The rotary airflow sifter machine is different from ordinary rotary vibrating screen, the screen adopts a cylindrical structure, the material in the barrel by the centrifugal rate and the role of cyclone, so that the material the role of the external force from the screen mesh jet and over, the precision of the screen surface filtration standards of the powder particles discharged through the fine material outlet, the larger particles of materials or impurities through the mesh cylinder wall from the coarse material outlet, to achieve the coarse and fine powder particles.

Details

- Model WQ30-100 rotary airflow sifter screen: Special machine for screening baobab

- Screen material: 304 stainless steel material

- Mesh selection: 350 mesh

- Purpose of screening: grading thickness and fineness

According to the material characteristics of baobab powder, the rotary sifter is suitable for 80-530 mesh of all kinds of powder material screening and grading, its screening efficiency is high, large output, automatic feeding, and discharging, continuous operation, pollution-free, so that it is difficult to carry out high fineness precision screening operations with various vibrating screens in the past. The mesh of baobab powder screening is generally about 325-400 mesh.

Rotary Sifter Machine Features

1. Any granule or powder can be used. Small footprint, stable no vibration, no noise, good sealing performance, no environmental pollution.

2. Can be single-machine or multi-machine matching, three-dimensional multi-layer installation and use, flexible and convenient movement, safe and reliable continuous operation.

3. High screening accuracy, suitable for screening ultrafine powder, small density (light specific gravity), slight humidity, easy to attach sticky powder or electrostatic reaction materials.

4. Long service life of the screen, novel internal structure, durable design of the grid. Easy to change the network, a simple operation. Fiber screen tube or stainless steel screen tube is fixed by ring clamp or strip clamp.

5. The screen is affected by cyclones, with the function of free shaking, automatic cleaning and crushing of block materials, and high screening efficiency.

6. Can be specially designed to meet special needs.

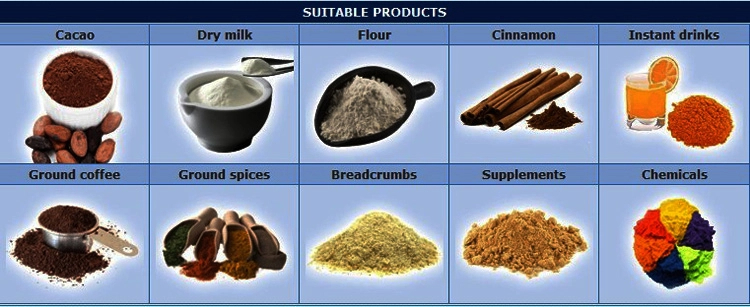

Rotary Sifter Applications

Air flow rotary sifter is suitable for various fine powders that are difficult to screen, such as starch, glucose powder, xylitol, soy protein, peanut protein, vitamin C, sorbitol, Ganoderma lucidum powder, malt powder, coffee powder, bread powder, condiments , food additives, traditional Chinese medicine powder, raw material powder, pharmaceutical intermediates, glass beads, perlite, silicon carbide, silicon powder, activated carbon, epoxy resin, polyethylene powder, fire-fighting agent, zirconium powder, pigments (phthalocyanine, phthalocyanine red , phthalocyanine yellow, yellow lead), high sand ceramic pigments, etc.), magnetic materials, cobalt powder, pyroxene powder, barium sulfate, lithium manganate, zinc borate, fly ash, silica powder, glaze, powder coating, pollen, dehydration Vegetable powder, egg powder, milk powder, soda ash powder, essence, magnesium oxide, magnesium hydroxide, calcium oxide, silicon nitride, aluminum oxide, molybdenum disulfide, cellulose, nanoscale titanium dioxide, PVC resin powder, silica gel powder, Guar gum, calcium fluoride and other powder materials.