Screw feeding machine is a mechanical automatic feeding equipment for various powdery and granular materials, which can be customised according to the equipment needs for feeding, height, feeding speed and other parameters. Screw feeding machine with hopper is widely used in food, medicine, chemical, plastics, feed and other industries for conveying powdery and granular materials. It can be used with rotary vibrating screen, all kinds of crusher, mixer, packaging machine, etc. to achieve material level tracking and automatic feeding, and can also be used separately in other occasions. This article will give you an introduction to the role of the spiral feeding machine?

The main function of screw feeding machine

Automated Material Conveying

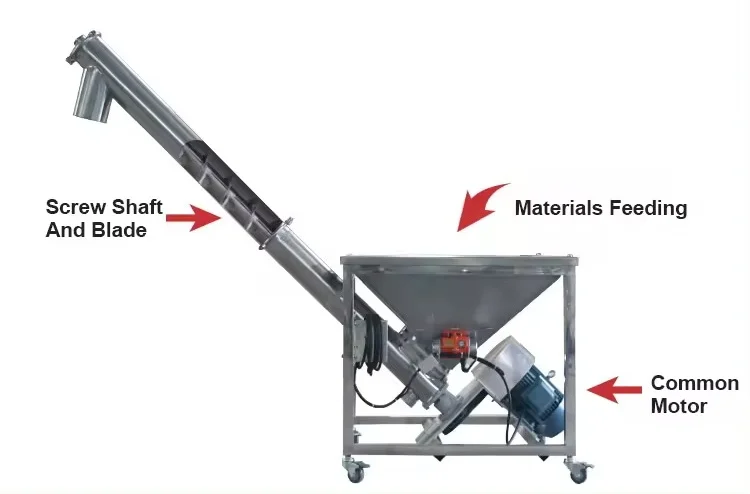

Screw feeding machine can realise automated material conveying, reduce manual intervention and improve production efficiency. It rotates the screw blades driven by the motor to continuously and stably convey materials from the storage bin or hopper to the specified position, which is suitable for production scenarios requiring frequent or large amount of material supply.

Precise control of loading speed and height

The Screw Loader can be customised with loading speeds and heights to suit production requirements, ensuring precise material conveying. By adjusting the speed of the motor or replacing different specifications of the screw blades, the amount of material conveyed can be flexibly controlled to meet the requirements of different processes.

Adapt to a variety of materials

Screw feeding machine is suitable for conveying powder, granule and small granule mixtures. Its structural design can be adjusted according to the characteristics of the material (such as fluidity, density, humidity, etc.) to ensure that the material is not blocked or stratified in the conveying process.

Matching with other equipment

Screw Loader can be matched with rotary vibrating screen, crusher, mixer, packaging machine and other equipment to achieve the automation linkage of the production line. For example, in the food industry, it can cooperate with packaging machine to realise the automatic feeding and packaging of materials; in the chemical industry, it can be combined with mixer to ensure the uniform mixing of raw materials.

Flexible installation

Screw Loader supports vertical or inclined installation, which can adapt to different production sites and process layouts. Its compact design allows it to operate efficiently in space-constrained environments, while facilitating integration with other equipment.

The importance of screw loaders in industrial production

Improve production efficiency

The automated conveying function of the screw loader greatly reduces the time and error of manual operation and significantly improves production efficiency. Especially in production lines that require continuous feeding, its stable conveying capacity ensures the smoothness of the production process.

Ensure product quality

By accurately controlling the conveying volume and speed of materials, Screw feeding machine can avoid uneven material proportioning or waste caused by improper human operation, thus ensuring the stability of product quality.

Reduce production costs

The automated operation of the screw feeding machine reduces the need for manpower and lowers labour costs. At the same time, its efficient conveying capacity also reduces material waste, saving production costs for enterprises.

Enhance production safety

In chemical and pharmaceutical industries, certain materials may be corrosive or toxic. The closed design of screw feeding machine can effectively reduce the contact between materials and the outside world, reducing environmental pollution and health risks of operators.

Adapting to diversified production needs

Screw Loaders can be customised according to the characteristics of different industries and materials, e.g. using stainless steel to meet the high hygiene standards of the food and pharmaceutical industries, or adding explosion-proof design to meet the safety requirements of the chemical industry.

Application Scenarios of Screw Feeding Machine

Food industry

In food processing, screw loaders are commonly used to convey raw materials such as flour, sugar, salt and milk powder. Its hygienic design and easy cleaning meet the strict requirements of the food industry.

Pharmaceutical Industry

In pharmaceutical production, screw loaders are used to convey raw materials such as pharmaceutical powders and granules to ensure the purity and precise proportioning of the materials to meet GMP standards.

Chemical Industry

In the chemical industry, screw loaders are suitable for conveying materials such as pigments, plastic granules, fertilisers, etc. Their corrosion-resistant and explosion-proof design can adapt to the harsh production environment.

Plastics and Feed Industry

Screw Loaders are used to convey plastic granules in the plastics industry and feed ingredients in the feed industry, where their efficient conveying capacity provides for mass production.

Conclusion

Screw loaders play an important role in several industries as an efficient and stable automated conveying equipment. Its core functions include automatic conveying, precise control, adapt to a variety of materials, flexible installation, etc., can significantly improve production efficiency, ensure product quality and reduce production costs. With the continuous development of industrial automation, the scope of application of screw feeding machine will be further expanded to provide more reliable solutions for the production of various industries.

If you are interested in screw feeding machine or need customised service, please feel free to contact us, we will provide you with professional technical support and solutions.