A bucket elevator is a mechanical device used to vertically transport bulk materials such as grains, powders, sand, and cement. It consists of a series of buckets attached to a belt, chain, or pulley system, which moves materials from a lower level to a higher level. Bucket elevators are widely used in industries like agriculture, mining, construction, and food processing due to their efficiency and reliability. In this article, we’ll explore the design, working principle, parts, applications, and types of bucket elevators, along with their advantages and pricing.

Bucket Elevator Parts List and Functions

Here are the key components of a bucket elevator and their functions:

Bucket Elevator Belt Splice: Connects the ends of the belt, ensuring smooth operation.

Bucket Elevator Bearings: Support the rotating shafts, reducing friction and wear.

Bucket Elevator Belt Tension: Maintains proper belt tension to prevent slippage.

Bucket Elevator Head: The top section where materials are discharged.

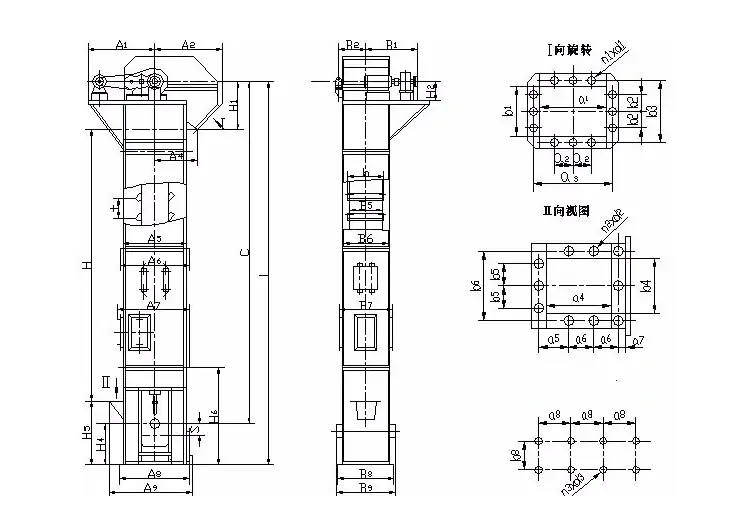

Bucket Elevator Design

Working Principle of Bucket Elevator

The working principle of a bucket elevator is a continuous cycle of material gripping, lifting and unloading. At its core, the material is transported from a low to a high level by means of a hopper fixed to a traction component such as a chain, belt or plate chain. Specifically, the material first enters the base of the hoist through the bottom inlet, and the hopper scoops up the material during operation. With the movement of the traction parts, the hopper rises along a vertical or near-vertical track. When the hopper reaches the top header, the material is thrown out of the hopper due to centrifugal force or gravity and discharged through the discharge opening. The empty hopper then returns to the machine base along the downward track to start a new round of material gripping and lifting.

Advantages and Applications of Bucket Elevators

Advantages

- High efficiency in vertical material transport.

- Compact design, saving floor space.

- Suitable for a wide range of materials.

- Low maintenance and long service life.

Applications

Bucket elevators are widely used in various industries. At Sanyuantang, we specialize in providing bucket elevators for:

- Sand Production Lines: Used in screening and conveying sand.

- Grains: Ideal for rice mills and grain processing plants.

- Powder: Suitable for cement plants and chemical industries.

- Rice Mills: Efficiently transports rice and by-products.

- Cement Plants: Handles bulk materials like clinker and cement.

We also offer complete production line solutions, including crushers, belt conveyors, and screening machines, tailored to your needs.

Bucket Elevator Belt Specifications

| Model | TH160 | TH250 | TH315 | TH400 | TH500 | TH630 | TH800 | TH1000 | TH1250 | ||||||||||

| Hopper type | zh | sh | zh | sh | zh | sh | zh | sh | zh | sh | zh | sh | zh | sh | zh | sh | zh | sh | |

| Conveying capacity, m 3 /h | 19 | 30 | 30 | 48 | 35 | 59 | 58 | 94 | 73 | 118 | 114 | 185 | 150 | 240 | 240 | 360 | 360 | 540 | |

| Hopper | Hopper capacity(l) | 1.2 | 1.9 | 3 | 4.8 | 3.75 | 6 | 5.9 | 9.5 | 9.3 | 15 | 14.6 | 23.6 | 24 | 38 | 38 | 60 | 60 | 95 |

| Hopper distance(mm) | 350 | 450 | 512 | 688 | 936 | 936 | 1001 | ||||||||||||

| Chain | Diameter of round steel x section (mm) | φ12X45 | φ18X64 | φ22X86 | φ24X86 | φ24X86 | φ28X92 | ||||||||||||

| Single chain breaking strength (KN) | ≥170 | ≥320 | ≥480 | ≥560 | ≥560 | ≥660 | |||||||||||||

| Hopper movement Speed (m/s) | 1.3 | 1.2 | 1.4 | 1.5 | 1.6 | 1.6 | 1.6 | ||||||||||||

| Chain sprocket rotation (r/min) | 62.5 | 46.8 | 42.5 | 37.6 | 35.8 | 31.8 | 30.5 | 30.5 | 28 | ||||||||||

| Maximum lump size of material to be conveyed (mm) | 20 | 25 | 35 | 40 | 50 | 60 | 75 | 85 | 100 | ||||||||||

Bucket Elevator Price

| Type | Price Range (USD) |

|---|---|

| Chain Bucket Elevator | $5,000−20,000 |

| Belt Bucket Elevator | $3,000−15,000 |

| Paddle Bucket Elevator | $7,000−25,000 |

For an accurate quote, contact us directly.

Why Choose Us?

As a leading supplier and manufacturer of bucket elevators with over 20 years of experience, Sanyuantang is committed to providing high quality, customized production line solutions. We can provide you with one-stop solutions, including design program, technical guidance, installation guidance, warranty service, etc.

Conclusion

Bucket elevators are essential for vertical material transport in various industries. Whether you need a chain, belt, or plate bucket elevator, Sanyuantang has the expertise and experience to deliver reliable, efficient solutions. Contact us today to learn more about our products and services!

FAQs

Related Articles

- How To Calculate Bucket Elevator Capacity

- 3 Common Types Of Bucket Elevator, Advantages And Disadvantages

- Stainless Steel Bucket Elevator In Food Industry

- Vertical Vibrating Elevator vs Bucket Elevator: How to Choose?

- Dewatering Vibrating Screen Common Problems and Solutions

- Selection Guide for Vibrating Spiral Elevators: Advantages and Disadvantages