Rubber Sealing Strip for Vibrating Screen is a sealing component used in vibrating screen equipment. Its function is to seal the connections between the screen frame, screen cover, and other parts during the operation of the vibrating screen, preventing material leakage, dust dispersion, and reducing vibration noise. It is primarily used in various types of vibrating screening equipment, including circular vibrating screens, linear vibrating screens, high-frequency vibrating screens, and mining vibrating screens.

We accept your customised production.

- Material: Rubber, silicone, EPDM, polyurethane, or custom

- Color: Black, white, or custom

- Size: Customizable

- Hardness: 40-80 or customized

- Application: Various types of vibrating screening equipment

Rubber Sealing Strip for Vibrating Screen Types

Classified by Shape

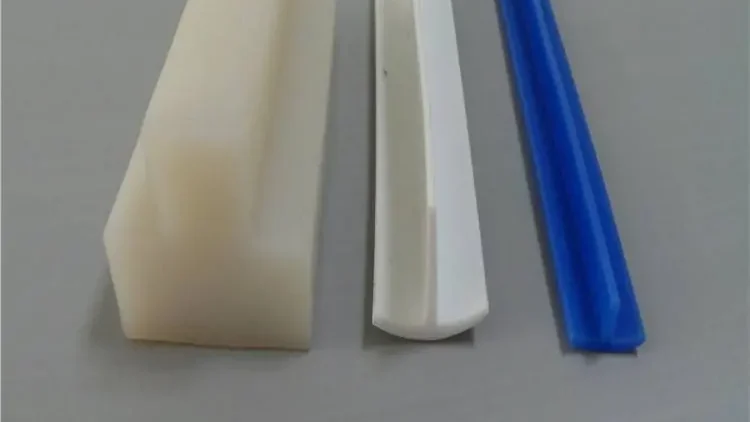

- Strip-shaped sealing strip: This is the most common type, featuring a long, strip-like shape with a simple structure and easy installation, suitable for the straight-type installation slots of most vibrating screens.

- Round Sealing Strip: With a circular cross-section, it offers excellent elasticity and sealing performance, suitable for special-shaped installation slots or areas requiring 360-degree sealing.

- Custom-Shaped Sealing Strip: Designed in various special shapes such as U-shaped, L-shaped, or wavy, based on the specific structure of the vibrating screen and sealing requirements, it better adapts to complex installation environments and provides more reliable sealing performance.

Classified by installation method

Slot-type sealing strip: Connected to the screen body installation slot via a slot. During installation, simply insert the sealing strip into the slot. Installation and removal are relatively convenient, suitable for applications requiring frequent replacement of sealing strips.

Adhesive-type sealing strip: Attached to the screen body installation area using specialized adhesive. Installation is simple, and sealing performance is good. However, when replacing, residual adhesive must be cleaned, which is relatively cumbersome.

Bolt-fixed sealing strips: These are secured to the screen body using bolts, providing a secure fixation. They are suitable for applications with significant vibration and high sealing requirements, but the installation process is relatively complex.

Classification by material

- Natural rubber (NR) sealing strips: Typically available in standard shapes such as rectangular or O-rings, they offer excellent elasticity and wear resistance, with an operating temperature range of -20°C to 80°C. They are suitable for screening ordinary materials such as sand, gravel, and grain.

- Silicone rubber (SI) sealing strips: Customizable in various shapes and sizes, they offer excellent high-temperature resistance (-60°C to 200°C) and corrosion resistance. They are suitable for industries with high hygiene requirements, such as food and pharmaceuticals, or screening applications involving high-temperature materials.

- EPDM rubber sealing strips: Common shapes include rectangular and U-shaped, with complete size specifications. They are renowned for their excellent aging resistance and weather resistance, suitable for outdoor vibrating screens or environments requiring contact with rainwater or chemical media (such as mining and chemical industries).

- Polyurethane rubber (PU) sealing strips: Customizable thickened rectangular strips and other high-strength specifications are available. Their most prominent feature is excellent wear resistance and high hardness, making them particularly suitable for harsh environments with high wear and strong impact (such as metal ore screening).

Installation and use of sealing strips

Preparation for Sealing Strip Installation

Before installing the sealing strip on the vibrating screen, thoroughly clean the surface of the screen body to remove dust, oil stains, rust, and other debris to avoid affecting the adhesion and sealing performance of the sealing strip. At the same time, check whether the model and specifications of the sealing strip match those of the vibrating screen, and inspect the sealing strip for any damage or deformation. If any issues are found, replace the sealing strip promptly.

Rubber Sealing Strip Installation Steps

Slowly lay the sealing strip along the installation groove of the screen body, ensuring it fits tightly against the groove to prevent twisting or wrinkling. During installation, the sealing strip can be trimmed to fit the length of the installation groove. Ensure the cut edges are smooth to maintain its sealing integrity. For sections requiring splicing, use specialized adhesive or connectors for fixation.

Installation Precautions

Avoid excessive stretching or compression of the sealing strip during installation, as this may impair its elasticity and service life. Ensure the sealing strip is installed correctly and does not deviate from the installation groove, as this may cause sealing failure. After installation, conduct an initial inspection to verify the sealing strip is securely installed and free of loosening or displacement.

Sealing strip specifications compatible with common brands and models of vibrating screens

| Circular Screen | O-ring: Φ8mm–Φ15mm; Rectangular: 15mm×10mm | Seals between screen frame and cover. |

| Linear Screen | U-shaped groove: 20mm(W)×15mm(H); Corrugated: 25mm×12mm | Seals side panels and screen frame. |

| High-Frequency Screen | Corrugated: 30mm×20mm; Custom L-shaped silicone strips | Designed for sealing under high-frequency vibration. |

| Mining Screen | PU rectangular: 25mm×15mm; Thickened EPDM: 30mm×20mm | Wear and impact-resistant. For sealing in heavy-duty mining screens. |

Vibrating Screen Rubber Gasket Diameter Availability (Unit: mm)

| Type | 400 | 500 | 600 | 800 | 1000 | 1200 | 1500 | 1800 | 2000 |

|---|---|---|---|---|---|---|---|---|---|

| U Type | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| V Type | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Small U Type | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Ultrasonic | ✓ | ✗ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

Custom Rubber Sealing Strip for Vibrating Screen

To provide the Rubber Sealing Strip for your vibrating screen, please provide the following customised parameters:

- Material Requirements: Specify rubber type (NR/SI/EPDM/PU, etc.)

- Precise Dimensions and Shape: Cross-section diagram/critical dimensions (including tolerances) and total length.

- Installation Method: Slot/adhesive backing/bolts?

- Operating conditions: Vibration (frequency/amplitude), operating temperature range, environment (medium).

- Material characteristics: Material name, temperature, wear/corrosion/viscosity, etc.

- Special performance requirements: Hardness (Shore A), color, certification (e.g., food-grade).

- Reference samples/old parts: Providing physical samples is the most direct and reliable method (strongly recommended).