The proper installation methods and precautions for dewatering screens are crucial for the equipment’s normal operation and service life. Through this article, readers should now have a deeper understanding of installing and using dewatering screens. In actual operation, it is imperative to strictly follow relevant procedures to ensure the safe operation and performance of the dewatering screen.

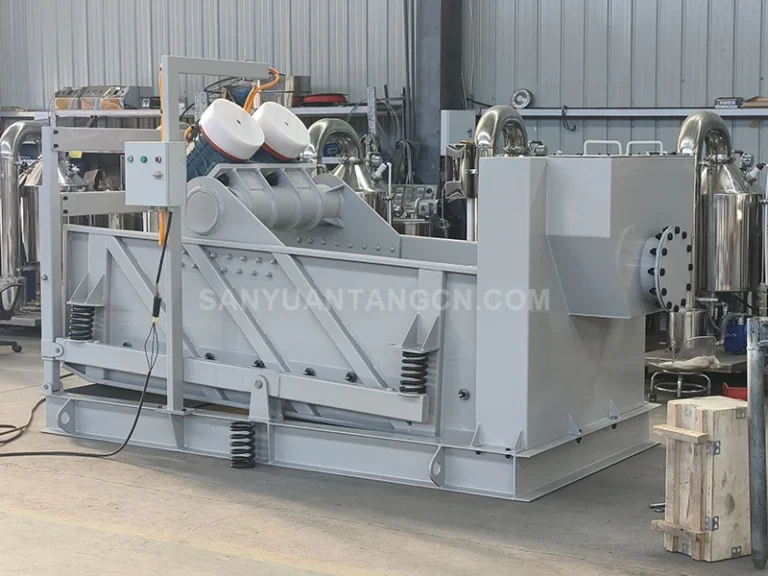

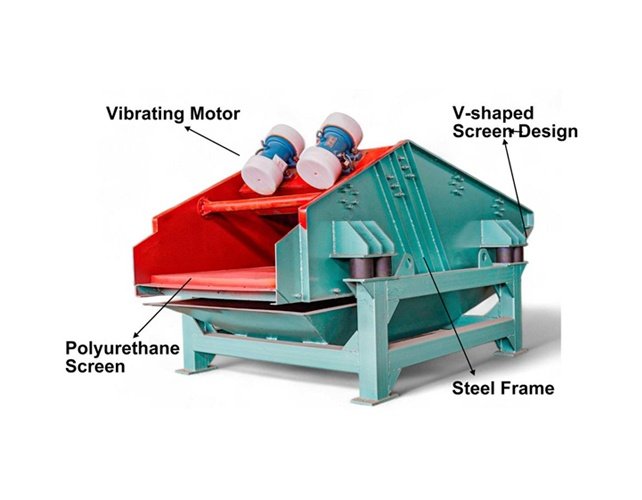

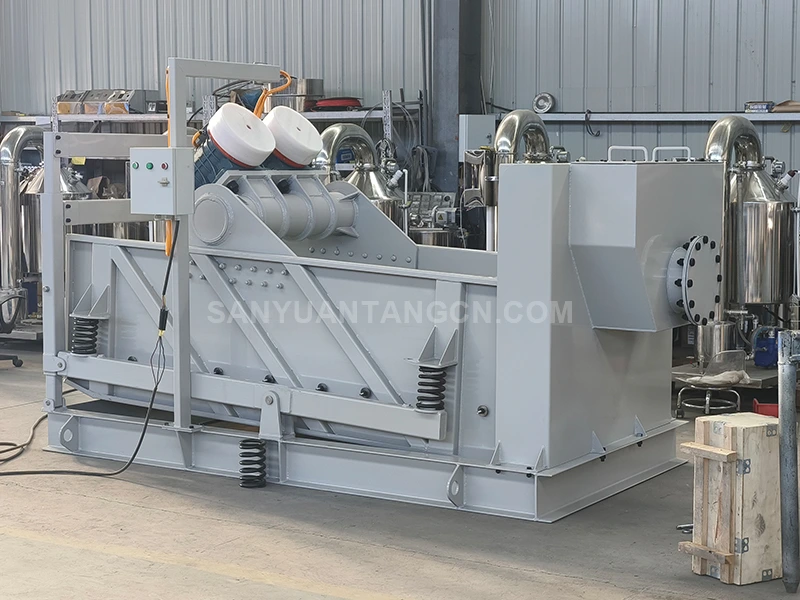

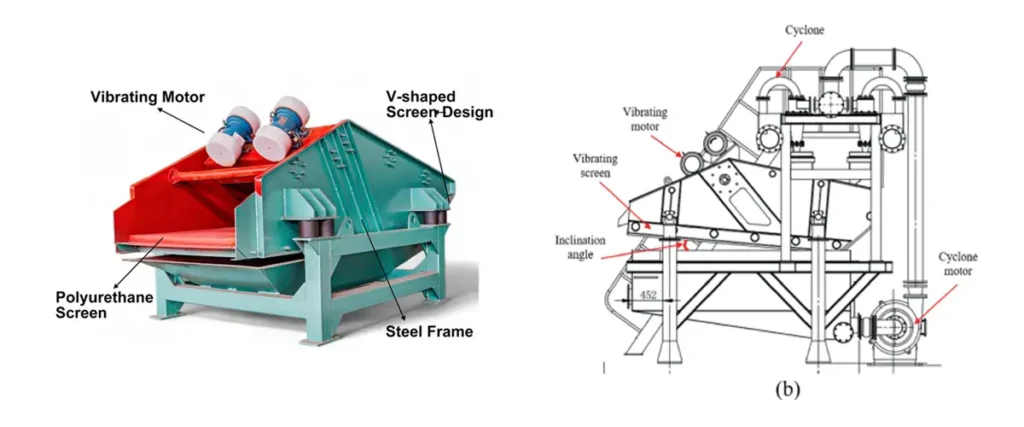

The dewatering screen serves as the primary equipment for separating liquids and solids in industrial production. Its operational stability directly influences its service life and operational costs. However, many users often overlook the importance of proper installation. This oversight can lead to excessive vibration, increased noise, reduced screening efficiency, accelerated component wear, and ultimately shortened equipment lifespan. Therefore, mastering the correct installation steps and safety precautions for dewatering screens is crucial. Today, I will provide a detailed analysis of the entire process from site preparation to post-installation inspection and commissioning, highlighting key considerations to help you avoid common pitfalls and ensure stable equipment operation.

Detailed Installation Steps for Dewatering Screens:

01 Determine Installation Location

Install the dewatering screen on a level, solid foundation to prevent vibration and noise caused by unstable ground. Ensure the location facilitates maintenance and servicing.

02 Install Support Brackets

Select appropriate support brackets based on the screen’s dimensions and weight. These brackets must possess sufficient strength and stability to guarantee safe operation.

03 Connect Feed and Discharge Piping

Connect feed and discharge pipes to the screen according to process requirements. Ensure all connections are securely sealed to prevent leaks and contamination from entering the equipment.

