In the screening industry, the tennis ball cleaning vibrating screen has long been the preferred choice for many enterprises. It removes screen blockage through continuous collision between the vibrating screen mesh and bouncing balls. The structure is simple, maintenance is convenient, and the cost is relatively low. For many powder and granular materials, this cleaning method can achieve satisfactory results under certain conditions.

However, as the industry’s requirements for cleaning precision, cleaning uniformity, operational stability, and long-term maintenance cost increase, more and more enterprises are considering replacing the traditional ball cleaning method with an ultrasonic cleaning system. As an excellent enterprise located in the China Vibration Capital, Sanyuangtang Machinery, we have more than 30 years of experience in screening equipment manufacturing and modification. Our products are exported globally and distributed in many countries and regions around the world. Through multiple actual projects, we have accumulated relatively complete experience in replacing the ultrasonic vibrating screen. This article is mainly based on the actual replacement process and is intended for procurement personnel and engineers to reference.

Why Replace with Ultrasonic Cleaning System

Let us first look at the changes in actual operating conditions

Cleaning Effect

Ultrasonic cleaning, where the ultrasonic generator converts electrical energy into high-frequency mechanical vibrations, typically at 20kHz, 40kHz, or higher frequencies, can effectively remove deposits on the screen surface, especially for fine particles and sticky materials.

Screen Mesh

Traditional ball cleaning can cause fatigue, deformation, and wear of the screen mesh due to long-term impact. Ultrasonic cleaning mainly transmits energy, resulting in less mechanical impact.

Better Adaptation to Complex Materials

For some high-viscosity, easily blocked, and difficult-to-clean materials, ultrasonic cleaning often provides more stable cleaning performance.

However, it must be emphasized that ultrasonic cleaning is not a direct replacement. It has higher requirements for equipment structure, installation method, and matching of supporting components. From our actual projects, we have summarized the following five-step replacement process to reduce modification risks effectively.

Ultrasonic Cleaning System Replacement Process: Five Steps

Confirm the Diameter of the Vibrating Screen Size Consistency

The first step is to confirm the diameter of the existing vibrating screen, the installation aperture of the screen mesh, and the thickness of the screen mesh. The ultrasonic vibrating screen mesh must be consistent with the vibrating screen size; otherwise, it may cause installation difficulties, poor sealing, or uneven screen mesh stress.

We suggest procurement personnel prepare the following information

- Outer diameter of the vibrating screen and screen mesh aperture

- Thickness and structure of the screen mesh

- Model and manufacturer information of the vibrating screen

Purchase the Ultrasonic System and Matching Screen Mesh

The ultrasonic system usually consists of a generator, transducer, and installation structure. The screen mesh needs to match the ultrasonic system. The key points are

- Whether the power and frequency match the material and screen mesh structure

- Whether the screen mesh material is compatible with ultrasonic

- Whether the coupling method is a reliable contact method between the transducer and the screen mesh

In our practice, a mismatch between the screen mesh and the ultrasonic system is one of the main reasons for poor effect. If you want to improve screening efficiency and cleaning performance, the matching of ultrasonic mesh cleaning systems must be ensured.

Confirm the Ultrasonic Type and the Opening Position Size, Most Critical Step

The installation position of the ultrasonic transducer must be consistent with the opening of the screen machine; otherwise, effective coupling cannot be achieved. We recommend confirming with the manufacturer before modification

- Position and size of the opening

- Quantity and layout of the openings

- Connection method between the transducer and the screen machine structure

If the opening size deviates significantly, it may lead to unstable installation, energy loss, or even equipment damage.

