What is a vacuum feeder?

In the pharmaceutical industry, material conveying and handling is one of the key links in the production process. Traditional material conveying methods often have problems such as dust contamination, cross contamination, low efficiency, etc. The emergence of vacuum feeder provides an efficient, clean and safe solution for the pharmaceutical industry.

The working principle of vacuum feeder is based on the vacuum negative pressure technology, through the vacuum pump or fan in the closed pipeline system to produce negative pressure, the material from one place and transported to another place. This conveying method completely avoids the contact between the material and the external environment, effectively preventing dust leakage and cross contamination, in line with the strict requirements of the pharmaceutical industry on cleanliness. At the same time, the vacuum feeding machine adopts fully enclosed design, the material in the conveying process does not contact with the outside air, to avoid oxidation, moisture absorption and other problems, to ensure the stability of the quality of the material.

Let’s take a look at the performance of vacuum feeder in the pharmaceutical industry.

Vacuum Feeder in the pharmaceutical industry for various processes

Vacuum Feeder is mainly used in the automated conveying of materials and the sealing of process links, which can effectively guarantee the cleanliness, safety and efficiency of pharmaceutical production. The following are its specific applications and advantages:

| Application Scenario | Key Functions of Vacuum Feeder | Core Keywords |

|---|---|---|

| API (Active Pharmaceutical Ingredient) Transfer | Transfers powder/granular APIs (e.g., antibiotics, vitamins) from storage tanks or bags to mixers, granulators, or tablet presses, eliminating manual handling contamination risks. | Vacuum Feeder, API, Contamination Control |

| Formulation Production | Delivers excipients (e.g., starch, lactose) and active ingredients uniformly to mixing equipment for precise dosing in tablets, capsules, or powders. | Vacuum Feeder, Formulation, Dosing Accuracy |

| Aseptic Production | Transports sterilized raw materials in sterile-designed systems for injectables or biologics, preventing microbial contamination. | Vacuum Feeder, Aseptic, Sterile Transfer |

| Intermediate Transfer | Enables closed transfer of intermediates (e.g., dried granules) between processes to minimize cross-contamination. | Vacuum Feeder, Closed System, Cross-Contamination |

| Waste Recovery | Collects process dust or residues to comply with GMP cleaning standards. | Vacuum Feeder, Dust Control, GMP Compliance |

What is the use of vacuum pump in pharmaceutical industry?

Vacuum pumps in the pharmaceutical industry offer the core advantages of clean compliance, energy efficiency, safety and reliability to meet GMP requirements, reduce the risk of contamination and improve process accuracy.Here are some of the specific applications:

| Application | Function of Vacuum Pump | Key Equipment/Process |

|---|---|---|

| Vacuum Conveying | Transports powders, granules (APIs, excipients) without contamination or manual handling. | Vacuum feeder, mixer, tablet press |

| Drying & Concentration | Removes moisture/solvents in lyophilization, spray drying for drug stability. | Freeze dryer, spray dryer |

| Sterile Filling & Packaging | Creates vacuum or inert gas (N₂) environment for vials/ampoules to ensure sterility. | Vial filling machine, blister packaging |

| Waste & Dust Handling | Collects hazardous dust/VOCs to meet EHS and GMP standards. | Dust collectors, filtration systems |

| Process Support | Provides stable vacuum for distillation, extraction, and chemical reactions. | Reactors, evaporators, solvent recovery |

It is worth mentioning that the application of vacuum feeding machine in the field of aseptic pharmaceuticals is particularly prominent. Aseptic production requires extremely high cleanliness of the environment, and any tiny contamination may lead to unqualified products. The fully enclosed design and dust-free conveying characteristics of the vacuum loader make it an ideal choice for the production of aseptic APIs, sterile powdered injections and other high-end pharmaceuticals. Equipped with aseptic filters and other auxiliary equipment, the vacuum loader can complete the conveying of materials under completely aseptic conditions, ensuring the sterility of the products.

Stainless steel vacuum loaders also excel in environmental protection and energy saving. Traditional mechanical conveying equipment is often high energy consumption, and easy to produce noise and dust pollution. The vacuum feeding machine adopts negative pressure conveying, relatively low energy consumption, low operating noise, and completely avoid the dust leakage, in line with the requirements of the modern pharmaceutical industry on green production. In addition, the vacuum feeding machine has low maintenance costs, simple equipment structure, low failure rate, greatly reducing the production downtime and maintenance costs.

