Bucket elevator is a highly efficient equipment for vertical transportation of granular, powdery or lumpy materials, widely used in grain, chemical, building materials, metallurgy and other industries. Correct installation and operation is the key to ensure the efficient operation and prolong the service life of the equipment. This article will provide you with a detailed introduction to the bucket elevator model, structure, installation steps, commissioning methods and operational considerations, to help you better use and maintain the equipment.

Bucket elevator Types and Parts

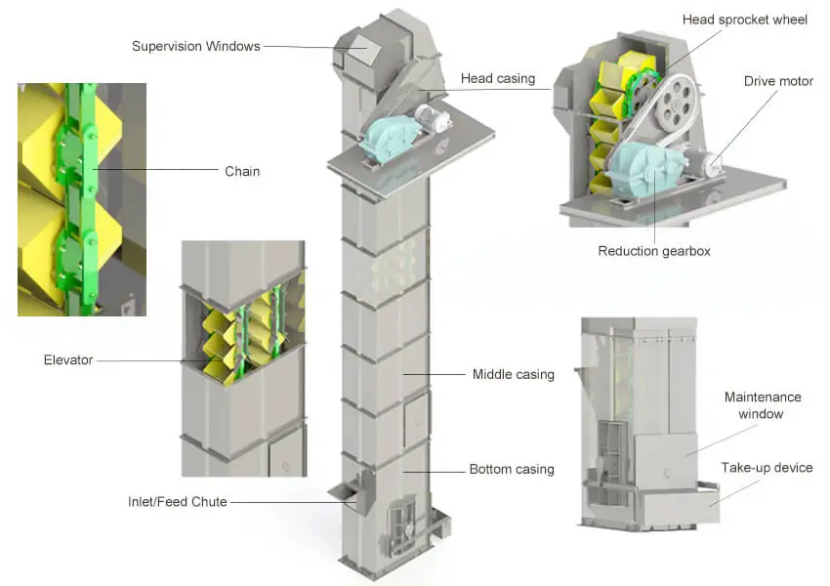

Bucket elevator is mainly divided into three types: ring chain type, plate chain type and belt type according to the different traction parts. Despite the differences in the traction methods of these three types of bucket elevators, their main components are basically the same and usually include the following parts:

- Head: contains the driving device and discharge opening.

- Machine base: contains feeding opening and tensioning device.

- Traction parts: according to different material characteristics can choose chain, plate chain or belt three forms.

- Hopper: used to carry materials, divided into deep hopper and shallow hopper.

- Housing: protects the equipment and prevents material leakage.

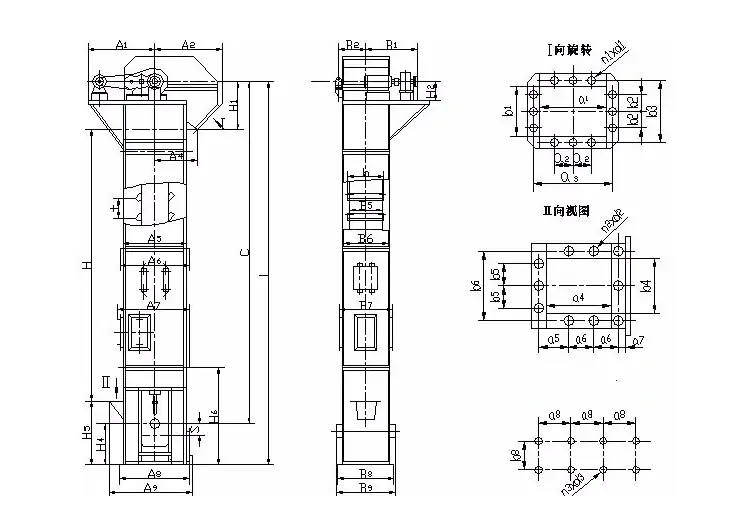

Below is the structural diagram of bucket elevator:

Bucket Elevator Installation Instructions

Preparation before installation

- Check whether all parts of the equipment are complete and make sure there is no damage.

- Prepare installation tools and lifting equipment according to the site conditions.

- Clean up the installation area and make sure the ground is level and free of obstacles.

Installation steps

- Install the machine base: Fix the machine base on the foundation to ensure the levelness and stability.

- Install the head: Lift the head part into place, align it with the seat and bolt it in place.

- Install the traction parts: Install the chain, plate chain or belt to the driving wheel and tensioning wheel with proper tensioning.

- Install the hopper: fix the hopper evenly on the traction parts, make sure the spacing is consistent.

- Install the shell: install the shell in sections to ensure good sealing and prevent material leakage.

- Connect the power supply: connect the power supply according to the electrical drawing and make sure the grounding is good.

Bucket elevator commissioning instructions

- Check before commissioning

- Check whether all the bolts are tight.

- Check whether the traction parts and hopper are installed correctly.

- Check whether the lubrication system is normal.

Commissioning steps

- No-load test run: Start the equipment and observe whether it runs smoothly and whether there is any abnormal noise or vibration.

- Adjust the tension: Adjust the tension of the traction parts according to the running condition to make sure there is no slippage or over-tightening.

- Load test run: gradually add materials, observe the conveying effect, make sure there is no blockage or leakage.

- Adjustment of discharging: adjust the discharging port according to the material characteristics to ensure that the material is discharged smoothly.

Bucket elevator operation instructions

Start operation

- Check whether there are people or obstacles around the equipment.

- Start the power supply and observe the operation status of the equipment.

- Gradually add materials, avoid sudden full load.

Operation Monitoring

- Regularly check the operation status of the equipment, including noise, vibration and temperature.

- Monitor the material conveying effect to make sure there is no blockage or leakage.

- Lubricate moving parts regularly to minimize wear and tear.

Stopping Operation

Stop feeding and wait until the material in the equipment is emptied before stopping.

Turn off the power, clean the surface of the equipment and the surrounding environment.

Record the operation data for subsequent maintenance.

Conclusion

Bucket elevator is an efficient and reliable material conveying equipment, the correct installation, commissioning and operation is the key to long-term stable operation. By following the installation steps, commissioning methods and operating precautions provided in this article, you can maximize equipment performance and extend service life. If you need more technical support or customized solutions, please feel free to contact us – we have 30 years of manufacturing and R&D experience and are committed to providing one-stop service for our customers!

Related Articles

- What is a Bucket Elevator?

- Stainless Steel Bucket Elevator In Food Industry

- Vertical Vibrating Elevator vs Bucket Elevator: How to Choose?

- How Does a Vibrating Spiral Conveyor Work?

- How To Clean The Spiral Conveying Layer When Changing Materials?

- How To Maintain A Vibrating Spiral Elevator Conveyor?

- Vibrating Spiral Elevator For Cooling Plastic Pellets

- Selection Guide for Vibrating Spiral Elevators: Advantages and Disadvantages