Overview

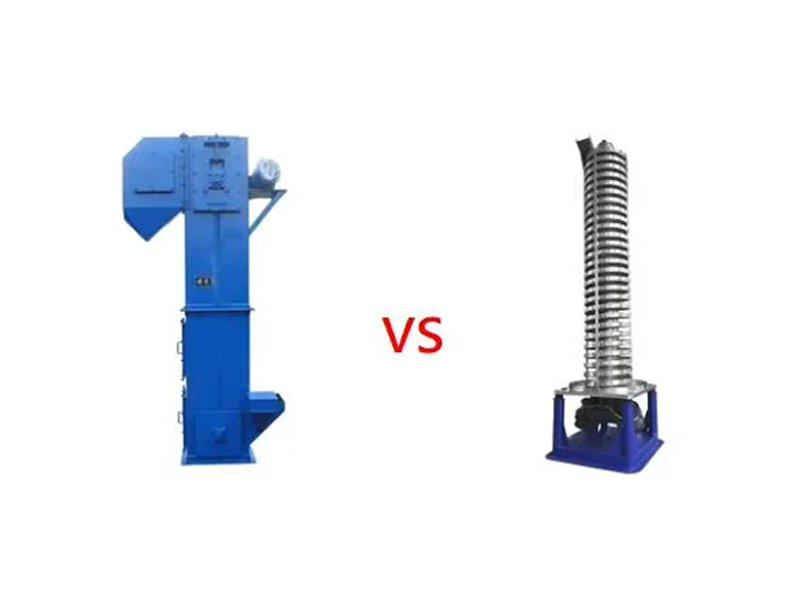

This client is an innovative US-based company engaged in plastic waste recycling and pellet production. They wanted to purchase efficient conveying and lifting equipment that could handle large volumes of granular material to address cold processing and condensation issues. Through Made in China, they discovered the vibrating spiral elevator and sent us an inquiry.

Solution

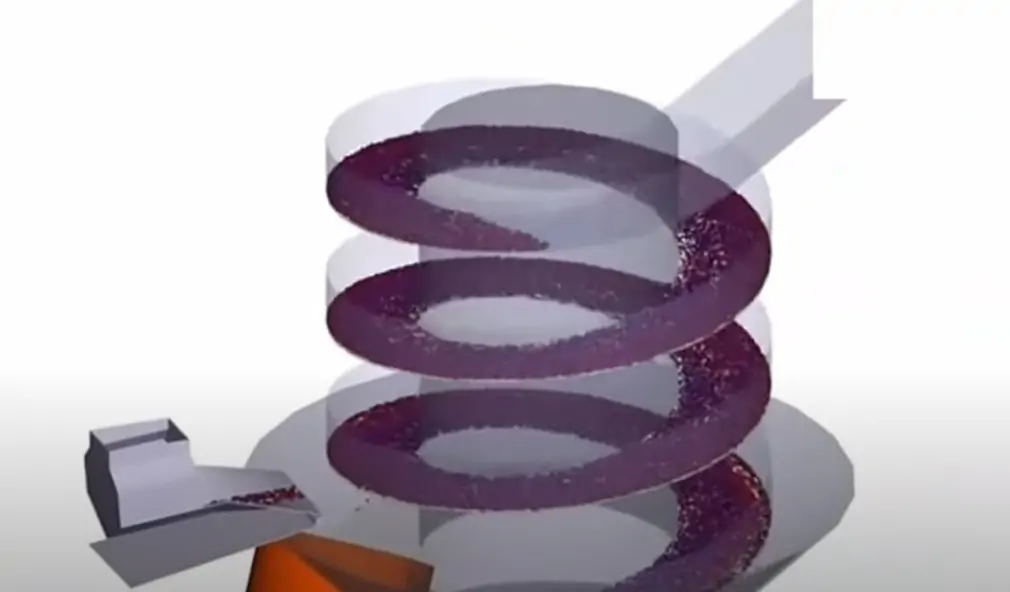

According to the customer’s requirements, the solution we provide is the CZ1000 vibrating screw elevator with a height of 2.5 meters and an output of 2 tons per hour. This screw elevator combines the advantages of vibration technology and a vibrating spiral conveyor, and is specifically designed to handle plastic pellets.

Implementation

The Vibrating Spiral Elevator was installed in the production line, immediately after the pelletizer. This setup allowed the hot plastic pellets to be cooled effectively while being transported vertically. The continuous vibration and spiral movement ensured even cooling and prevent condensation from forming on the pellets.

Results

The implementation of the vibrating spiral elevator led to several notable improvements:

- Enhanced Cooling Efficiency: The vibrating spiral elevator provided consistent and thorough cooling of the plastic pellets, ensuring they reached the desired temperature more quickly.

- Reduced Condensation: The elevator minimized condensation issues by maintaining a stable and controlled cooling process, which previously compromised pellet quality.

- Improved Pellet Quality and Stability: The even and efficient cooling process resulted in higher quality and more stable plastic pellets, meeting the industry standards and client expectations.

- Streamlined Transportation: The vertical design of the vibrating spiral elevator optimized the use of space in the production facility, contributing to a more streamlined and efficient workflow.

- Vibrating spiral elevator equipment features: a small footprint, simple and reasonable structure. Materials can be conveyed upward or downward. Low power consumption and no noise. The closed lifting effectively prevents dust and harmful gases from polluting the working environment.

Conclusion

The vibrating spiral elevator proved to be a highly effective solution for our client in the United States, addressing the critical issues of cold material transportation and condensation in plastic pellet production. By improving the cooling process and maintaining the quality and stability of the pellets, the company enhanced its production efficiency and product standards, reinforcing its position as a leader in the plastic recycling industry.