Rotary vibrating screens and tumbler screening machines (also known as circular oscillating screens or arc screens) are two highly prevalent types of fine screening equipment. Although they share visual similarities and overlapping applications, fundamental differences exist in their core operating principles, motion trajectories, suitable materials, and screening precision. Understanding these distinctions is crucial for enterprises seeking to enhance efficiency, reduce costs, and ensure product quality when selecting screening equipment.

Tumbler Screen

Tumbler Screen Rotary Vibrating Screen

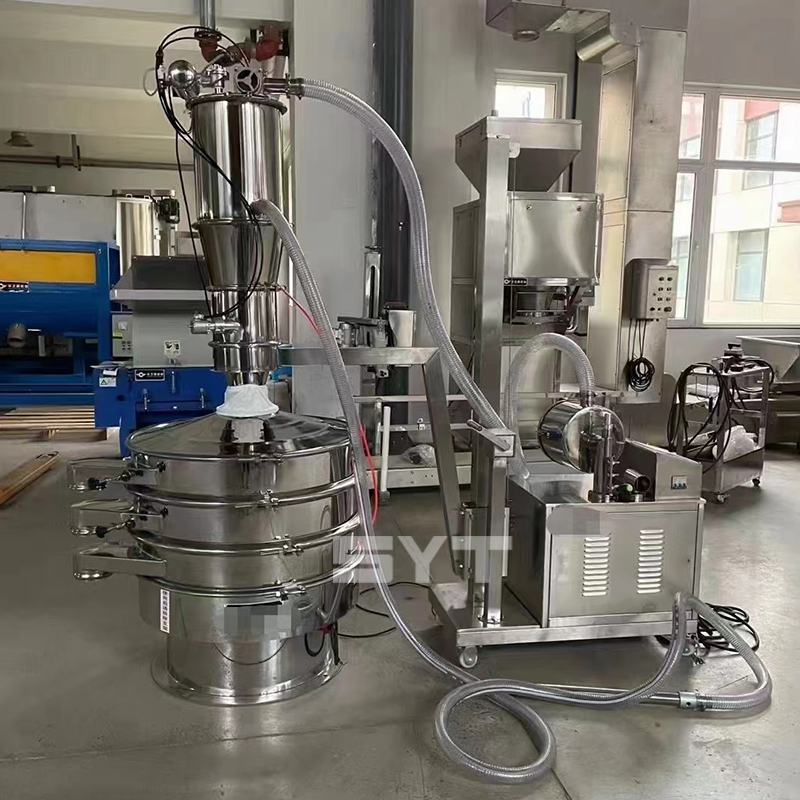

Rotary Vibrating Screen

We shall now systematically compare both devices across dimensions, including operating principles, screening efficacy, suitable materials, operational maintenance, and investment costs. Practical application scenarios will inform our selection recommendations.

The motion trajectory determines two distinct screening methods.

The fundamental difference between the two devices lies in the ‘trajectory of material movement across the screen surface,’ which directly impacts screening precision, throughput capacity, and adaptability to various materials.

Rotary Vibrating Screen: Three-dimensional High-Intensity Vibration

The rotary vibrating screen employs a vertical vibrating motor as its excitation source. Through eccentric weights at both ends of the motor, rotational motion is converted into three-dimensional vibration encompassing horizontal, vertical, and inclined planes.

Advantages:

- Material exhibits predominantly vertical bouncing motion on the screen surface

- Rapid screening speed but intense vibratory force

- Suitable for rapid classification of common powders and slurries

Due to vigorous vibration, elongated, fragile, lightweight, or irregularly shaped materials may produce fines or suffer mis-screening during processing.

Tumbler Screening Machine: Manual-like Flexible Screening

The tumbler screening machine employs an elliptical motion trajectory with slight vertical oscillation. Material disperses uniformly from the centre towards the periphery, progressing axially in a spiral pattern.

Advantages:

- Fully emulates manual screening methods

- Extended residence time of the material on the screen

- Gentle motion that does not damage the material structure

- High screening precision with pronounced stratification effect

Therefore particularly suitable for industries requiring high shape integrity, such as tea, monosodium glutamate, chicken essence, seasonings, and pharmaceutical raw materials.

Screening Performance Comparison: Precision vs Speed

| Item | Rotary Vibrating Screen | Tumbler Screening Machine |

|---|---|---|

| Screening Accuracy | Medium (typically 90–95%) | Very High (up to 99%) |

| Processing Speed | High | Medium to High |

| Material Retention Time | Short | Long |

| Suitable Particle Types | Standard powders, slurries | Long-shaped, fragile, lightweight, and difficult materials |

Conclusion:

Rotary vibrating screens emphasize efficiency and versatility, while tumbler screening machines prioritize precision and gentle processing.

Structural & Operational Comparison: Maintenance Difficulty and Cost Impact

| Feature Category | Rotary Vibrating Screen | Tumbler Screening Machine |

|---|---|---|

| Structure | Simple structure | Longer machine lifespan |

| Screen Replacement | Very fast (3–5 minutes) | Production can restart within 10 minutes after replacement |

| Size & Cost | Compact size, lower cost | Higher durability and longer screen life |

| Sealing | Fully sealed design for food & pharma | Multiple screen-cleaning options (ultrasonic, bouncing balls, etc.) |

| Material Protection | Lower, prone to breakage for fragile materials | Strong material protection during screening |

| Maintenance | Low maintenance cost, low installation requirements | Ideal for difficult materials and high screen wear |

Note:

For difficult materials or high screen consumption, the Tumbler Screening Machine can be more cost-effective in the long run.

Selection Recommendations: Choose Based on Industry & Material Characteristics

When Efficiency & Cost-Effectiveness Matter — Choose Rotary Vibrating Screen

| Category | Details |

|---|---|

| Suitable Industries | Chemical powders, food powders, metal powders, agricultural by-products, slurry filtration |

| Ideal Application Goals | Fast screening, standard powder classification, continuous production lines, medium accuracy requirements |

When Precision & Material Protection Matter — Choose Tumbler Screening Machine

| Category | Details |

|---|---|

| Suitable Industries | Tea leaves, herbal materials, spices & seasonings, food granules, pharmaceutical industry, fragile materials, difficult or high-precision screening fields |

| Ideal Application Goals | Ultra-high precision screening (up to 99%), material protection (zero breakage), screening of long-shaped or lightweight materials, materials with large density differences or special bulk density |

How to choose quickly?

If you want speed and cost-efficiency → Choose Rotary Vibrating Screen

This option is ideal if your priorities are:

- Faster processing speed

- Lower equipment and operating cost

- A versatile screening solution for most standard powders

- Reliable performance for chemical, food, metal powder, and slurry applications

- Medium-level accuracy (90–95%)

- Compact design with easy installation and maintenance

In short: If you want efficiency, versatility, and lower cost — choose Rotary Vibrating Screen.

If you want precision and product protection → Choose Tumbler Screening Machine

This option is ideal if your priorities are:

- Ultra-high accuracy (up to 99%)

- Gentle, human-like tumbling motion

- Screening fragile materials such as tea leaves, herbs, spices, and food granules

- Handling long, lightweight, sticky, or hard-to-screen materials

- Achieving high-purity, premium-grade powder separation

- Reducing mis-screening and material damage

In short: If you want precision, material protection, and premium quality — choose Tumbler Screening Machine.

Conclusion:

Through the above comparison, I trust you are now able to accurately distinguish between rotary vibrating screens and tumbler screening machines.

Should you currently be facing difficulties in selecting the appropriate equipment, we invite you to contact us immediately. Our specialist team will provide you with bespoke solutions tailored to your requirements. Contact us today.