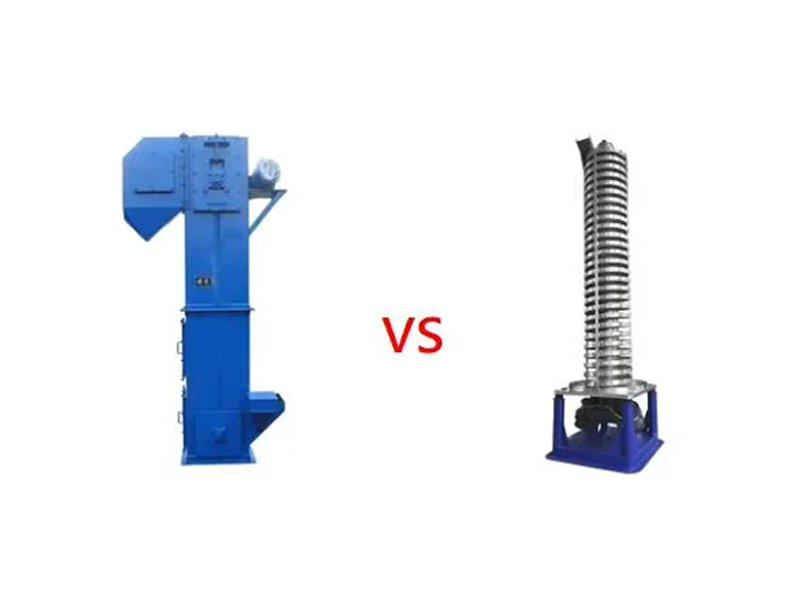

Traditional high-temperature foundry sand cooling usually uses large cooling drums, which are effective but occupy a large area and have high economic costs. In comparison, the cooling spiral lift conveyor produced by Sanyuantang is more economical and efficient. The cooling and lifting solution first uses a vibrating screening device to grade and filter the foundry sand, and then conveys the materials that meet the requirements to the vertical elevator to complete the cooling and convey to the next processing procedure.

Introduction of the cooling and lifting solution:

- Applicable materials: foundry sand, pearl sand, quartz sand.

- Cooling capacity: the inlet temperature of foundry sand is 150-250℃, some materials can be as high as 300℃, and the discharge temperature can be reduced to 50-65℃.

- Single set conveying capacity: 0.5-2m³/h.

- Equipment noise: The noise is less than 80 decibels at 1 meter away from the equipment.

Production line configuration and working principle

The main configuration of high temperature casting sand cooling elevating and conveying production line includes sand screening machine, horizontal double-cooling conveyor, cooling spiral lift convey, and other equipment.

Working principle

- Screening: First, the high-temperature foundry sand is screened by the foundry sand vibrating screen to remove impurities and unqualified particles.

- Cooling: The qualified materials after screening enter the horizontal double cooling conveyor or similar cooling equipment. These equipment usually use cooling water or other cooling media to reduce the temperature of the sand.

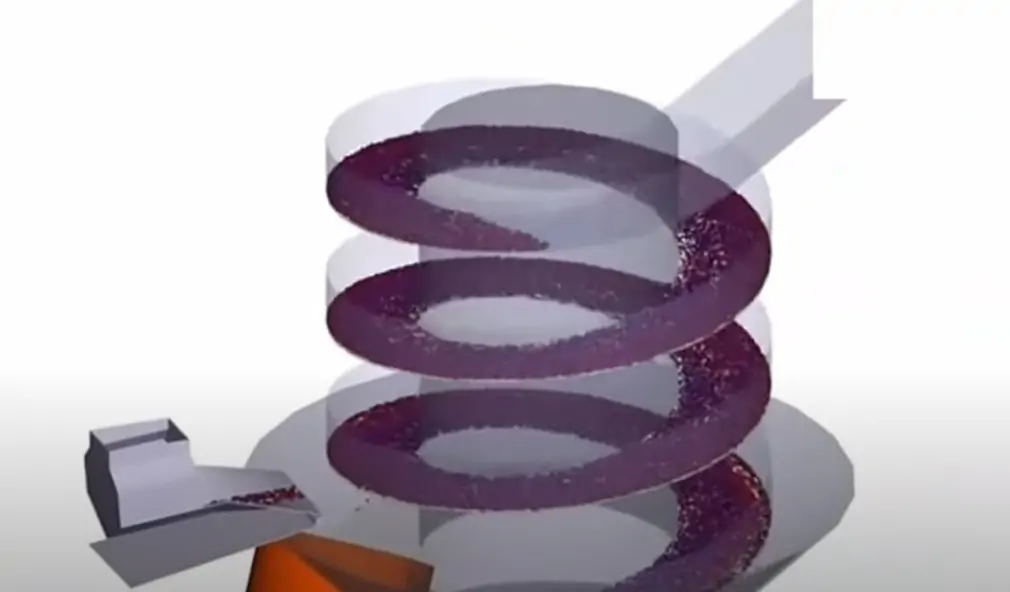

- Cooling and Conveying: The spiral lift conveyor is dedicated to cooling and conveying of high temperature casting sand. Through the cooperation of cooling devices and conveyor belts, it realizes the integration of cooling and conveying of casting sand.

Production line features

- Through the precise control of the cooling device and the sand temperature sensor, the temperature of the foundry sand during the conveying process can be ensured to be stable and moderate.

- Due to the high material temperature, the linear vibrating screen frame used for foundry sand grading adopts a hook edge design, which is resistant to high temperature and easy to replace.

- The vertical spiral lift conveyor has the ability of efficient cooling, and the material is evenly cooled during the lifting process. At the same time, it occupies a small space and has low energy consumption. It is an ideal choice for saving space and cost.

Sanyuantang is a leading manufacturer and supplier of cooling vertical elevators in China. We have rich experience in project design of cooling and lifting conveying production lines, and can provide you with customized solutions for a variety of equipment including mixing equipment, crushing equipment, conveying equipment, screening equipment, etc. Whether it is a single link or a complete production line, we can design and manufacture according to your needs. Feel free to contact us for more information!