In modern industrial production, Vibro Sifter, as an important screening equipment, is often used in pharmaceutical, chemical, food, metallurgy and other industries. However, with the progress of science and technology and industrial upgrading, the traditional ordinary Vibro Sifter has been unable to meet the demand for high-precision and high-efficiency screening, so the Ultrasonic Sieving Machine began to be widely used. This article will comprehensively analyze the main differences between ordinary Vibro Sifter and Ultrasonic Sieving Machine, and provide you with equipment selection suggestions, please continue reading this article.

What is ordinary Vibro Sifter and Ultrasonic Sieving Machine, and what is the difference between their working principles?

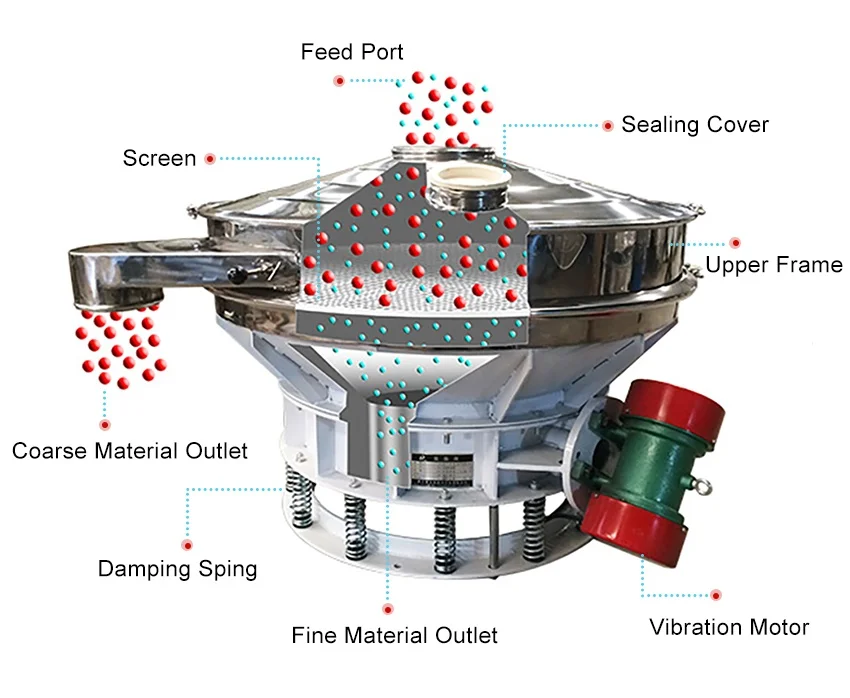

Vibro Sifter is mainly used for material classification, screening and filtration. The working principle of ordinary Vibro Sifter (i.e. rotary Vibro Sifter) is to produce three-dimensional vibration through the motor-driven exciter, so that the materials do throwing movement on the screen mesh to realize the separation of different particle sizes. Although this mechanical vibration method is simple in structure and low in cost, there are obvious limitations in dealing with ultra-fine powder and high viscous materials, such as the existence of screen mesh easy to be clogged, lack of precision and other problems.

The ultrasonic screening machine innovatively incorporates an ultrasonic screening system on top of the traditional vibrating screen. The system converts 220V, 50Hz (or 110V, 60Hz) electrical energy into 18-38KHz high-frequency mechanical vibration wave, which is transmitted to the screen surface through the transducer, so that the screen is superimposed with high-frequency low-amplitude ultrasonic vibration on the basis of the original mechanical vibration. This high-frequency vibration completely changed the limitations of a single mechanical vibration, so that the ultra-fine powder to obtain a huge acceleration, effectively overcoming the adhesion between the material, electrostatic force and other factors that hinder screening. Especially suitable for fine powder screening.

From the technical principle, the fundamental difference between the two kinds of Vibro Sifter lies in the energy transfer mode and vibration frequency. Ordinary Vibro Sifter relies on mechanical vibration, the frequency is usually in 1460 times / sec (about 24.3Hz) or so; and Ultrasonic Sieving Machine ultrasonic frequency as high as 36000 times / sec (36KHz), is nearly 25 times the former. However, Ultrasonic Sieving Machine is not simply adding ultrasonic device on the ordinary screen machine, but through the precise coordination of vibration parameters and ultrasonic frequency, to realize the two vibration modes.

