What is a vacuum conveyor?

Vacuum Feeder Conveyor, also called vacuum conveyor, is a dust-free closed pipe conveying equipment which uses vacuum pump to convey granular and powdery materials. It makes the inlet of suction nozzle and the whole system in a certain vacuum state, powder and granular materials are sucked into the nozzle along with the outside air, forming the material air flow, through the suction pipe to the hopper, in the hopper for air and material separation. The separated materials enter into the receiving equipment. Now it is widely used in chemical industry, pharmaceutical industry, foodstuff industry, metallurgy industry, building materials industry, agriculture and sideline industry and other light and heavy industries! It can convey powder, granule and small block materials efficiently and dust-free, reduce manual intervention and improve production efficiency.

What is the principle of vacuum conveying?

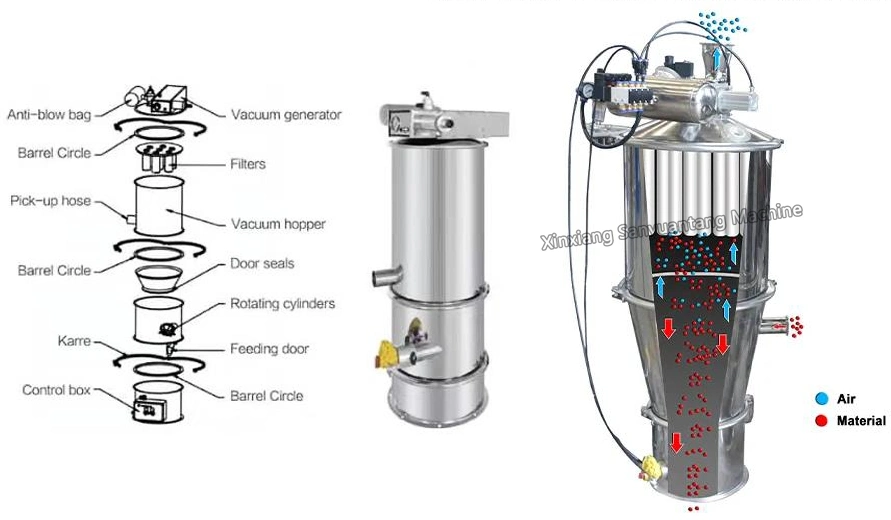

Working Principle

The operation of vacuum loading machine is formed by the cyclic process of ‘negative pressure adsorption – filtration and separation – positive pressure unloading’, the following are the detailed steps:

1. Vacuum generation stage

Negative pressure (usually -0.4~-0.6bar) is generated in the conveying pipeline by vacuum pump.

The material is sucked into the conveying pipe from the suction port (e.g. tonne bag, hopper) under the effect of air pressure difference.

2. Material separation stage

The air-material mixture enters the filtering bin, the filter element (material: polyester fibre/metal sintered/PTFE) blocks the material, and the clean air is discharged.

The material accumulated on the surface of the filter element is automatically cleaned by backblowing to maintain air permeability.

3. Unloading stage

The vacuum pump stops working, the butterfly valve at the bottom of the silo opens, and the materials fall into the downstream equipment (e.g. mixer, packaging machine) by gravity.

Some models are equipped with vibrators or fluidising devices to assist the unloading of viscous materials.

4.Cycle control

The suction-unloading cycle (usually 10~60 seconds/time) is set by PLC or time relay to realise continuous automatic material supply.

Key Components and Functions

Vacuum pump : generates negative pressure, power source (rotary vane pump / Roots pump / water ring pump).

Filtration system : separates material and air, filter element precision 1~50μm optional.

Blowback device : compressed air pulse to clean the filter element to prevent clogging.

Silo and Valve : Temporary storage of materials, pneumatic butterfly valve control discharge.

Control system : Regulate conveying frequency and pressure, support manual/automatic mode.

What is the difference between a vacuum conveyor and a pneumatic conveyor?

While both vacuum conveyors and pneumatic conveyors transport materials using airflow, their working principles, applications, and system designs differ significantly:

| Feature | Vacuum Conveyor | Pneumatic Conveyor |

|---|---|---|

| Working Principle | Uses vacuum suction (negative pressure) to pull materials | Uses compressed air (positive pressure) to push materials |

| Best For | Short-distance (<30m), precision handling (e.g., powders, granules) | Long-distance, high-capacity transport (e.g., pellets, dense materials) |

| System Components | Vacuum pump, filters, separation chamber | Air compressor, pressure vessels, blow tanks |

| Material Compatibility | Fine powders, fragile granules, pharmaceuticals | Larger particles, abrasive materials, minerals |

| Containment | Fully enclosed, dust-free (ideal for cleanrooms) | Potential dust leakage (requires additional filtration) |

| Energy Efficiency | Lower energy use for short distances | Higher energy demand for long-distance transport |

| Maintenance | Easy (fewer moving parts, focus on filter cleaning) | Complex (higher wear due to pressurized systems) |

How to Choose?

- Pick a Vacuum Conveyor if: You need clean, short-range transfer (e.g., food, pharma, or sensitive powders).

- Pick a Pneumatic Conveyor if: You transport bulky/heavy materials over long distances (e.g., cement, plastics, or grains).

How to use a vacuum Feeder Conveyor?

Using a vacuum feeder conveyor is simple, but the correct setup ensures optimal performance:

- Installation: Connect the loader to the vibrating screen or production line. Make sure all connections are secure.

- Material loading: Put the material into the feed hopper. Adjust suction power according to material type and density.

- Operation: Start the machine and monitor material flow. Use the control panel to adjust speed and feed rate.

- Shutdown: After use, clean the hopper and filter to prevent clogging and ensure service life. For detailed instructions, refer to the user manual or contact our technical support team.

Applications of Vacuum Feeder Conveyors

Vacuum feeder conveyors have a wide range of uses. Because they are transported in closed pipes, dust pollution to the environment can be avoided during the transmission process. They can be used in a variety of industries, including:

- Food processing: Handles powders, granules and fine ingredients without causing contamination.

- Pharmaceutical: Able to handle precise dosages and maintain hygiene standards.

- Chemicals: Safely transfer abrasive or hazardous materials.

- Plastics: Efficiently feed granules and powders into molding machines.

- Agriculture: Distribute seeds, fertilizers and other granular materials.

Conclusion

Through the above, we understand what is Vacuum Conveyor, and its working principle, and the difference between Vacuum Conveyor and Pneumatic Conveyor, which has become an important material conveying equipment in the modern industry by virtue of its advantages of airtight and dust-free, high degree of automation and easy maintenance. Compared with pneumatic conveying machine, it is more suitable for short distance and high cleanliness requirement scene. Enterprises should make a reasonable selection based on material characteristics, conveying distance, industry standards and other factors.

If you are considering the introduction of vacuum loading system, it is recommended to initiate an enquiry now, as a professional manufacturer for more than 30 years, we have the experience and ability to help you provide professional advice, so that the equipment you purchase is perfectly matched with your production needs!

Related Articles

- Vacuum Feeder Applications in Pharmaceutical Industry

- Vacuum Feeding Machine Core Components Analysis

- How to Choose an Right Inclined Screw Conveyor Model?

- How to Select a Suitable Vibrating Screen?

- What is Blender in Pharma Industry

- V Blender Working Principle, Design, Parts, Capacity

- How To Use V Mixer Machine And Precautions