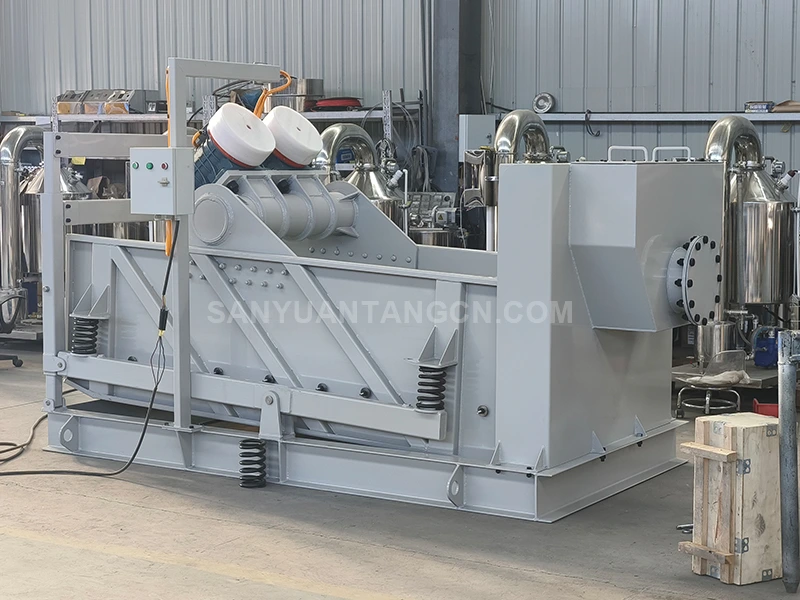

Dewatering vibrating screen is a commonly used dewatering equipment in industry. Its main functions are dehydration, desludging and media removal. It is often used in industrial production such as sand washing in sand and gravel plants, coal slime recovery in coal preparation plants, and dry discharge of tailings in ore preparation plants. Therefore, it is also called sand and gravel dewatering screen, mining dewatering screen, coal slime dewatering screen, tailings dewatering screen, high-frequency dewatering screen, etc.

Now we know what the dewatering vibrating screen is used for, so what is its role in different industries? Let’s take a look at it together.

Industry Applications

Main uses and application industries of the dewatering vibrating screen

| Clean coal, coal slime, and tailings coal | Application Scenario | Function | Common Materials |

| Sand & Aggregates | Sand Washing Production Line | Remove surface moisture from sand, improve product dryness | Manufactured sand, river sand, quartz sand |

| Coal Industry | Coal Slime Recovery in Coal Washery | Reduce moisture content in coal slime, improve resource utilization | Clean coal, coal slime, tailings coal |

| Mineral Processing | Tailings Dry Discharge System | Dewater tailings to meet dry stacking standards | Iron ore tailings, copper ore tailings |

| Environmental Treatment | Industrial Sludge Dewatering | Dewater industrial sludge, reduce sludge volume for easier transport | Municipal sludge, industrial sludge |

| Chemical/Metallurgy | Slurry Concentration Treatment | Increase slurry concentration | Calcium carbonate, slag, metal powder |

| Building Materials | Ceramic Raw Material Processing | Control moisture content and particle size of raw materials | Clay, quartz powder, refractory materials |

Although they are both dewatering equipment, the structure of dewatering screens is different in different application scenarios. For example, the sand and gravel dewatering screens on the water-washed sand production line and the tailings dewatering screens commonly used in the beneficiation plant are different equipment.

Through the above understanding, we know the main role of dewatering vibrating screens in each industry, so what is their working principle?

