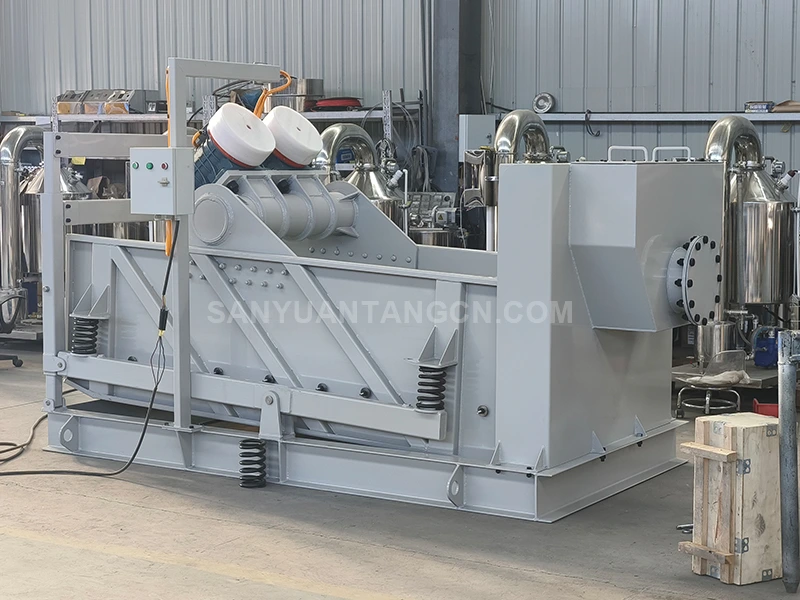

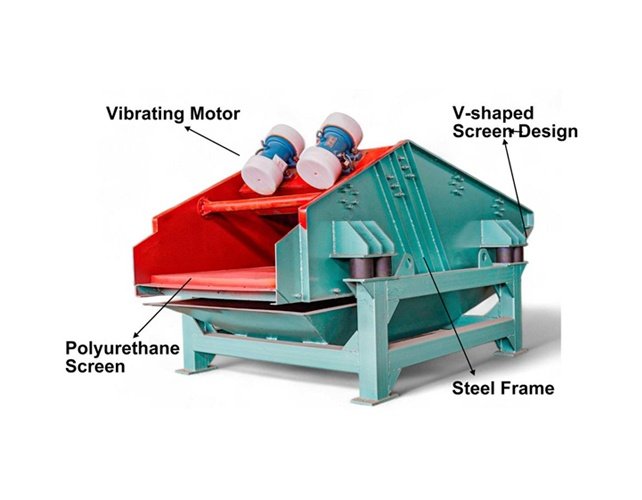

The dewatering vibrating screen is a kind of automatic screening and filtering equipment used for dewatering and solid-liquid separation of large quantities of materials, which is widely used in mining, coal, chemical, environmental protection and other industries. Dewatering vibrating screen usually processing capacity and workload is large, so in the long-term use of the process will inevitably appear a variety of improper operation, wear parts damage and other failure problems occur, today we will analyze five common dewatering vibrating screen failure problems and their solutions.

Dewatering vibrating screen commonly encountered problem solution:

1. the dewatering effect of the dewatering vibrating screen is not ideal

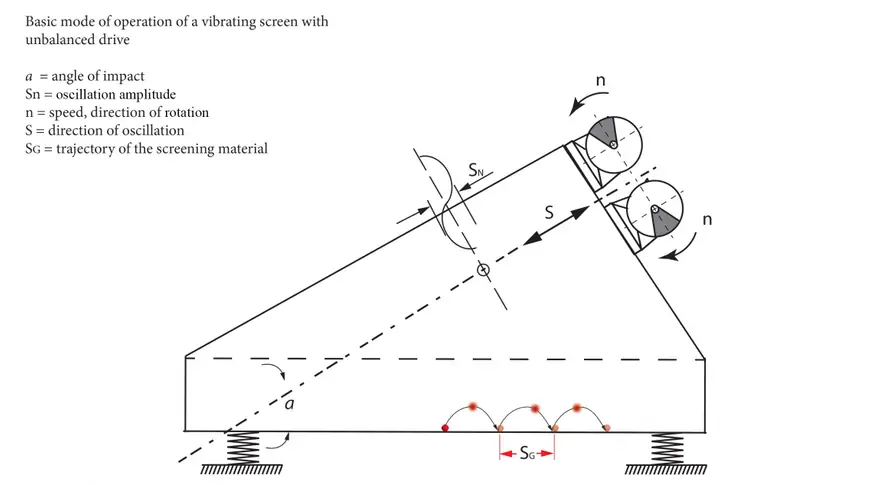

The reasons that usually lead to the poor dehydration effect of the dewatering vibrating screen are: improper operation, mesh blockage, increased fines and moisture in the sieve material, so that the material layer on the screen is too thick, and uneven feeding, etc.. Encountering this situation, we can try to tighten both sides of the dewatering screen mesh, and then carry out a 5-minute reverse rotation, in order to achieve the purpose of enhancing the screening quality.

2. high-frequency dewatering vibrating screen processing capacity is small

When the processing capacity of the dewatering vibrating screen is obviously smaller than expected, there are 3 kinds of adjustments: a. Adjust the position of the eccentric wheel of the dewatering sieve. b. Adjust the feeding method of the vibrating screen. c. Adjust the amplitude of the vibrating screen as well as the inclination angle of the equipment.

Different occasions for the use of vibrating screen capacity and screening efficiency have different technical requirements, so the above methods users need to be flexible according to the specific circumstances of the application.

3. High frequency dewatering vibrating screen amplitude is small or start not up

For the startup problem of the dewatering vibrating screen, Sanyuantang suggests that you can first check whether there are electrical obstacles, motor damage, insufficient voltage and other problems. If the high-frequency dewatering screen amplitude is too small, it will seriously affect the dewatering efficiency and dewatering capacity of the whole machine, you can first check to try to adjust the amplitude of the dewatering screen by adjusting the quality of the eccentric wheel of the motor or selecting a different stiffness of vibrating screen vibration damping springs, and at the same time, check the equipment to see if there is any excessive accumulation of thick material on the screen surface.

4. Material flow abnormality on the screen surface

The reasons are usually these: insufficient rigidity of the screen box, the existence of critical frequency, connecting bolts have been vibration loose, uneven feeding, etc.;.

Find the lateral level of the screen box, from the support of the foot spring support seat or spring itself to find the problem, change the spring or change the size of the support; there may be screen surface mesh damage caused by, as long as the very change screen can be. If the screen box has been due to insufficient rigidity, the horizontal level is not found, will cause the beam fracture, such as still in operation will also make the material flow abnormality.

5. The bearing of the dewatering vibrating screen appears to be hot and broken, and the rotation of the equipment becomes slow.

Dewatering vibrating screen bearing failure often occurs because the quality of the eccentric wheel of the dewatering screen is too large, which leads to the increase of the excitation force and vibrating screen amplitude. Lack of grease in the bearing will directly lead to the heating of the bearing of the dewatering vibrating screen, or the quality of the grease or add too full, the poor quality of the oil so that the bearing is blocked, which will also affect the bearing life of the dewatering vibrating screen. When this fault occurs, you can solve the problem by the following methods:

- Reduce the quality of the eccentric wheel or replace the stiffness of the spring.

- Under the premise of ensuring the strength of the shaft, replace the different types of bearings or change the strength of the bearing seat.

- Reinforce the bottom beam of the dewatering screen to prolong the service life of the dewatering screen.

- Strengthen the maintenance of the bearings to reduce the damage rate of the bearings and increase the rotation speed of the equipment.

Conclusion

The above is about the problems and solutions that may be encountered during the application of the dewatering vibrating screen, if you have other problems or still don’t know how to solve them, please contact Sanyuantang, we will provide you with professional technical guidance and solutions for free.