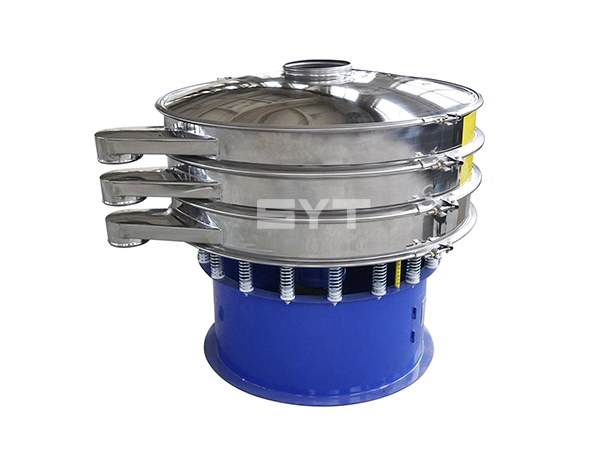

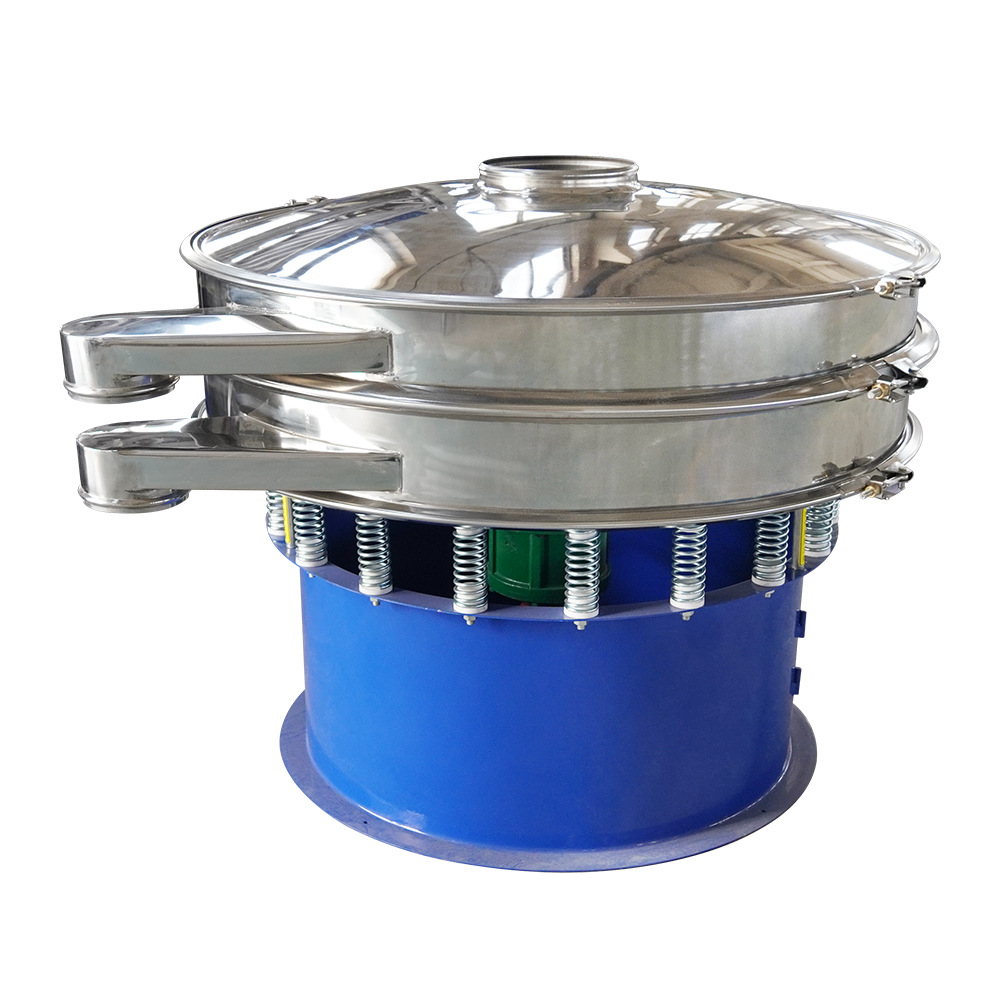

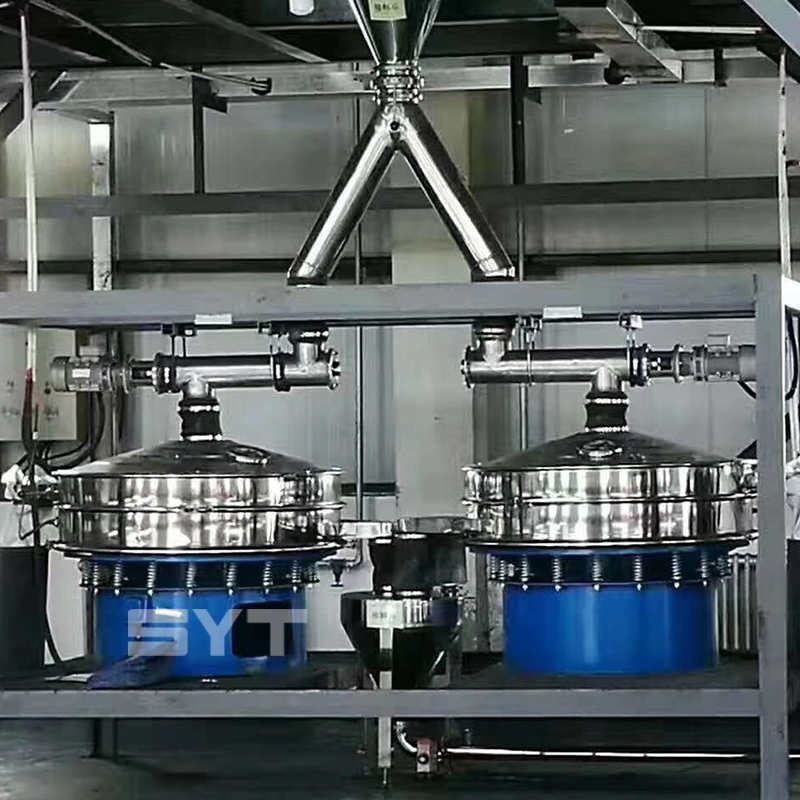

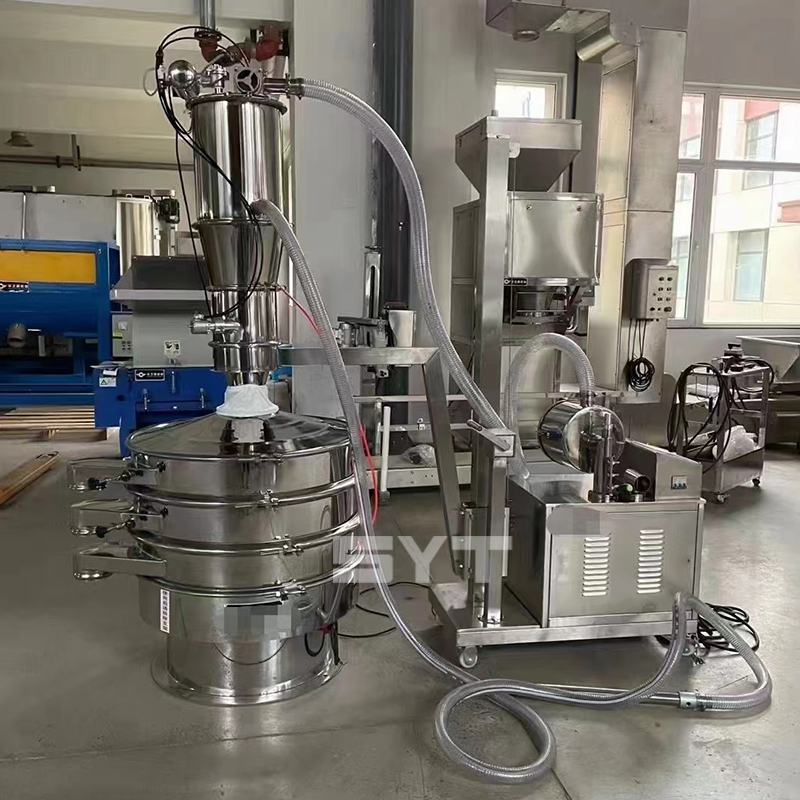

The gyro vibratory sieving machine, also called a vibrating screen separator or vibrating sifter, is a high-precision material screening equipment characterized by low noise and high efficiency. Capable of grading, cleaning, and filtering materials across various conditions, it features a fully enclosed structure ideal for screening and filtering granular, powder, liquid, and other substances.

- Model: SY-600/800/1000/1200/1500/1800 mm

- Material: Stainless Steel 304/316/Carbon Steel

- Mesh Size: 5-500 mesh

- Layers: 1-5 layers

- Motor Power: 0.25-3 kw

- Capacity: 100Kg – 3 Tons/hour

