We provide this FAQ for Ultrasonic Sieve Shakers to help you achieve optimal performance during operation.

First, let’s clarify a few concepts:

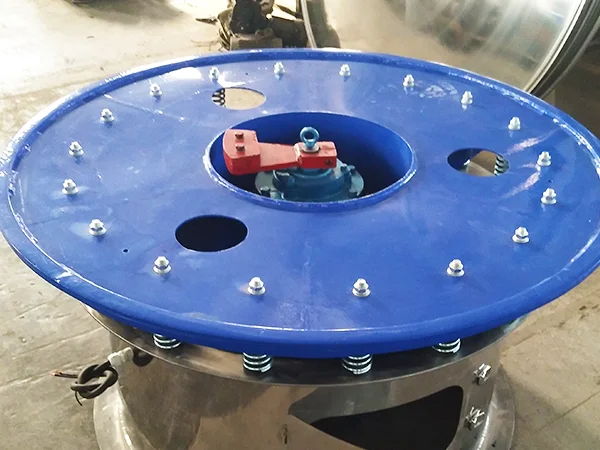

- A sieve shaker is a device that uses physical vibration to drive a sieve mesh, achieving material classification and impurity removal.

- Ultrasonic sieve shakers incorporate an ultrasonic system into traditional sieve shakers, adding three-dimensional motion to enhance precise screening of fine powders and sticky materials while reducing the likelihood of screen clogging.

- Ultrasonic lab sieve shakers leverage high-frequency ultrasonic technology for precise screening of fine powders and sticky materials, primarily used for testing and inspection across industries. Applications include laboratory particle size analysis, pharmaceutical fine powder screening, food ingredient impurity removal, and micro-grading of new materials.

Common Issues and Solutions for Ultrasonic Sieves

Low Screening Efficiency

Causes:

- Insufficient ultrasonic system power fails to break material agglomerates, particularly affecting fine powder screening in ultrasonic lab sieve shakers;

- Inappropriate mesh size, clogged or damaged screens fail to meet the separation function defined for sieve shakers.

- Excessive feed volume exceeds the equipment’s processing capacity.

- High material moisture causing adhesion to the screen.

Solutions:

- Increase the ultrasonic generator power.

- Replace with a suitable screen, ensuring flat installation and proper sealing.

- Control feed rate.

- Dry high-moisture materials or apply anti-adhesive agents.

Generator fails to start

Causes:

- Poor power connection or voltage mismatch, failing to meet the power requirements defined for sieve shakers.

- Generator fuse blown.

- Damaged generator mainboard or components.

Solutions:

- Inspect power circuit to ensure voltage meets ultrasonic sieve specifications.

- Replace fuse with identical rating (perform after power disconnection).

- Contact manufacturer for repair; do not disassemble.

Reduced vibration/amplitude

Causes:

- Loose transducer-to-screen connection or contaminants.

- Transducer aging, affecting the precision application of the ultrasonic lab sieve shaker.

- Generator power knob malfunction or incorrect parameter settings.

Solutions:

- Power off, tighten connection bolts, and clean contact surfaces.

- Replace with a compatible spare transducer.

- Inspect the knob, re-calibrate parameters, or restore factory settings.

Frequent Screen Clogging

Causes:

- High material viscosity, presence of fine powder/fibers, affecting the screening function of the ultrasonic lab sieve shaker.

- Ultrasonic system not operational, causing the ultrasonic sieve to lose its anti-clogging advantage.

- Insufficient screen tension, violating the vibration principle defined for sieve shakers.

Solutions:

- Add inert powder, use hot air for assisted screening, or pre-treat to remove fibers.

- Repair ultrasonic system to ensure high-frequency vibration transmission.

- Adjust screen tensioning device to maintain flatness.

Short Screen Life/Prone to Damage

Causes:

- Hard impurities in material cause impact wear on screen.

- Screen material mismatched with material properties.

- Improper screen installation causing friction/collision with components.

Solutions:

- Install impurity removal device at feed inlet to protect screen.

- Select screen material based on material hardness/corrosiveness (e.g., stainless steel, PTFE).

- Properly install screen to prevent misalignment and collisions.

Excessive operational noise

Causes:

- Unstable equipment placement or loose anchor bolts.

- Wear on screen frame/body components or loose connections.

- Loose transducers generating high-frequency noise.

Solutions:

- Level the anchor bolts and add vibration-damping pads.

- Tighten component bolts, replace worn parts, and apply lubricant.

- Secure the transducer; replace if faulty.

Abnormal Vibration (Violent Shaking)

Causes:

- Uneven feeding causing eccentric material accumulation.

- Screen clogging leading to imbalanced material distribution.

- Damaged vibration motor or bearings.

Solutions:

- Adjust feeding device to ensure uniform material distribution.

- Clear screen blockages and optimize screening process.

- Check motor speed and bearing condition; repair or replace components.

Daily Maintenance and Care

1. Key Daily Maintenance Points

Before startup: Inspect power supply, screen condition, and transducer connections.

During operation: Monitor vibration noise, track generator parameters, and maintain uniform feeding.

After shutdown: Clear residual material, wipe down equipment, and record operational status.

2. Long-Term Storage of Ultrasonic System

- Clean the generator and transducer, ensuring they are dry and free of contaminants.

- Store the generator in a dry, well-ventilated environment.

- Coat the transducer with rust-preventive oil and seal it, or securely attach it to the screen mesh.

- Every 3 months, power on the generator for 10 to 15 minutes and inspect the transducer’s appearance.

Conclusion

The above covers common issues and solutions for ultrasonic sieve shakers, along with cleaning and storage methods. If you have further questions, feel free to contact us anytime. Our team is available 24/7 to assist you.