Among all vertical conveying solutions, the vibrating spiral elevators is favoured for its versatility: it not only elevates materials but can simultaneously convey, cool, dry, and stabilise their flow. Consequently, it finds extensive application across numerous food, chemical, and metal processing production lines.

Compared to other equipment, their primary advantage lies in their ability to both elevate materials and regulate temperature during conveyance. Below, we explore some of their advantages and disadvantages, along with key considerations for selection.

how does a screw conveyor work

Before we explore its advantages and disadvantages, let us first understand how it works.

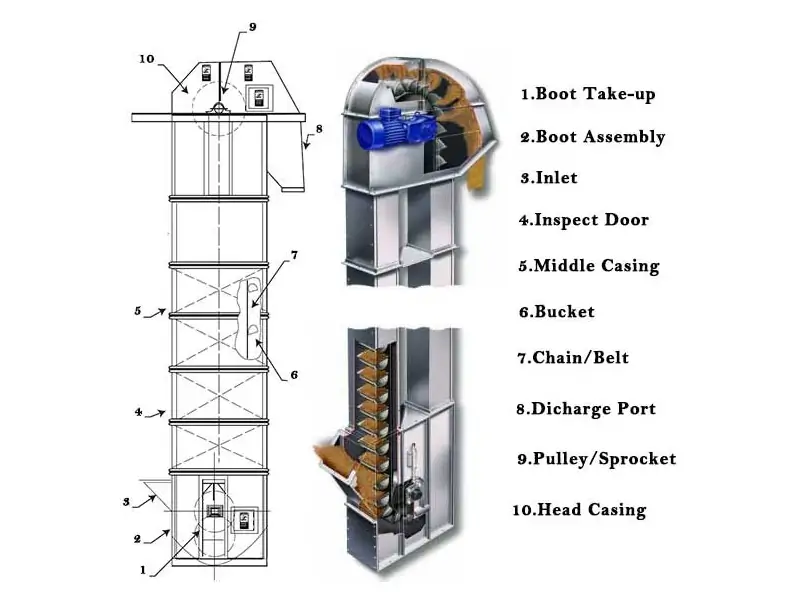

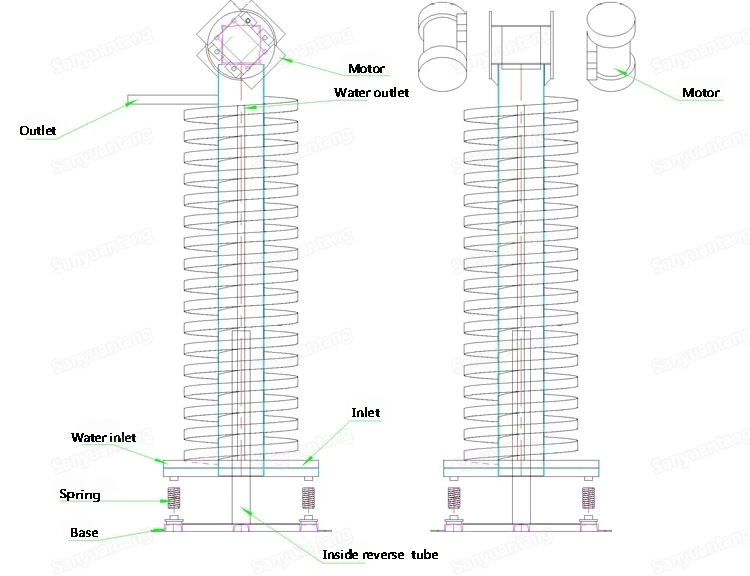

The vibrating motor of the Vibrating spiral elevator is installed in the lower part of the conveying tower, two vibrating motors are symmetrically cross-mounted, the conveying tower consists of the tube body and the spiral conveying groove welded around the tube body, the conveying tower is seated on the vibration-damping device, which consists of the base and vibration isolation spring.

