 290 | 3 | 300–1000 | 900–3000 |

Custom Rubber Spring for Vibrating Screen

To provide the most suitable rubber spring solution for your vibrating screen, please provide the following customised parameters:

- Material: Natural Rubber / Synthetic Rubber / High Damping Rubber

- Load Capacity: Static 500-10000kg, Dynamic 200-8000kg

- Dimensions: Diameter 100-500mm, Height 50-300mm, Customised shapes are available

- Hardness: Adjustable Shore A 40°-80°.

- Temperature resistance: Standard -20°C to 70°C, High temperature -30°C to 100°C

- Environmental suitability: UV/oil/chemical resistant

- Mounting: Screw/threaded post/customised bracket

- Special requirements: Flame retardant/anti ageing/colour customisation