Project Overview

Recently, we received a request from a Mexican customer for a customized vibrating spiral elevator for conveying activated carbon materials containing phosphoric acid (H₃PO₄), which is a key conveyor in the production process and requires high corrosion resistance and structural stability.

Project challenges

Highly corrosive material: The activated carbon conveyed by the customer contains phosphoric acid, which is highly corrosive, and conventional 304 stainless steel is difficult to meet the demand for long-term stable operation.

Structural design constraints: Initially, the customer wanted to install the drive motor at the top of the hoist. However, considering that the total height of the equipment required by the customer is nearly 9000mm, if the motor is located at the top, the overall center of gravity is too high, and there will be structural instability and operational risks.

Solution

In view of the material characteristics, we suggested upgrading the main material of the equipment to 316L stainless steel. This material is better than 304 stainless steel in terms of corrosion resistance, especially suitable for conveying materials containing phosphoric acid or other strong corrosive components, which can significantly extend the service life of the equipment and reduce the frequency of maintenance.

In terms of structural design, after professional calculation and evaluation, we suggest to change the motor installation position to the bottom of the equipment. This design can optimize the distribution of the overall center of gravity, and improve the stability and safety of the equipment in overhead operation.

Throughout the project, we maintained close communication with the customer, confirming the design drawings and technical parameters to ensure that the Vibrating Spiral Elevator customized solution fully meets the customer’s site conditions.

Result

In the end, the customer adopted our suggestions, confirmed the use of 316L stainless steel and motor bottom mounted structure, and successfully placed an order for 3 sets of vibrating spiral elevators. 3 sets of vertical elevators have been completed, and passed the pre-factory operation test, and will be shipped to Mexico soon. We will continue to follow up the feedback from our customers and look forward to the long-term cooperation between us and our Mexican customers.

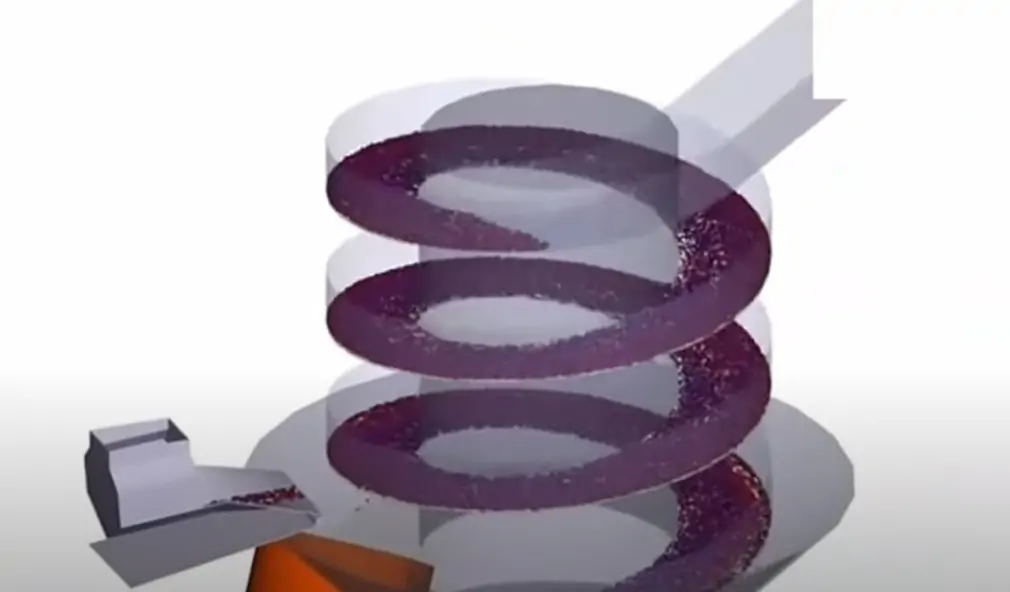

The video below is a pre-factory test. Please click to view the details.