Comparative analysis of ordinary Vibro Sifter and Ultrasonic Sieving Machine

Ordinary Vibro Sifter and Ultrasonic Sieving Machine in the core technology level there are obvious differences, these differences also determine the scope of its application. Understanding the difference between these technologies helps enterprises to make the choice of equipment models according to their own production needs.

Vibration principle and frequency

Ordinary Vibro Sifter relies on the mechanical vibration generated by the rotation of the eccentric block for screening, and its vibration frequency is relatively low, usually 1460-2800 times per minute (about 24.3-46.7Hz). Although this vibration method can effectively deal with general granular materials, but not for ultra-fine powder or special properties of the material screening. In contrast, the Ultrasonic Sieving Machine retains the mechanical vibration at the same time, through the ultrasonic transducer will be converted into high-frequency mechanical wave, superimposed on the screen mesh ultrasonic vibration frequency as high as 18-38KHz (i.e., 18,000-38,000 times / sec), is hundreds of times that of the ordinary Vibro Sifter. This high-frequency, low-amplitude ultrasonic vibration makes the material get huge acceleration and reduces the clogging of the screen.

Screening precision

The screening precision of ordinary Vibro Sifter is generally about 60%-70%, which is difficult to meet the demand for high-precision screening. The Ultrasonic Sieving Machine can make the material suspended in the screen surface by virtue of the “micro vibration” effect of ultrasonic wave, which significantly improves the screening rate, and the screening precision can reach more than 95%.

Mesh cleaning method

Ordinary Vibro Sifter usually adopts bouncing ball mesh clearing device, which prevents the mesh from being clogged through the impact of bouncing ball, and is suitable for screening granular materials, not suitable for screening fine powder. The Ultrasonic Sieving Machine has self-cleaning function – the ultrasonic vibration wave generated by it can continuously keep the mesh open, and it can prevent blockage without additional mesh clearing device, which is especially suitable for ultra-fine screening operation above 500 mesh. Moreover, in practical application, ordinary Vibro Sifter often has to stop frequently to clean up due to the problem of clogging mesh, while Ultrasonic Sieving Machine can realize continuous 24-hour operation, which greatly improves the production efficiency.

Characteristics of processing materials

Ordinary Vibro Sifter is suitable for most of the conventional granular materials, but it is less effective in dealing with special materials with strong adsorption, easy agglomeration, high static electricity, high fineness, high density or light specific gravity. Ultrasonic Sieving Machine is specially designed to solve these difficult to screen materials, such as nanomaterials, pharmaceutical powder, metal micropowder and other high value-added fine powders. Ultrasonic acceleration can effectively break the intermolecular force between the materials to solve the problem of agglomeration; high-frequency vibration can eliminate the effect of static electricity to prevent the powder from sticking to the screen.

Table: comparison of core technical parameters between ordinary vibrating screen and ultrasonic vibrating screen

| Technical Parameters | Ordinary Vibro Sifter | Ultrasonic Sieving Machine | Advantage Comparison |

| Vibration Frequency | 24.3–46.7 Hz | 18–38 kHz | Ultrasonic frequency is 600–1500× higher |

| Screening Accuracy | 60%–70% | >95% | Accuracy improved by 25%–35% |

| Cleaning Method | Mechanical (bouncing balls) | Ultrasonic self-cleaning | Eliminates clogging in ultrafine powders |

| Applicable Particle Size | 20–400 mesh | 10–635 mesh | Extends range to finer particles |

| Material Adaptability | Standard granular materials | Challenging-to-screen materials | Solves 7 major screening difficulties |

As a result, it has become increasingly difficult for conventional Vibro Sifters to meet the requirements of the fine screening industry, while ultrasonic systems offer a reliable solution for fine screening. However, Ultrasonic Sieving Machines also have a disadvantage, it is not suitable for large particles of material (usually more than 2mm) screening.

Material adaptability

Ultrasonic Sieving Machine has unprecedented material adaptability, can easily deal with a variety of difficult to screen materials. Specifically in the following aspects: for light specific gravity materials (such as graphene, aerogel, etc.), ultrasonic vibration to offset the problem of insufficient gravity settlement; for high-density metal powder (such as tungsten powder, cobalt powder), ultrasonic vibration prevents the particles from wedging into the mesh; for easy to agglomerate materials (such as nano-materials, pharmaceutical powders), high-frequency vibration breaks the agglomerative force between the particles; for highly electrostatic materials (such as plastic micropowder, pharmaceutical powders), ultrasonic neutralization of surface charge. ), ultrasonic waves neutralize the surface charge.