- Service: 5 days delivery/30 days return/support customization/one-year warranty/lifetime service

Price: $799 – $3999 /Set

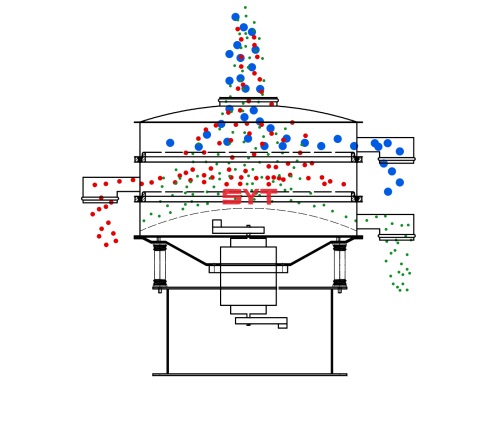

working Principle

The vibratory sieving machine uses an upright motor as the excitation source. Eccentric weights are installed at the upper and lower ends of the motor, which cleverly converts the motor’s rotational motion into a composite motion in three dimensions: horizontal, vertical, and inclined. This composite motion is then transmitted to the screen surface, which drives the material to move in an outward-expanding involute trajectory on the screen surface. Therefore, it is also called a rotary vibrating sieve.

The design of the industrial sieving machine has many advantages. First, the material has a longer running trajectory on its screen surface, which helps to screen the material and improve the screening efficiency fully. Secondly, the utilization rate of the screen surface is high, which reduces the waste of materials during the screening process. In addition, by adjusting the phase angle of the weights at the upper and lower ends of the motor, the movement trajectory of the material on the screen surface can be flexibly adjusted to meet different screening needs.

Vibratory Sieving Machine Structures

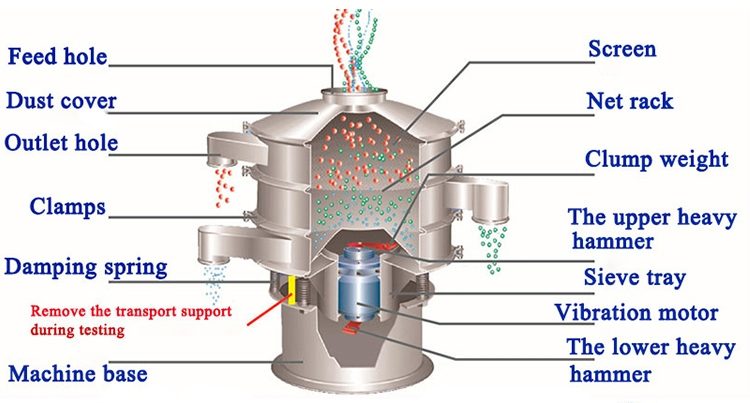

The gyro vibratory sieve separator is mainly composed of the following parts from top to bottom and from outside to inside:

- Dust cover, inlet.

