Standard test sieve, also known as test sieve machine or analytical sieve, it is widely used in food, building materials, metallurgy, agricultural research, chemical industry, pharmaceuticals and many other fields. Standard test sieve is the laboratory, quality inspection centre, research institutes, as well as all kinds of need for powder, particles and other materials for particle size screening, grading screening of the main equipment. In order to get accurate data and screening accuracy, the use of screening equipment and the use of standard test sieve is also very important. Below we Sanyuantang machinery combined with many years of industry experience, for you to sum up the detailed use of the standard test sieve and the operation of the main points: the following I divided into seven steps to explain the core elements

Table of Contents

- The standard test sieve sieve machine installation

- The choice of standard test sieve screen frame

- Standard test sieve frame installation

- The powder sieve material put

- Standard test sieve sifter parameter setting

- Standard test sieve frame take

- The maintenance of standard test sieve

Operating steps of standard test sieve

1, the standard test sieve sieve machine installation

First of all, we should put the experimental screening machine level stable on the test bench or level ground, at the same time we can also use the level of the instrument for calibration. In this way, the experimental sieving machine can be stable and not shaking when working.

Secondly, we have to make sure that the power supply and earth wire are grounded, which is to ensure the safety of the machine and the safety of the personnel.

Finally, we have to reserve enough working space, especially the vibration part must leave enough space (recommended at least 10-15cm), in this way, the standard test sieve sifter will not contact or collide with the wall, other equipment or objects when working, to avoid damage to the equipment.

2, the choice of standard test sieve screen frame

After we install the machine well, we have to carry out the standard test sieve according to our experiments or work needs.

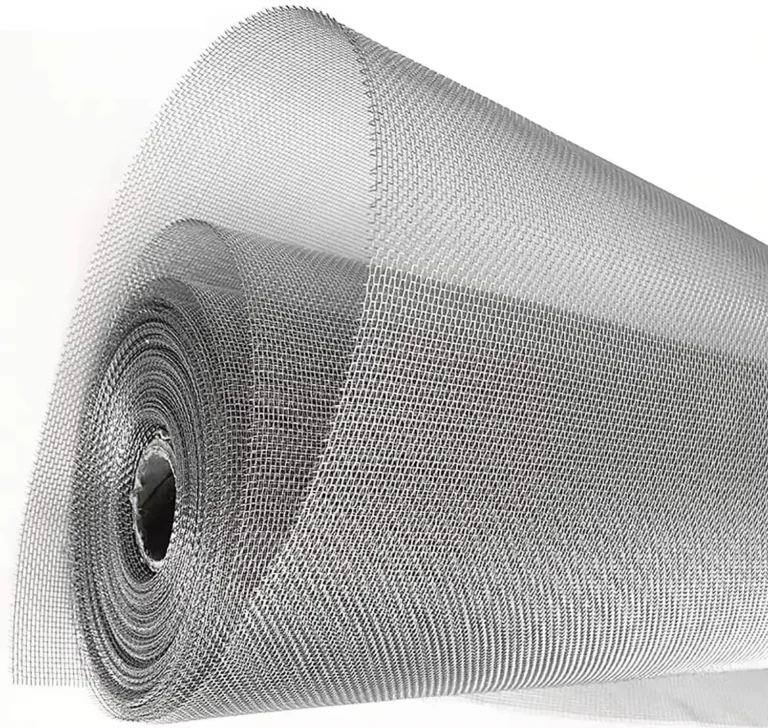

According to the characteristics of the material to be tested (such as particle size range, particle shape, moisture content, viscosity, etc.) in accordance with national standards, industry standards or internal test procedures to select the appropriate specifications of the standard test sieve frame. The standard test sieve frame is the main attention of the screen mesh / aperture, before use, we should carefully check whether the screen is broken, deformation, blocking or corrosion. Whether the edge of the sieve frame is flat, whether the sealing rubber ring is intact.

3, standard test sieve frame installation

standard test sieve frame installation we have to select the standard test sieve sieve frame in accordance with the aperture from small to large, bottom to top stacked in order. Stacked to ensure that the slot or positioning pin of each sieve frame in place accurately.

4, the powder sieve material put

will be tested material poured into the top of the standard test sieve frame. Pouring the amount of material should not be too much, not more than 1/3 to 1/2 of the height of the sieve frame, try to make the material on the screen surface distribution is relatively uniform. Then cover the top layer of the standard test sieve with a lid.

Note that the locking strength around must be consistent, to ensure that all the sieve frame closely fit, no loose gap.

5, standard test sieve sifter parameter setting

Set the sieving time on the timer of the standard test sieve sifter. For easy screening, good fluidity of the material, the time can be slightly shorter; for difficult to screen, sticky or fine powder materials, the time can be appropriately extended. All the settings are correct, the sieve frame is fixed firmly, turn on the power switch, you can start working.

6、Standard test sieve frame take

When the timer reaches the set time, the equipment will stop working automatically. If you need to stop in the middle, please press the stop button. After the equipment stops completely, loosen the lock nut and remove the pressure plate. Then remove the sieve frame from top to bottom to get different materials.

7, the maintenance of standard test sieve

After the operation is completed, turn off the power switch in time and unplug the power supply, and then use a soft brush, special cleaning ball or compressed air to carefully clean the residual material on the sieve mesh to keep the equipment clean.

Conclusion

Sanyuantang Machinery has been ploughing into the field of screening equipment for many years, we provide standard test sieve series products, which strictly follow the national standards, and are made of high-quality materials and precision craftsmanship, at the same time, we provide a variety of specifications for standard test sieve frames, such as woven wire mesh, metal perforated plate and accessories, to meet your diverse particle size screening needs.

If you have any questions about the selection, operation, maintenance or calibration of standard test sieves, please feel free to contact Sanyuantang Machinery!