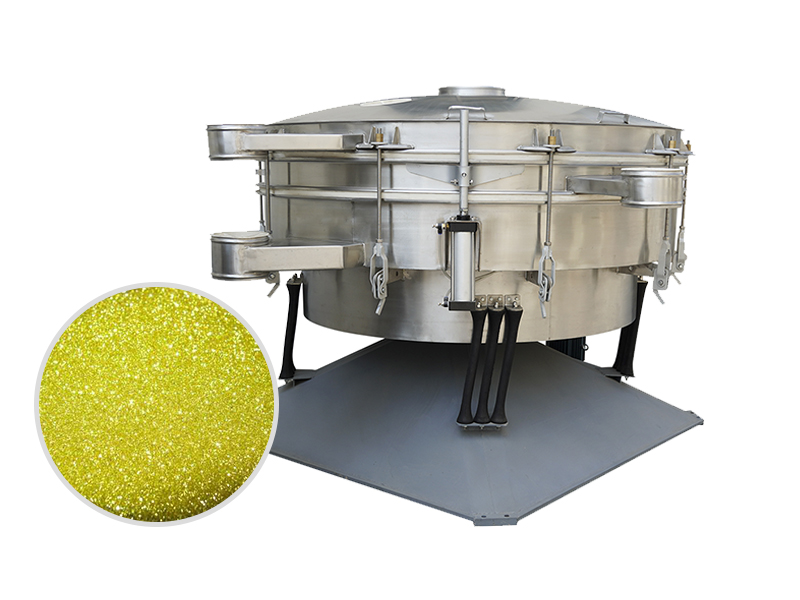

The circular vibrating screen with a round appearance is a kind of high-precision fine powder screening machinery, with low noise, high efficiency, fast mesh change that only takes 3-5 minutes, fully closed structure, and suitable for screening and filtering of granules, powder, mucus, and other materials.

The types of circular vibrating screen separators include standard circular rotary vibrating screens, swing tumbler screens, ultrasonic vibrating screens, discharge flour sifter machines, and other different models.

Types of Circular Vibrating Screen

Circular Vibrating Screen Working Principle

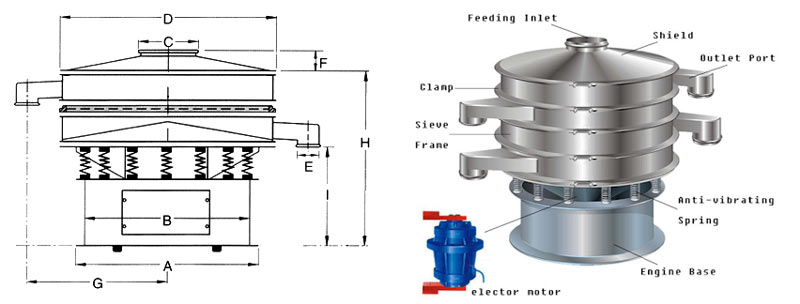

Circular vibrating screen machine is mainly composed of a vibrating motor, screen box, screen mesh and other parts. When working, the vibrating force generated by the vibrating motor is transmitted to the screen box through the spring, which makes the screen box vibrate. The material enters the screen box from the inlet, jumps and loosens on the screen mesh, the material smaller than the aperture of the screen mesh falls through the screen mesh, and the material larger than the aperture of the screen mesh continues to move forward, and is finally discharged from the discharge port. The vibration track of a round vibrating screen is round or oval, which can be adjusted according to different material properties and screening requirements.

circular vibrating screen design

The circular vibrating screen usually consists of a dust cover, a feed port, a screen, a screen, a mesh frame, and a discharge port.

Feed port: The design of the buffer plate makes the material flow into the screen surface evenly, and the material can be inspected through the observation port.

Dust cover: It limits the movement range of the material and protects the machine and the surrounding environment from dust.

Vibration motor: The vibration motor causes the vibrating screen to produce multi-plane vibration. This movement will increase the speed of materials passing through various screens.

