What is the amplitude of a vibrating screen?

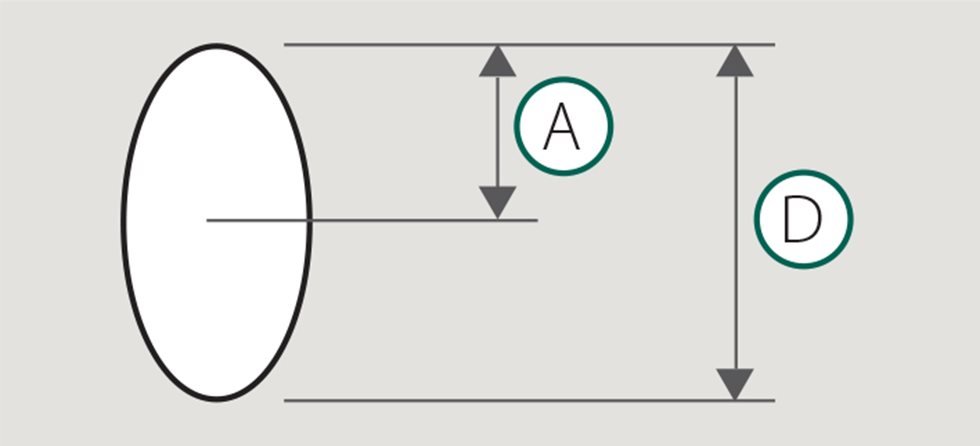

The amplitude of a vibrating screen refers to the maximum distance the vibrating box deviates from its equilibrium position during vibration. This is known as the single amplitude. We commonly refer to single amplitude and peak-to-peak amplitude. Peak-to-peak amplitude is actually a concept relative to single amplitude, meaning the same thing.

Assuming the single amplitude is 5, when the vibrating screen stops working, the peak-to-peak amplitude is 10. Amplitude is an important technical parameter of the vibrating screen, as it affects screening efficiency and production capacity. Let’s now explore how to measure the amplitude of a vibrating screen.

How to measure the amplitude of a vibrating screen

Now that we understand what the amplitude of a vibrating screen is, let’s learn how to measure it.

Static ruler method:

Fix a ruler with millimeter graduations on the side of the stationary screen box. Select a fixed reference point on the vertical plane of the screen box’s motion (i.e., the amplitude direction), and fix a pointer or mark a clear reference point at the reference point. The tip of the pointer should be as close as possible to the ruler (a distance of 1–2 mm is ideal) but should not touch it.

Steps:

- Start the vibrating screen and operate it under normal conditions.

- Observe the range indicated by the pointer tip on the ruler scale.

- The maximum distance the pointer tip swings up and down on the ruler is the peak-to-peak amplitude of the screen box at that point. For example, if the pointer swings between 5mm and 15mm on the scale, the peak-to-peak amplitude is 10mm.

Laser displacement sensor method:

The laser displacement sensor emits a laser beam to the measurement point on the side of the screen box. By measuring the change in the position of the reflected laser, the displacement change of the screen box relative to the sensor is calculated.

Steps:

- Securely mount the laser displacement sensor on a stationary bracket, with the measurement direction aligned with the vibration direction of the screen box.

- Adjust the sensor position and focus to ensure the laser spot is stable on the measurement point on the side of the screen box.

- Start the vibrating screen.

- The sensor outputs displacement signals in real-time to a display or data acquisition system.

- Directly read or record the peak-to-peak amplitude of the displacement signal.

The above are two common methods for measuring the amplitude of a vibrating screen, and we hope they provide some assistance in measuring amplitude. During the use of vibrating screens, we often encounter phenomena where the amplitudes on both sides of the screen are inconsistent. Let’s take a look at the causes of inconsistent amplitude on both sides of the vibrating screen.

Causes of inconsistent amplitude on both sides of the vibrating screen

- Uneven feeding

- When the feed distribution is uneven along the width of the vibrating screen, it can cause the screen to become unbalanced, thereby affecting the amplitude. Therefore, the feed chute should be adjusted to ensure even feeding.

- Loose or Deformed Parts

- When the universal joint or flexible coupling between the two vibrators becomes loose or deformed, it can also affect the amplitude of the vibrating screen. If it is merely loose, tightening it promptly will suffice. If it is deformed, new components must be replaced based on the specific circumstances.

- Vibrator usage exceeding limits

- After continuous use for over 8,000 hours, the bearings of the vibrator will wear out, causing inconsistent amplitude on both sides. Therefore, it is important to monitor the vibrator’s usage status before it reaches its service life and replace it with a new one in a timely manner, rather than waiting until issues arise.

- Spring usage exceeding limits

- The rubber springs supporting the four corners of the vibrating screen have a lifespan of approximately 8,000 to 10,000 hours, while metal springs have a lifespan of approximately 3,000 to 5,000 hours. If damage occurs before the specified time, it may be due to prolonged overloading or inherent quality defects in the springs. To prevent more severe failures, springs should be replaced promptly when they reach the specified usage time or have been overloaded for an extended period. Do not continue using them out of convenience. If the springs have quality issues, choose products from reputable manufacturers with quality guarantees when purchasing replacements.

The above are common issues encountered when the amplitude of the vibrating screen is inconsistent on both sides. Of course, if the above are not the causes of your inconsistent amplitude, you can also contact us. We have professional engineers to help you troubleshoot the issue. Now that we understand the causes, let me teach you how to adjust the amplitude.