Vacuum Feeder Video Showcase

Regular maintenance and care of vacuum feeder

Regular maintenance is essential to increase the efficient operation and long life of vacuum feeders. Thoroughly clean the equipment after each use, especially the filters and seals to prevent material residue and leakage.

Check the filters for blockage or damage every month and replace them if necessary; wear or aging of seals should also be handled in time. Lubricate moving parts, such as vacuum pumps and motor bearings, every 3-6 months, using lubricants that meet GMP standards.

Calibrate the control system every 6 months to ensure accurate parameters, and check the electrical system to avoid safety hazards. Perform a comprehensive inspection every year and record maintenance logs for easy traceability and auditing.

Through standardized maintenance, vacuum feeders can not only meet GMP requirements, but also improve pharmaceutical production efficiency, reduce failure rates, and make the cleanliness and safety of material transportation. If you need more detailed maintenance methods, please contact us, we have a professional team to serve you.

What are the different feeding systems?

Sanyuantang offers three different types of industrial feeding systems to meet specific material handling needs. These include vacuum feeders, vibratory feeders, and screw conveyor feeders. Here is a detailed description of their features:

Pneumatic Vacuum Feeder: This system uses vacuum pressure to transport materials from one location to another. It is particularly effective for handling fine powders, granules, and other lightweight materials. Vacuum feeders maintain a clean, dust-free environment and are ideal for industries that require a high level of hygiene, such as food processing and pharmaceuticals.

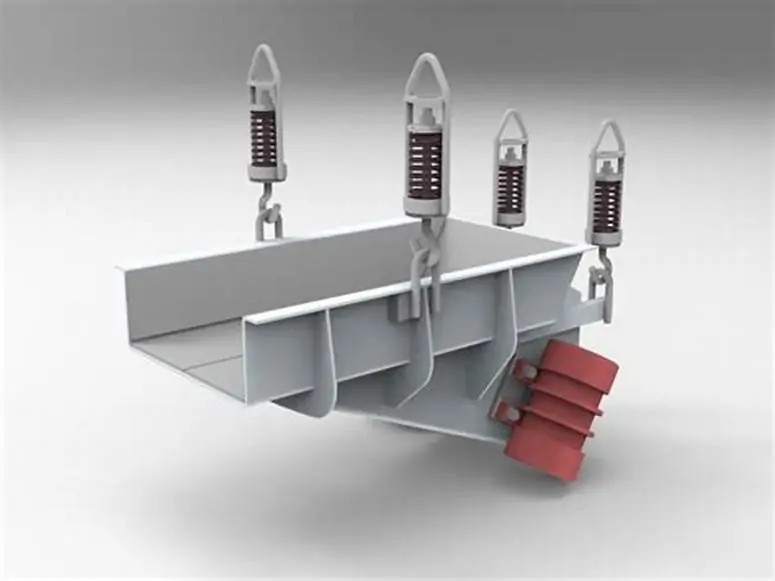

Vibratory Feeder: Vibratory feeders use vibration to move materials along a trough or tube. A variety of materials can be handled, including bulk solids, powders, and even small parts. Vibratory feeders are gentle on materials, minimize degradation, and have a consistent feed rate. They are commonly used in industries such as electronics, automotive, and packaging.

Screw Conveyor Hopper: Uses rotating spiral blades to move materials through a pipe. Screw conveyor feeders are particularly suitable for handling semi-solid materials such as sludge, grain, and other bulk solids. Capable of transporting materials over long distances and handling materials of varying consistencies, it is widely used in the agriculture, wastewater treatment and chemical processing industries.

Partner with us for your pharmaceutical material handling needs

We specialize in high-quality vacuum feeders that are tailored to the unique needs of the pharmaceutical industry.

GMP-compliant designs: Our vacuum feeders meet the highest industry standards.

Customized solutions: We provide systems tailored to your specific requirements.

Expert support: Our team provides installation, training, and ongoing maintenance support.

Contact us today to learn more about our vacuum feeder solutions and how we can help you achieve your production goals. Let’s work together to create a cleaner, more efficient, and more compliant manufacturing environment. By choosing the right vacuum feeder solution, you can transform your pharmaceutical manufacturing process, ensuring efficiency, compliance, and product quality. We look forward to working with you!

Related Articles

- What Is a Vacuum Conveyor? Principles, Applications, and Pneumatic Comparison

- Vacuum Feeding Machine Core Components Analysis

- How to Choose an Right Inclined Screw Conveyor Model?

- How to Select a Suitable Vibrating Screen?

- What is Blender in Pharma Industry

- V Blender Working Principle, Design, Parts, Capacity

- How To Use V Mixer Machine And Precautions