04 Install Electrical Control System

Install the corresponding electrical control system according to the dewatering screen’s electrical requirements. Ensure correct wiring of electrical equipment to guarantee normal operation.

Dewatering Screen Usage Precautions:

01 Safe Operation

Strictly adhere to relevant safety operating procedures during installation and use. Operators must wear proper safety gear. Maintenance or cleaning is strictly prohibited while the equipment is running.

02 Regular Inspection and Maintenance

After prolonged operation, the dewatering screen may experience component wear or loosening. Therefore, regular inspection and maintenance are crucial for ensuring its proper functioning. During inspections, clean internal impurities and blockages, and promptly replace worn parts.

03 Control Feed Rate

Adjust the feed rate according to process requirements to prevent adverse effects from excessive or insufficient material input. Simultaneously, ensure feed uniformity to prevent screen clogging caused by uneven material flow.

04 Proper Lubricant Usage

Lubricants are essential for dewatering screen operation, but excessive or insufficient lubrication can adversely affect performance. Therefore, lubricants must be used appropriately, and the lubrication system’s operational status should be regularly inspected.

Conclusion:

Proper installation and routine maintenance of dewatering screens form the foundation for optimal performance and extended service life. As a professional manufacturer, our dewatering screens not only feature high durability and easy installation but also come with detailed installation manuals and on-site technical support to help you avoid common installation pitfalls.

Whether you require customized installation solutions or encounter questions during maintenance, our team is always available to provide the latest solutions.