Shock Absorbing Spring: Allows the entire upper part of the machine to vibrate freely, it helps minimize power consumption, prevents any vibration from being transmitted to the floor, and reduces noise.

Screen: maintains tension, making it easier for materials to move in the direction of vibration. This can be horizontal or vertical. One machine can separate multiple materials at the same time.

Discharge port: The size of the discharge port can be designed as needed, and the discharge speed through the valve can be adjusted as needed.

Circular Vibrating Screen Features

1. Wide screening range. The circular vibrating screen can screen various particles, fine powders, and slurries. Screen apertures range from 0.01mm to 30mm and can be assembled as required.

2. The mesh is anti-clogging. The circular motion vibrating screen function and the automatic cleaning and clogging device can knock out the materials stuck in the screen.

3. Single-layer or multi-layer sorting. The high-efficiency circular vibrating screen can be selected from one to five layers of screen mesh and can perform two to six levels of sorting or filtration at the same time.

4. High-efficiency and precise screening. Materials from the circular rotary vibrating screen are automatically discharged, and there is no material stored in the machine. Screening machines with the same screen surface have larger capacities than other types of screening machines.

5. Screen replacement is convenient. The circular vibrating screen sifter has a variety of grid structures according to different needs; one of them reduces the time of screen replacement to 3 to 5 minutes, saving 30 to 60 minutes compared with other types of screening machines. The screen lasts longer and is more efficient.

6. There is no mechanical transmission of vibration. The three-dimensional vibration generated by the new vibration source of the circular rotary vibrating screen is strong and stable. The equipment can be installed in any desired position and is easy to move.

7. Economical and environmentally friendly. The long life of the whole machine and screen, low energy consumption, low maintenance costs, high efficiency, and easy replacement make the equipment economical and affordable. Low noise, fully enclosed, and outstanding environmental performance.

Working Video

Want to see more product and factory videos? please click here.

Circular Vibrating Screen Price

The following is a price reference table for different models of circular vibrating screens, but the specific price depends on many factors, such as material, diameter, number of layers, screen, power, and other customized functions.

| Model | Screening Diameter(mm) | Power(kw) | Granularity(mm) | Voltage(V) | Price($/sets) |

|---|---|---|---|---|---|

| SYT-400 | 350 | 0.18 | <10 | 380 | 599~899$ |

| SYT-600 | 550 | 0.25 | <10 | 380 | 799~1099$ |

| SYT-800 | 750 | 0.55 | <10 | 380 | 999~1499$ |

| SYT-1000 | 920 | 0.75 | <10 | 380 | 1299~1699$ |

| SYT-1200 | 1120 | 1.1 | <10 | 380 | 1499~1899$ |

| SYT-1500 | 1420 | 1.5 | <10 | 380 | 1699~1999$ |

| SYT-1800 | 1720 | 2.2 | <10 | 380 | 1899~2099$ |

3 Aspects that Affect the Circular Vibrating Screen Price

1. Product model

Different models of circular vibrating screens have different motor powers, different equipment sizes, different numbers of layers and screen customization, etc. also determine the price of the circular vibrating screen. Therefore, users also need to choose the appropriate circular vibrating screen model based on their actual situation, site size, purpose, and function.

2. Quality and material

The material of the circular vibrating screener is divided into a carbon steel vibrating screen and a stainless steel vibrating screen. The difference in quality and material directly affects the price and service life of the circular vibrating screen.

3. Factory scale and supply capacity

The price of a circular vibrating sieve also depends on the cost invested by the manufacturer in production, as well as the management and sales costs directly caused by factors such as product research and development. Therefore, when users choose circular vibrating screens, they must choose brand products with high product quality, long service life, and reasonable prices.

Conclusion

In summary, we have provided an overview of the types, working principles, characteristics, applications, and prices of circular vibrating screens. Before purchasing a vibrating screen, tell the manufacturer your screening requirements, product application, and processing material characteristics. If you have any questions about circular vibrating screens, please contact us.