Working Principle

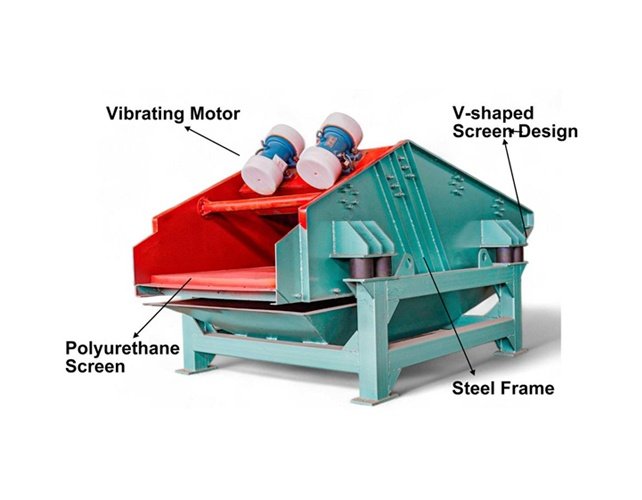

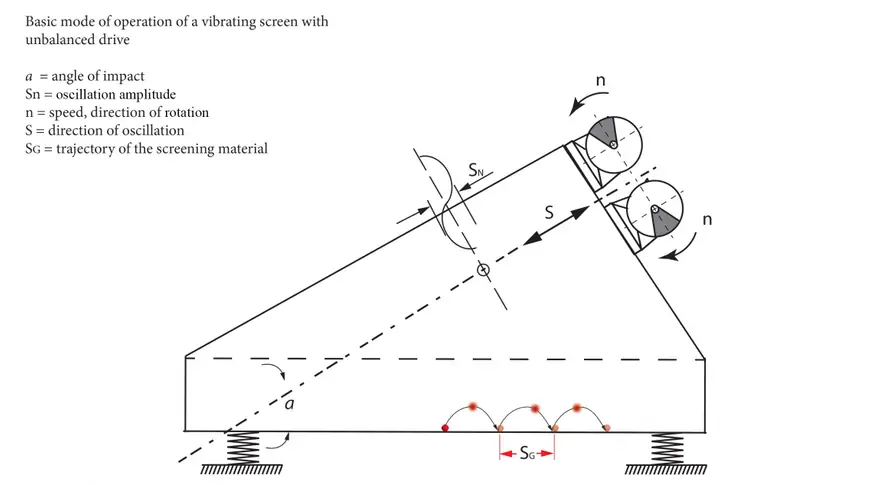

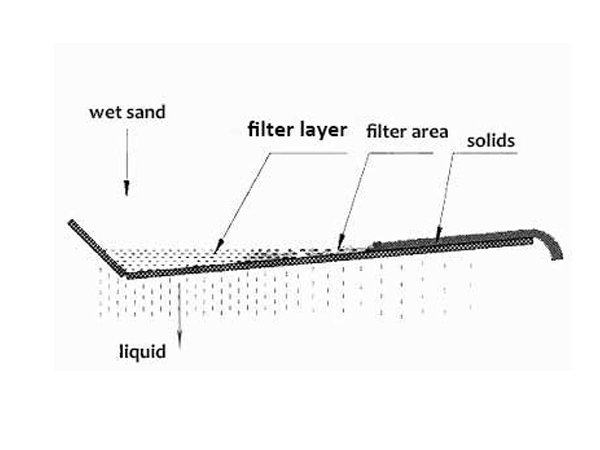

The dewatering vibrating screen separates or dehydrates materials through mechanical vibration. The dewatering vibrating screen is driven by a vibrating motor to convert electrical energy into mechanical energy, driving the screen body to produce high-frequency linear vibration. The screen surface is designed to be inclined, so that the material is continuously thrown up and scattered under the action of vibration, and slides down along the inclined surface. During the vibration process, the water is separated from the material under the action of centrifugal force and discharged through the screen holes. Solid particles are classified according to the difference in particle size. Fine particles smaller than the screen holes pass through the screen with vibration, and coarse particles larger than the screen holes move forward along the screen surface and are discharged from the discharge port.

The drive system usually uses a dual motor synchronous reverse rotation or an exciter structure, which can make the screen body perform a stable linear reciprocating motion. The screen aperture can be customized according to the material characteristics, and the inclination angle can be adjusted. The dewatering vibrating screen completes the particle size classification and dewatering of the material simultaneously through the synergistic effect of vibration ejection, gravity sedimentation, and screen filtration. This is the working principle of the dewatering vibrating screen.

Conclusion

Dewatering vibrating screen has become an indispensable equipment in various industries due to its efficient dewatering performance and wide application. While improving production efficiency and reducing processing costs, it has also contributed to resource recovery and environmental protection.

Sanyuangtang Machinery has 30 years of experience in dewatering vibration screening. We have excellent cases to provide you with all your screening problems.

If you are facing screening problems now, please contact us.