Overview

The Korea Starch Processing Factory, a renowned local starch production enterprise, required an advanced cassava sieving machine to meet increasing market demand.

Needs Analysis

The primary raw material for this enterprise is cassava starch. During production, impurities such as coarse fibers and proteins can mix with the starch. To produce high-quality starch products, the factory needed an effective powder vibrating screen to separate these impurities. The customers specified a particle size requirement of 30 mesh for the screened cassava starch and an hourly processing capacity of 4.5 tons.

Cassava Sieving Machine Solutions

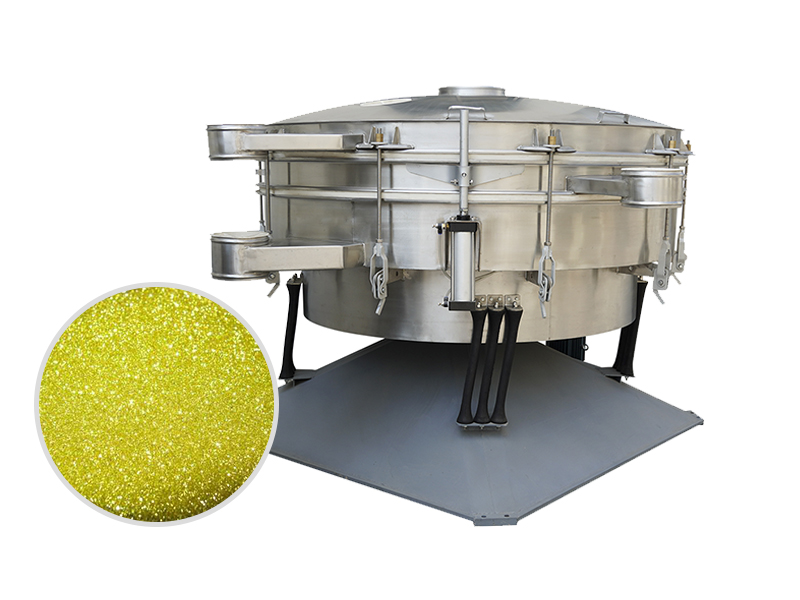

To address the needs of the cassava starch processing plant, we provide a tumbler screening machine solution. This equipment incorporates advanced screening technology and a finely designed sieve mesh, providing high screening efficiency, precision, stable operation, and low noise. It is ideal for screening fine and ultra-fine powders and granular materials, especially those that are difficult to handle.

In practical application, the cassava sieving machine distributes the starch evenly on the sieve mesh through a unique swinging motion, effectively separating impurities. By adjusting the mesh size and screening time, we successfully controlled the particle size of the screened starch to 30 mesh, meeting the customer’s specifications.

Additionally, the cassava sieving machine’s hourly processing capacity reaches 5 tons, exceeding the production requirements of the cassava starch processing plant. The efficient operation of the equipment not only enhances production efficiency but also reduces costs, providing significant economic benefits to the enterprise.

Results

After implementation, the Korea Starch Processing Factory praised the cassava sieving machine’s effectiveness. The screening efficiency and product quality of the starch improved significantly, with effective separation of impurities such as coarse fibers and proteins. The uniform particle size of the screened starch meets customer requirements, and the stability and durability of the tumbler screen have been highly recognized. The equipment operates with low noise and minimal vibration, reducing maintenance costs and operational risks.

Customer Feedback

The head of the enterprise stated, “We have been seeking equipment to improve starch screening efficiency and product quality. The cassava sieving machine provided by your company meets our production needs and brings significant economic benefits. We are very satisfied with your screening equipment and services and look forward to continuing our cooperation in the future.”

Conclusion

The customized cassava sieving machine has successfully addressed the Korea Starch Processing Factory’s needs for high-quality starch production. This case study demonstrates how tailored screening solutions can enhance production efficiency, product quality, and economic benefits for starch processing enterprises.