- Screen frame, screen mesh, screen frame, clamp ring, outlet.

- Vibrating motor, vibration transmission body, upper and lower weights.

- Vibration isolation spring, spring washer.

- Base.

Dust Cover with Inlet:

Dust cover: avoid material contamination. Material inlet: The design of the buffer plate makes the material flow into the screen surface evenly, and the material can be inspected through the observation port.

Outlet:

The size of the discharge port can be designed as needed, and the discharge speed through the valve can be adjusted as needed.

Screen Frame:

The middle of the screen can prevent screen cleaning pinballs, reduce damage to the screen by materials, and clean the screen mesh in time.

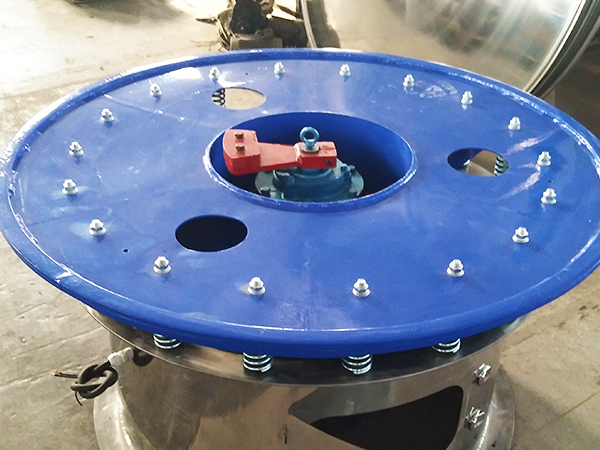

Drive Base:

It is rolled from steel plate and is designed with positioning rings and fixing holes. There is an access door on the cylinder wall to facilitate the adjustment of the upper and lower weights.

Damping Springs:

Buffering and shock absorption prevent the screen frame from being cracked and extend the service life of the screen machine.

Vibrating Motor With Upper and Lower Weights: Change the direction of force to make the material run in three trajectories: horizontal, vertical, and inclined.

Features

- It can screen particles, powders, and mucus within a specific range.

- The screening capacity can reach an amazing 600 mesh or 0.02 mm, while the filtration can capture particles as small as 5 microns.

- It can achieve one to five layers of graded screening and can perform two to six levels of classification or filtering at the same time.

- High efficiency, well-designed and sturdy, easy to replace the screen, simple operation and easy cleaning, ensuring continuous work.

- The direction of the discharge port can be adjusted 360 degrees, and the rotary vibrating screen sieve automatically discharges impurities and coarse materials.

- The mesh has a unique design to extend the life of the screen, and it only takes 3-5 minutes to replace the screen.

- The small size can match the production line operation with limited space and is easy to move.

- The closed structure meets environmental protection requirements.

Application

Application range: battery materials, silicon materials, food industry, pharmaceutical industry, chemical industry, metals, metallurgy and mining, etc.

- Battery industry: graphite, polysilicon, monocrystalline silicon, lithium iron phosphate, ternary materials

- Food industry: sugar powder, starch, salt, oily nut powder, seasoning, candy, coffee beans, tea, rice flour, milk powder, egg powder, soybean, milk, palm oil, soy sauce, jam, juice, food additives, etc.

- Pharmaceutical industry: drugs, Chinese medicine powder, granular pills, micro-pills, etc.

- Chemical industry: coatings, resins, cosmetics, paints, etc.

- Metals: aluminum powder, lead powder, copper powder, ore, alloy powder, welding rod powder, manganese dioxide, electrolytic copper powder, electromagnetic materials, grinding powder, refractory materials, etc.

- Metallurgy and mining: kaolin, lime, alumina, heavy calcium carbonate, quartz sand.

- Environmental protection: waste oil, wastewater, dyeing and finishing wastewater, papermaking, additives, activated carbon, etc.

