What is a wood chip screen? Sanyuantang Machinery will show you how in 30 seconds.

A wood chip screen is a device specifically used for screening and grading wood chips. It uses the principle of vibration screening to screen wood chips according to different particle sizes, and obtains different material particles through screening to meet the needs of different industrial fields for wood chip particles. It is widely used in the processing and screening of materials such as wood chips, sawdust, biomass energy, alternative fuels, and refuse-derived fuel (RDF).

Functions of wood chip screeners

Wood chip screeners are widely used in the process of wood chip processing and processing, and cooperate with chippers to improve working capacity. They have the following functions:

Screening and grading: Screen and grade the original wood chips according to different particle sizes. Through vibration screening, wood chips can be divided into particles of different particle sizes to meet the needs of wood chip particle sizes in different industrial fields.

Used in conjunction with chippers: Separate fine materials and overlong materials from wood chips, or separate mineral components from waste wood for subsequent recycling or heat treatment.

Wood Chip Screen Working Principle

The wood chip screen is powered by a 15KW permanent magnet synchronous motor that drives four vibration sources. These sources, in turn, drive V-belts and synchronous belts to generate an elliptical oscillating motion in the screen box. This motion causes wood chips to “jump” and “slide” across the screen surface. Larger or non-compliant wood chips move along the screen surface toward the discharge outlet, while chips of the correct size pass through the screen openings to the discharge port, achieving grading of wood chips by size. The equipment also allows adjustment of the inclination angle to regulate material movement and grading on the screen surface.

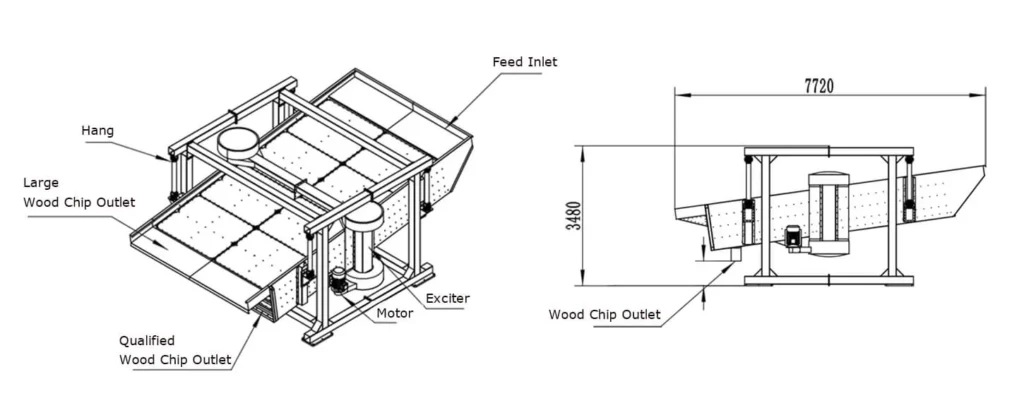

Wood Chip Screen Structure

The wood chip screen adopts a suspended structure, primarily comprising legs, springs, screen box, screen mesh, exciter, and vibration motors. The equipment is easy to disassemble and install, facilitating containerized transportation.

- Vibration Motor: A vibration motor is a motor equipped with built-in eccentric weights. When the motor rotates, the eccentric weights generate centrifugal inertial forces, causing the screen body to produce periodic vibrations.

- Exciter: The exciter imparts specific vibration amplitude and frequency to test objects for vibration and strength, or calibrates vibration testing instruments and sensors.

- Transmission Belt: Drives wood chips through the screen, separating them by particle size during screening.

- Screen Mesh: Grades wood materials by size; target particle size can be adjusted by replacing the screen mesh.

Screen Mesh Replacement Channel

Screen Mesh Replacement Channel Transmission Belt

Transmission Belt Upper Exciter

Upper Exciter Screen Mesh

Screen Mesh Vibration Motor

Vibration Motor Lower Exciter

Lower Exciter

Recommended mesh size of wood chip screen

When choosing the mesh size of the wood chip screen, the value of the mesh size depends on the particle size of the sawdust, production requirements and screening effect requirements.