How to adjust the amplitude of a vibrating screen?

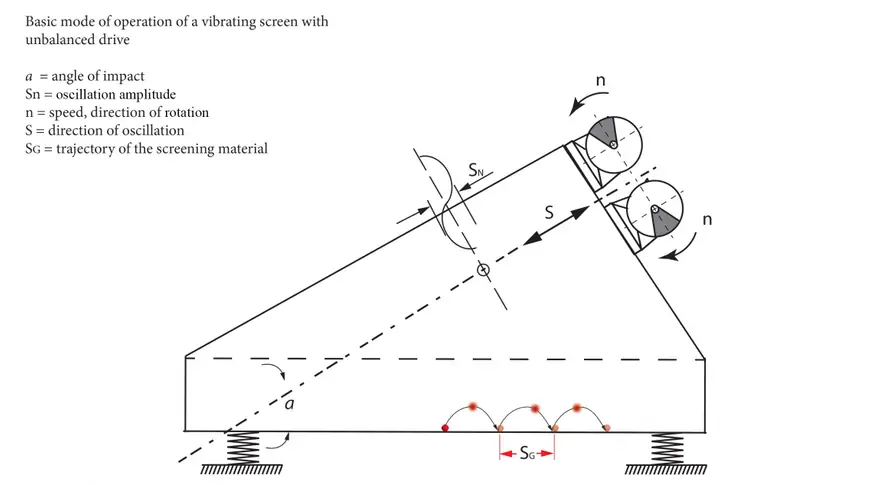

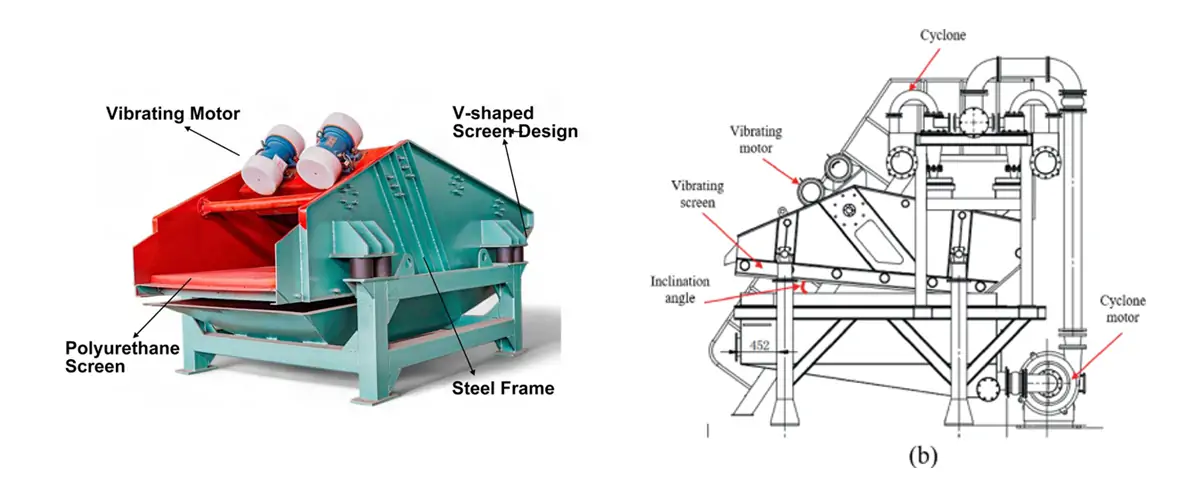

Regarding the vibration source, if a vibrating motor is used, the amplitude can be adjusted by changing the angle of the eccentric clamps at both ends of the motor shaft. A smaller angle increases the excitation force and amplitude, while a larger angle decreases both. If a 6-pole motor is used, the amplitude is typically around 5-8 mm. If an 8-pole motor is used, the amplitude is around 8-12 mm.

If an exciter is used, the protective cover on the exciter can be removed, and the balance weights on the exciter shaft can be rotated to adjust the excitation force generated by the exciter. The balance weights should be positioned at the same percentage location on the exciter, and then the eccentric weights should be secured to adjust the amplitude. The amplitude can also be adjusted by adding or removing the weight of the eccentric weights.

For shaft-eccentric vibrators, the amplitude of the vibrating screen can be adjusted by adding or removing counterweight flywheels or counterweight blocks on the pulley. Alternatively, the amplitude can be regulated by adjusting the frequency converter.

When adjusting the amplitude, it is important to note that the adjustment of the vibrating screen’s amplitude should be based on the characteristics of the vibration source, within the permissible range of the motor. Additionally, the adjustment of the vibration source (vibrator or vibrating motor) on the vibrating screen must be consistent; otherwise, it may cause damage to the equipment. During use, regular lubrication and tightening of bolts should be performed, which will help stabilize the amplitude.

Conclusion:

We have understood the importance of the amplitude of the vibrating screen in actual production. In future production, we should make checking whether the amplitudes on both sides of the vibrating screen equipment are consistent one of the key inspection points to avoid other faults. Additionally, it is necessary to inspect whether the bearings are overheating, whether the bearing temperature exceeds 80°C, whether the rivets or bolts are loose, and whether there are any cracks in the equipment. If any issues are detected, timely measures should be taken to extend the service life of the components and promptly carry out maintenance work to ensure smooth production operations.