Flour

Flour Sugar Powder

Sugar Powder Grains

Grains Pills

Pills Medicine Powder

Medicine Powder Rubber Granules

Rubber Granules Paint Coating

Paint Coating Copper Powder

Copper Powder Alloy Powder

Alloy Powder Kaolin

Kaolin Lime Powder

Lime Powder Light Calcium Powder

Light Calcium Powder

Custom Vibratory Sieving Machine

The vibratory sieve allows a throughput of 100 to 5000 kg/hour, depending on the product, mesh size, and feed flow of the machine. It is suitable for screening from 36 microns to 25 mm. It allows the use of 5-layer sieves, which can separate up to 6 products of different specifications and sizes. It is widely used in food, medicine, chemical industry, metallurgy, abrasives, ceramics, and coatings.

One-Layer

Two Layers

Three Layers

Four Layers

Specifications

The model of the round vibratory sieve machine is mainly reflected in the difference in the screen area and the processing capacity of the screen machine. The larger the screen model, the larger the screen area, and the greater the output of the screened material.

| Model | Layer (s) | Granularity (mm) | Sieve Mesh | Effective Diameter (mm) | Power (KW) | Capacity(Kg/h) |

|---|---|---|---|---|---|---|

| SY-XZS400 | 1-3 | <20 | 2-500 mesh | 380 | 0.25 | 100 |

| SY-XZS600 | 1-3 | <20 | 3-500 mesh | 580 | 0.55 | 200 |

| SY-XZS800 | 1-5 | <30 | 3-500 mesh | 780 | 0.75 | 500 |

| SY-XZS1000 | 1-5 | <30 | 3-500 mesh | 970 | 1.1 | 800 |

| SY-XZS1200 | 1-5 | <30 | 3-500 mesh | 1170 | 1.5 | 1200 |

| SY-XZS1500 | 1-5 | <50 | 3-500 mesh | 1470 | 2.2 | 1500 |

| SY-XZS1800 | 1-5 | <50 | 3-500 mesh | 1770 | 3.0 | 2000 |

Material selection for Vibratory Sieving Machine

Vibratory sieving machines are usually made of four materials: all stainless steel, semi-stainless steel for contact materials, carbon steel, and plastic materials.

All Stainless Steel

Semi Stainless Steel Material

Carbon Steel

Anti Corrosion Plastic

1. All stainless steel material

Food and medical-related industries usually use 304 stainless steel for the sanitary vibratory sieve. Stainless steel has better hardness, plate thickness, and wear resistance. It is also strictly polished and polished, making it easier to clean without affecting the quality of the finished product.

2. Semi stainless steel material

The part in contact with the material is made of stainless steel, and the base is made of carbon steel. It is suitable for material screening in the food, pharmaceutical, and chemical industries. Lower price than all stainless steel.

3. Carbon steel material

Carbon steel material does not have high material requirements and is suitable for screening some construction and metallurgical powder particles. The price is much cheaper than other materials.

4. Plastic material

The part in contact with the material is made of polypropylene (PP plastic), which is a screening solution for materials that are corrosive to metals such as carbon steel and stainless steel.

specially customized

In addition to the standard model of the vibratory sieve machine, the vibratory sieve can also be specially customized (non-standard) according to different material screening requirements:

Gate-type:

Gate-type:

The clearance gate design can control the retention and screening time of the material on the screen, ensure the processing accuracy of difficult-to-screen materials (viscous and fine materials), and increase the processing volume. Rim-added:

Rim-added:

The feed inlet is designed to be elevated and protected. The rim-added design can increase the feed volume, prevent material splashing, and observe the screen condition. Add Hopper:

Add Hopper:

Installing a buffer hopper can prevent materials from directly impacting the mesh surface and causing damage to the mesh surface, thereby affecting output and screening quality. Add Scraper:

Add Scraper:

Adding a scraper is mainly used to dissolve, loosen, and filter materials to accelerate the screening speed of materials through the screen and increase the screening output of the rotary vibrating screen.

Our vibratory sieves are complete in models, reasonable in price, made of high-quality materials, professional in manufacturing, and perfect in service. Non-standard customization of industrial vibratory sieves is possible. Please feel free to contact us!