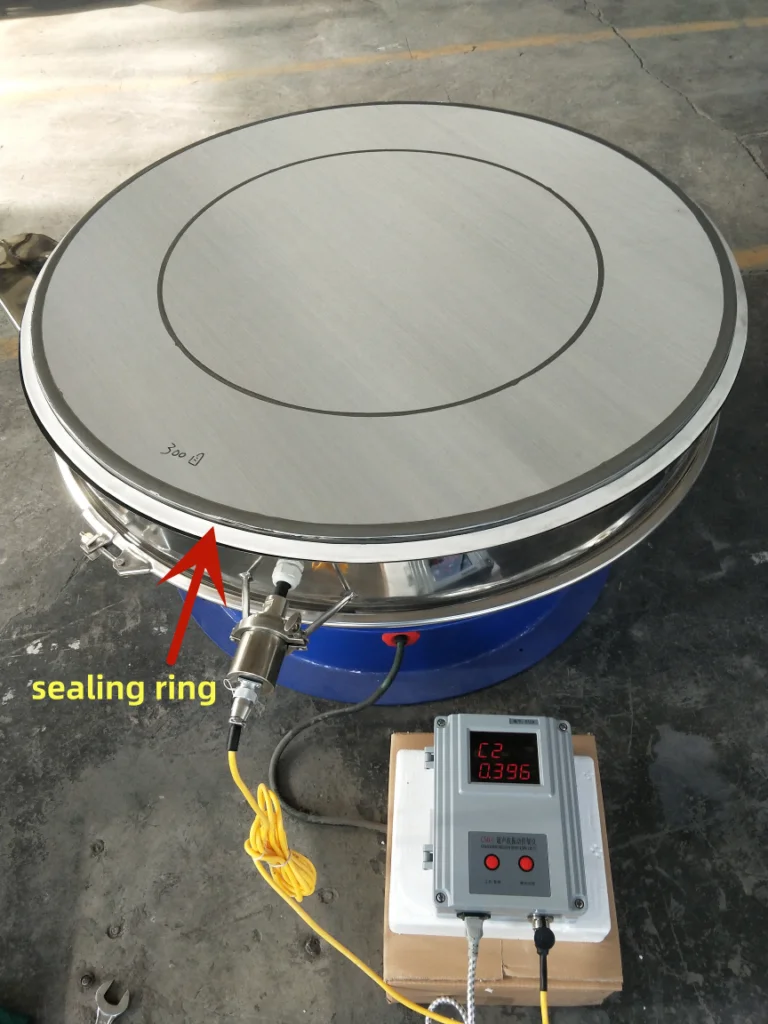

Select the Matching Seal Ring

The installation of the ultrasonic screen mesh requires a seal ring to ensure airtightness and structural stability. The selection of the seal ring should consider

- Resistance to ultrasonic vibration

- Compatibility of material with the screen mesh

- Appropriate hardness of the seal ring, too hard or too soft, affects the effect

Many modification projects ignore the matching of seal rings, resulting in material leakage, air leakage, or screen mesh loosening, which affects long term operational stability.

Replace the Screen Mesh Fixture Installation Structure

The fixture structure of the traditional ball cleaning screen mesh tends to be mechanical fixation, while the ultrasonic vibrating screen emphasizes coupling and energy transmission. Therefore, the fixture needs to be modified or replaced to ensure

- Sufficient contact area between the screen mesh and the fixture

- The fixture does not obstruct ultrasonic transmission

- The screen mesh will not loosen or shift after installation

Suggestions and Precautions After Replacement

After completing the above five steps, the cleaning method of the screen machine can be replaced from ball cleaning to ultrasonic cleaning. We recommend reserving sufficient time for installation and debugging before replacement, and confirming the power matching of the ultrasonic system in advance.

At the same time, procurement personnel should prepare a screen mesh replacement and maintenance plan, because ultrasonic screen cleaning systems have higher requirements for screen mesh, and the maintenance cycle is different from the traditional method.

Conclusion

As a manufacturing enterprise located in the China Vibration Capital, Sanyuangtang Machinery has more than 30 years of manufacturing experience, and our products are exported globally and distributed worldwide. We have completed the replacement from tennis ball cleaning vibrating screens to ultrasonic cleaning systems in multiple actual projects, and have summarized the above experience process. We hope this sharing can help procurement personnel and engineers who are considering modifications to reduce risks and improve efficiency.

If you encounter any technical issues during the modification process, please feel free to contact us. We can further confirm the matching solution based on your screen machine model, material characteristics, and operating conditions.

Email: info@sanyuantang.com

Phone: +86-18639095165