Coarse screen mesh size: For preliminary screening and removal of larger particles of sawdust, the mesh size of the coarse screen is between 10 mm and 20 mm.

Medium screen mesh size: The mesh size for further screening larger particles of sawdust and separating medium-sized particles is between 5 mm and 10 mm.

Fine screen mesh size: The mesh size of the fine screen for screening fine particles of sawdust is between 2 mm and 5 mm.

Micro-fine screen mesh size: If you need to screen out very fine sawdust particles, you can choose a micro-fine screen mesh size of about 1 mm to 2 mm.

Application scenarios of wood chip screen

Wood processing plant: Sawdust is a by-product of wood processing. The wood chip screen can be used to screen sawdust to achieve wood classification, grading and processing.

Biomass energy production: Wood chips are an important raw material for biomass energy. wood chip screens are used to screen wood chip pellets, wood chip pellet materials, wood chip pellet fuel, etc., and are used in the production and processing of biomass pellets.

Papermaking industry: Wood chips can be used as raw materials for papermaking. wood chip screens can screen wood chips, control the particle size and quality of pulp, and improve the quality of pulp.

Wood board production: wood chip screens play a role in screening wood chip particles and controlling particle size in the production of wood boards (such as particleboard, fiberboard, plywood, etc.).

Wood chip pellet fuel production: wood chip screens select wood chip pellets to remove impurities and ensure the quality and combustion efficiency of wood fuel.

Biomass pellet production: Used to screen particles, control particle size, and improve particle quality and market competitiveness.

Wood chip recycling: wood chip screens screen and recover wood chip pellets, which are reused in production, processing or other purposes.

Advantages of wood chip screen

Humidification treatment: Wood chips with high humidity are easy to adhere to the screen during the screening process, affecting the screening effect. The wood chip screen helps to eliminate the influence of humidity on screening by adjusting parameters such as vibration frequency and vibration amplitude.

Material pretreatment: Pretreatment of wood chips before screening can improve screening efficiency.

Vibration parameter optimization: By adjusting the vibration frequency and amplitude, the material can be fully moved on the screen surface to prevent blockage and improve the screening effect.

Shock absorption design: The vibrating screen may generate noise when working. The wood chip screen usually adopts high-quality vibrators and shock absorption designs to reduce noise and vibration levels and improve operating comfort.

Large processing capacity: The wood chip screen can handle large flows of wood chips to meet the production needs of high output.

Strong adaptability: The wood chip screen is suitable for wood chip particles of different particle sizes, humidity and shapes, and has strong adaptability.

How to Maintain and Service the Wood Chip Screen?

Proper maintenance is crucial for ensuring long-term stable operation of the wood chip screen. Reasonable preventive maintenance not only extends equipment lifespan but also maintains consistent output quality of wood chips.

- Daily Inspection: Observe motor operating status, bearing temperature, and whether the screen body amplitude is normal.

- Screen Surface Cleaning: Regularly remove jammed wood chips or fiber buildup to prevent clogged holes that affect efficiency.

- Weekly Inspection: Check for loose bolts on the motor and all components, inspect rubber springs for damage, and examine the screen surface for tears or enlarged apertures.

- Monthly Inspection: Inspect the screen frame structure and welds for cracks. If cracks are found on crossbeams or side plates, clean the surface first and reinforce with additional plates.

- Annual Maintenance: Completely disassemble the motor for cleaning on the ground. If the rolling shaft shows pitting or fractures, scrap it immediately. Reassemble the motor, ensuring the eccentric weights of the vibrating motor are perfectly aligned.

Conclusion

In general, the wood chip screen plays an important role in the sawdust processing industry. Through screening, the quality of sawdust can be improved, production efficiency can be improved, production costs can be reduced, and the production environment can be improved– Sanyuantang Machinery