How to separate a solid from a liquid is a common question in many industries, such as food processing, pharmaceuticals, and chemicals. Solid-liquid separation refers to the process of removing solid particles from a liquid mixture to achieve a clear fluid or to recover valuable solids.

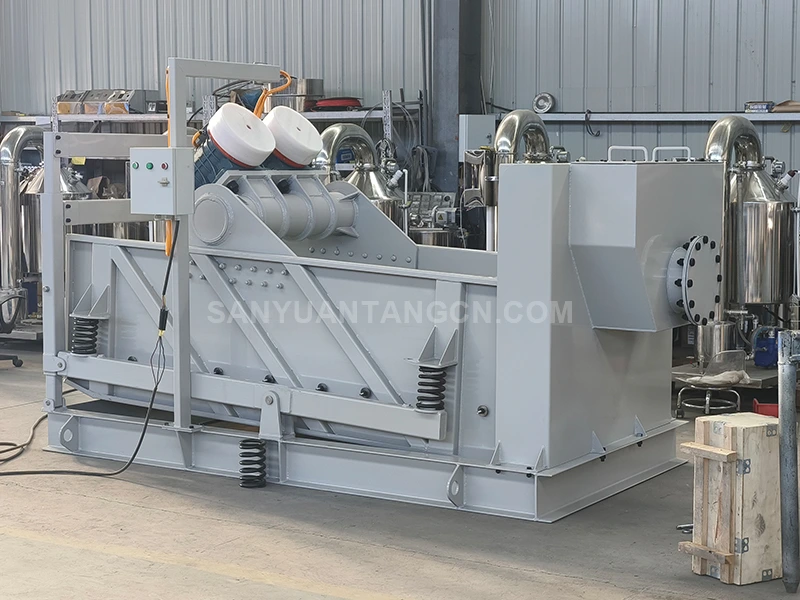

The Sanyuantang 450 Stainless Steel Vibrating Filter Screen provides an efficient, reliable, and hygienic solution for this purpose.

Working Principle of the Vibrating Filter Screen:

The working principle of stainless steel vibrating filter is: the motor drives the heavy hammer to produce excitation force, which drives the screen body to do horizontal, vertical and inclined three-dimensional movement.

This movement makes the material thrown up on the screen mesh, then rotate and spread around from the center of the screen mesh, and finally discharged from the discharge port. During the movement of the screen, fine particles or liquid can pass through the mesh of the screen. By selecting and installing the right screen and its layers, the material can be screened, graded or filtered. The screened and graded materials will be automatically discharged from their respective discharge ports.

How to Use the Filter Screen

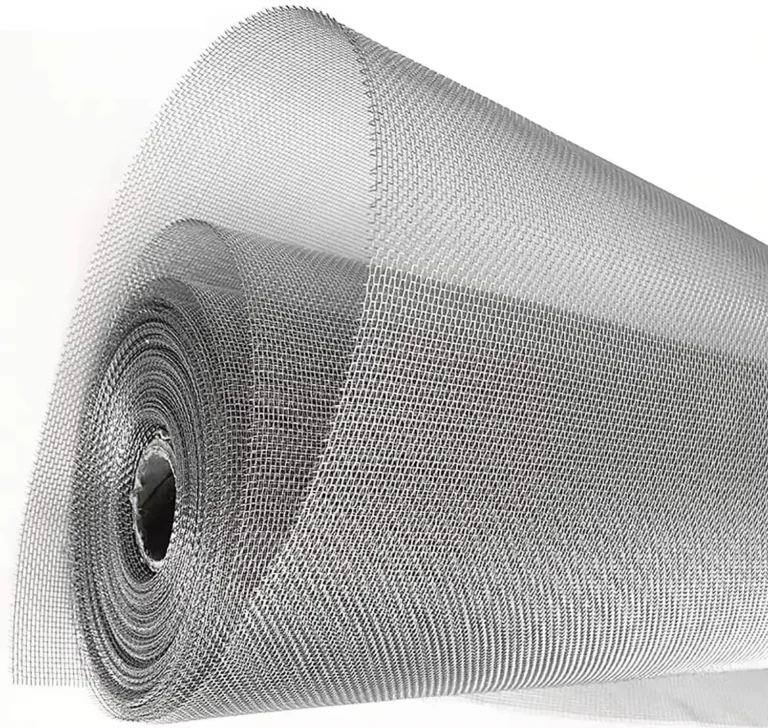

According to the size of different materials we should choose the appropriate filter mesh to realize our solid and liquid separation process, but also should pay attention to the use of filter mesh. There are generally two ways to use the filter screen: one is to pour the mixture directly into the screen plate, let the liquid flow out from the holes of the screen plate, leaving the solid particles; the other is to put the screen plate on the filter funnel, and then pour the mixture into the funnel, let the liquid flow out from the funnel mouth, leaving the solid particles on the screen.

Of course, screens are not suitable for all occasions where it is necessary to separate solids from liquid substances. For fine particles, dispersed suspension, the use of screens is difficult to completely separate, you need to use centrifuges, ultrafiltration and other methods. For solid substances with large particles and high density, it is necessary to use a coarse pore size screen, otherwise it will clog the screen and affect the separation effect.

Advantages of Sanyuangtang 450 Stainless Steel Vibrating Filter Screen

- Efficient Solid-Liquid Separation: Quickly separates mixed substances with high accuracy.

- Durable All-Stainless-Steel Design: Corrosion-resistant and easy to clean, ensuring a long service life.

- Compact and Sealed Structure: With an upper cover design, it prevents material leakage and contamination.

- Flexible Mesh Options: Supports different mesh sizes for various applications.

- Automatic Discharge: Continuous operation improves production efficiency.

Applications in Various Industries

The stainless steel vibrating filter screen is widely used in:

- Food Industry: Filtration of fruit juice, syrup, milk, and beverages.

- Pharmaceutical Industry: Separation of herbal extracts and liquid medicines.

- Chemical Industry: Filtration of coatings, resins, and chemical slurries.

- Environmental Protection: Wastewater treatment and sludge dewatering.

It ensures both product quality and production safety in industrial applications.

Conclusion:

Stainless steel vibrating filter is a simple and effective device to separate a solid from a liquid, which is not only widely used, but also easy to operate and maintain. In actual production, Stainless Steel Vibrating Filter Screen is also widely used in food, pharmaceutical, chemical and other industries to ensure product quality and safety.