When faced with strict standards and requirements for screening drugs, the circular vibrating screen separator is essential for screening pills and powders in the pharmaceutical industry. The pharmaceutical vibratory separator provides high-efficiency and accurate screening, contributing to pharmaceutical products’ quality control and safety assurance.

The raw materials of drugs are a variety of powders, crystals, extracts, etc. prepared by chemical synthesis, plant extraction, or biotechnology for medicinal purposes, but patients cannot directly take them, and require further processing. Among the raw materials, organic synthetic drugs’ variety, output, and output value account for a large proportion, which is the main pillar of the chemical pharmaceutical industry.

The quality of the API determines the quality of the preparation, so its quality standards are very strict, and countries around the world have formulated strict national pharmacopeia standards and quality control methods for its widely used APIs. Usually, the screening mesh size is about 24-100 mesh, with adhesion, adsorption, and easy to block the characteristics of the net.

In the face of such strict standards, We have two pharmaceutical vibratory screener solutions: rotary vibrating screen separator and ultrasonic vibrating screen separator. They have different features, but how to choose the right vibratory separator machine for screening the drugs?

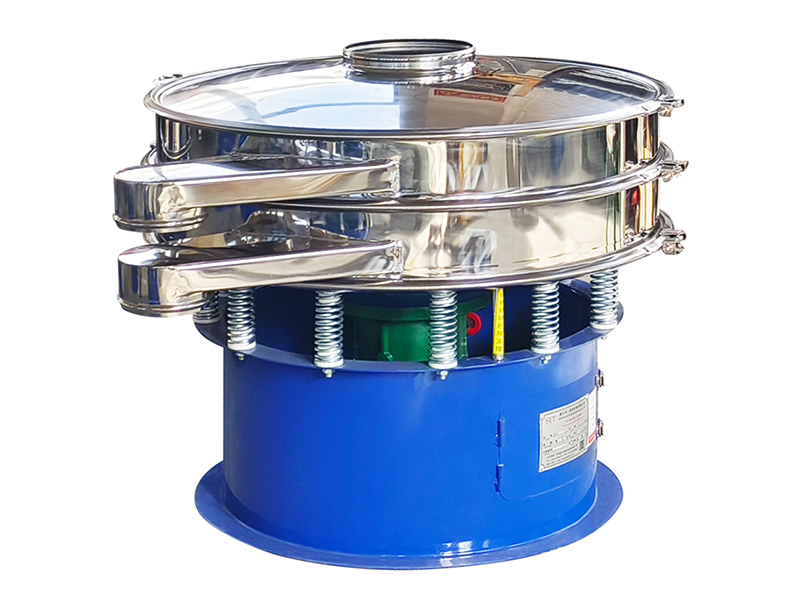

Rotary Vibrating Screen Separator

The round vibrating screen separator profile mesh frame is strictly by the ISO9001 quality management system to produce, screening efficiency is high, screen welding is smooth, uniform mesh layout, for the drug pill particle size, adhesion, API specifications are different, can effectively screen, high material pass rate. The use of stainless steel material, clean and easy to clean, can meet the production standards of the pharmaceutical industry.

Features

- High screening efficiency, compact and durable design, any powder, or mucus can be screened.

- Easy to change the net, simple operation, easy to clean.

- The stainless steel rotary vibrating screen separator fully closed structure and the powder does not fly, but also prevents the entry of pollutants.

- Can be sieved up to 500 mesh or 0.028mm. Very suitable for the screening of drugs.

Ultrasonic Vibrating Screen

The ultrasonic vibrating screen is based on the traditional vibrating screen and then introduces a low amplitude, high-frequency ultrasonic vibration sieve (mechanical wave) on the screen superimposed on the screen a high frequency and low amplitude ultrasonic vibration meter, ultrafine powder to accept huge ultrasonic acceleration, so that the material on the screen surface always maintain a suspended state, thereby inhibiting adhesion, friction, flat fall, and other factors.

Very effectively solves strong adsorption, easy agglomeration, high static electricity, high fine, high density, light gravity, and other screening problems, so that ultrafine powder screening is no longer difficult, especially suitable for high-quality, fine powder users. It can be easily solved for the problems of easy paste, adsorption, screen blocking, and so on, and is very suitable for the screening of raw materials. It can increase the passing rate of the screen by 50%-400%.

Conclusion

Both vibrating screens offer advantages in different situations, and the choice between them will depend on the specific characteristics of the APIs being screened and the requirements of the pharmaceutical process. We should carefully evaluate the specific needs of our customers to determine the most suitable screening scheme for them, to recommend the most suitable model of machine.

More Products

Related Articles

- The Role Of Sieving Machine In Pharmaceuticals

- Pharmaceutical Screening Equipment: Efficient Particle Separation for the Pharmaceutical Industry

- The Comprehensive Guide To Pharmaceutical Vibro Sifter: Working Principles, Uses, And Types

- Circular Vibrating Screen Separator In Pharmaceutical

- Different Types Of Vibrating Screens And Price