When the vertical spiral conveyor works, according to the principle of self-synchronization of double vibration motors, the vibration motor generates the excitation force, forcing the whole conveying tower to make the space compound vibration of horizontal circular motion and upward vertical motion, and the materials in the spiral groove are subjected to the effect of conveying groove, making the circular motion of throwing at a uniform speed and moving upward along the conveying groove, to complete the conveying of the materials upward (or downward).

Main Advantages of Vibrating Spiral Elevator

- Compact footprint: Vertical design allows seamless integration into confined production areas without requiring overall layout adjustments.

- Smooth conveyance: Vibratory motion ensures continuous upward material progression, eliminating frequent start-stop operations on production lines.

- Preserves material integrity: Powdered and granular materials remain uncompacted during elevation, retaining their original form.

- Synchronised temperature control: Materials naturally accelerate cooling or heating as they unfold along the spiral surface, particularly suited for production lines requiring rapid temperature transitions.

- Simultaneous drying/cooling during elevation: Significantly reduces processing time, especially for products requiring room temperature prior to packaging.

- Low maintenance costs: Eliminates concerns over belt or chain failures, featuring minimal downtime and straightforward cleaning.

- Flexible customisation: Accommodates multiple feed/discharge points, integrates cooling/drying functions, offers explosion-proof designs, and enables material classification processing.

- Broad industry applicability: Suitable for powdered and granular materials across sectors including food, chemicals, metals, and coatings.

Limitations You Should Consider Before Choosing a Spiral Elevator

Even though a vibrating spiral elevator has many strengths, it’s not perfect for every situation.

Here are its main drawbacks:

- Not suitable for extremely high throughput: Its capacity falls below that of bucket elevators or large belt conveyors, rendering it unsuitable for operations requiring exceptionally high output.

- Higher upfront costs: Due to its complex structure and numerous customisable options, the initial investment may be more substantial.

- Limited lifting height: Suitable for short to medium-distance conveyance, but cannot fulfil requirements for extremely high vertical elevation.

- Unsuitable for liquids or viscous materials: Vibratory motion cannot propel highly fluid or easily adhering substances.

- Only applicable to specific material types: Performs well with powdered and granular materials, but not all substances possess these characteristics.

Applications Across Different Industries

The Vibrating Spiral Elevator is ideal for low-viscosity powder or granular materials.

Industries include:

- Food Industry: Sugar powder, Starch, Milk powder, Rice powder, Spices, Seasoning.

- Chemical Industry: PVC resin, Fertilizer, Pigments, Carbonate powder, Cosmetic powders.

- Metallurgy & Metal Processing: Copper powder, Nickel powder, Aluminum powder, Battery materials, Welding powder.

- Special Applications: Cooling & drying spiral conveyor, Explosion-proof spiral elevator for flammable materials, Material classification during conveying, Water-cooled spiral elevators.

PP plastic granules

PP plastic granules Xylitol

Xylitol Chicken Essence

Chicken Essence Chinese medicine granules

Chinese medicine granules Lithium manganate

Lithium manganate

vibrating spiral elevators manufacturers

Sanyuantang Machinery was founded in 1994. Sanyuantang has been focusing on vibrating equipment for more than 30 years.

Our product line includes vibrating screens, rotary screens, linear screens, vertical spiral elevators, bucket elevators, screw feeders, vacuum conveyors, crushers, mixers, and more.

Here’s what makes us a reliable partner:

1. 30+ years of manufacturing experience

Decades of experience mean stable quality and a deep understanding of different material characteristics.

2. Professional customization services

We design customized spiral elevators based on:

- Material type

- Temperature requirements

- Production capacity

- Lifting height

- Plant layout

Whether you need cooling, drying, multi-port feeding, or explosion-proof design, we can build it.

3. Cost-effective logistics service

We provide flexible and economical shipping options, especially for international customers.

4. Long-term after-sales support

Our team provides installation guidance, operation suggestions, parts replacement, and long-term service tracking.

Conclusion

Choose a vibrating spiral elevator that boosts efficiency, stabilises production, and fits your exact needs. With 30+ years of expertise, Sanyuantang delivers reliable, customised solutions for every industry.

Contact us today for a tailored quote and let us help optimise your production line.