The 450 stainless steel vibrating filter screen refers to a single-layer filtering and screening equipment with 450mm diameter, which is usually used to filter, screen, or separate solid particles or liquid substances. It is suitable for the screening range of 0.038 to 3 mm. The equipment has the advantages of low noise, high efficiency, small size, and easy to move, and is an ideal small screening and filtering equipment. According to different needs, the machine body can be made of 304/316 all-stainless steel, or a combination of stainless steel and carbon steel (the base is carbon steel, which is more economical).

- Dimension(L*W*H): 81*74*129 cm

- Capacity: 100 -1200 kg/h

- Application: Fruit juice, vegetable juice, powders

- Screen mesh: 4-400 Mesh

- Voltage: 380V

Price: $450 ~ $980/ Set

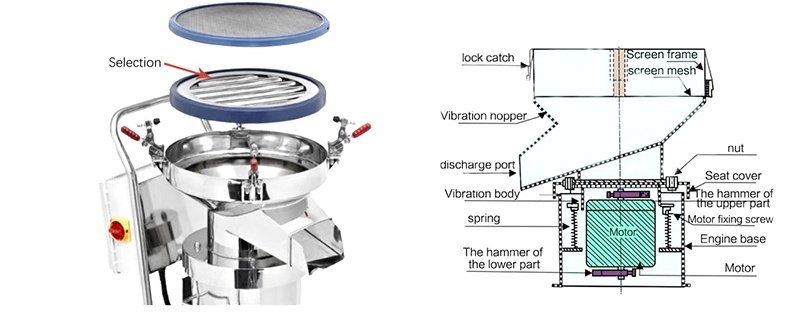

Working Principle

The working principle of the stainless steel vibrating filter is: the motor drives the hammer to generate exciting force, driving the screen body to move horizontally, vertically and tilted in three dimensions.

This movement mode causes the material to be thrown up on the screen, and then rotate and diffuse from the center of the screen to the surroundings, and finally discharged from the discharge port. During the movement of the screen, fine particles or liquids can pass through the mesh of the screen. By selecting and installing the appropriate screen and its number of layers, the material can be screened, graded or filtered. The screened and graded materials will be automatically discharged from their respective discharge ports.

Stainless Steel Vibrating Filter structures:

The 450 vibrating filter screen mainly comprises the machine body, vibration system, lower hopper, screen basket, and electronic control system.

The machine body is a solid support frame installed with vibration, a screen basket, and a lower hopper. The vibration system contains a motor and exciter, which drives the screen basket to vibrate three-dimensionally to screen materials. The lower hopper collects the filtered materials. The screen basket is equipped with screen mesh, optional material, and mesh size, which makes it easy to disassemble and clean. The electronic control system controls the start and stop of the screen machine and speed regulation to ensure safe operation.

Details

Specification

| Model | Diameter | Power | Frequency | Mesh size |

|---|---|---|---|---|

| SY-450 | 400 mm | 0.18 kw | 1460 r/min | 1-300 mesh |

custom design

It supports customized screen and mesh size on demand and provides special design services, such as portable trolley base, open/valve outlet, raised base and tube outlet.

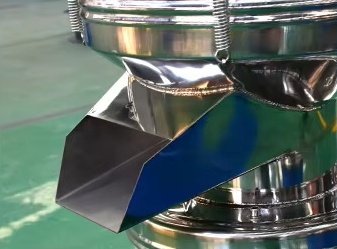

Open/Valve Outlet

Tube Outlet

All Stainless Steel with Upper Cover

Portable Trolley Base

Application

The application scope of the stainless steel vibrating filter is as follows:

Soy milk

Soy milk Juice

Juice Chinese medicine liquid

Chinese medicine liquid Paint

Paint Wastewater

Wastewater Wheat Flour

Wheat Flour Medicine Powder

Medicine Powder Paint Coating

Paint Coating

- In the food industry, the 450 vibrating filter is suitable for processing flour, milk powder, starch, fish meal, rice flour and other powder materials, as well as beverages, juice, sugar, soy sauce, yeast, slurry and other liquid or semi-liquid foods to ensure food quality and taste.

- The chemical industry is also inseparable from the vibrating filter screen, which can effectively screen chemical raw materials such as paint, resin powder, PVC resin powder, citric acid, polyethylene powder, washing powder, etc., to improve production efficiency and product quality.

- In the pharmaceutical industry, the vibrating filter plays an important role. Whether it is Chinese medicine powder, Chinese medicine liquid, or Western medicine powder, Western medicine liquid, it can be finely screened through this equipment to ensure the purity and safety of the medicine.

- In the ceramic abrasive metallurgy industry, the vibrating filter also performs well and is suitable for screening and filtering a variety of materials such as aluminum silver paste, mud, kaolin, quartz sand, alumina, artificial black aluminum, graphite, silicon carbide, spray soil particles, corundum, iron powder, titanium dioxide, electrolytic copper powder, etc. It is especially suitable for filtering ceramic uranium materials.