In addition, Ultrasonic Sieving Machine can better maintain material properties. Whereas the mechanical impact of ordinary Vibro Sifters may cause brittle particles to break or crystal structure to change, the gentle vibration mode of Ultrasonic Sieving Machines avoids these problems. In the pharmaceutical and food industries, where the integrity of the active ingredient has a direct impact on product efficacy, Ultrasonic Sieving Machines are an ideal solution for the pharmaceutical industry.

Table: The advantages of Ultrasonic Sieving Machines in various industries

| Industry | Typical Materials | Screening Challenges | Ultrasonic Solution | Performance Improvement |

| Pharmaceutical | Medicine powder, Vitamins | Strong adhesion, easy agglomeration | Breaks intermolecular forces, prevents clumping | Accuracy ↑30%, Cross-contamination ↓90% |

| Chemical | Titanium dioxide, Cobalt powder | High static, easy clogging | Neutralizes static, self-cleaning mesh | Output ↑3×, Energy consumption ↓15% |

| Food | Flour, Seasonings | Low density, poor flowability | Suspends particles, improves flow | Efficiency ↑200%, Hygiene compliance |

| Metallurgy | Tungsten powder, Molybdenum powder | High density, easy wedging | High-frequency vibration releases particles | Screen life ↑5×, Purity ↑25% |

| Electronics | Silicon micro powder, Solder powder | Strict particle size requirements | Precise separation of similar sizes | Yield ↑40%, Waste ↓60% |

Easy operation and maintenance cost advantage

From the perspective of long-term use, Ultrasonic Sieving Machine also has the advantages of easy operation and low maintenance cost. The equipment adopts modularized design, and it takes only 3-5 minutes to change the screen, which saves a lot of time compared with ordinary Vibro Sifter. Intelligent ultrasonic generator can automatically adjust the parameters to adapt to different material characteristics, without the need for frequent adjustment by professionals.

In contrast, the screen mesh of Ultrasonic Sieving Machine has a longer service life. The screen mesh of ordinary Vibro Sifter is often damaged due to forced cleaning after blocking the mesh, and it is frequently replaced; while the screen mesh of Ultrasonic Sieving Machine works under mild high-frequency vibration, without mechanical impact, and its service life can be extended by 3-5 times. Long-term statistics show that although the initial investment in Ultrasonic Sieving Machine is higher, the comprehensive cost of use within 3 years is lower than that of ordinary Vibro Sifter.

Typical application case analysis

The successful application of Ultrasonic Sieving Machine in various industries has fully proved its technical advantages and value. Through specific case studies, we can more intuitively understand how Ultrasonic Sieving Machine can solve practical production problems, and provide valuable reference for users in related industries.

Pharmaceutical industry: high value-added drug powder precision screening

In the pharmaceutical field, the screening of active pharmaceutical ingredients (API) has been facing serious challenges. A well-known pharmaceutical company in the production of an anti-tumor drug, the use of ordinary Vibro Sifter screening 200 powder, screening efficiency of less than 50%, and due to electrostatic adsorption leading to a large number of loss of active ingredients, the more serious is the frequent blocking of the network leading to every 30 minutes of work must be stopped to clean up. After the introduction of Ultrasonic Sieving Machine, the situation has been fundamentally improved: screening efficiency increased to 97%, the recovery rate of active ingredients increased by 35%, and the continuous working time was extended to more than 8 hours. What’s more, the consistency of the product batch was significantly improved, and the difference in content uniformity was reduced from the original 15% to less than 5%, which is in full compliance with the strict requirements of GMP.

New chemical materials: precise grading of nanoscale materials

The screening of nanomaterials in the chemical industry places extremely high demands on equipment. A carbon nanotube manufacturer needs to classify products with different diameters, and initially the use of ordinary Vibro Sifter could not complete the fine screening of 500 mesh, and had to use the costly airflow classification process. Configuration of Ultrasonic Sieving Machine, not only to achieve a 635 mesh (about 20 microns) of accurate classification, the output also reached the original airflow classification of three times, while energy consumption is only 1/5 of the latter. especially worth mentioning, the Ultrasonic Sieving Machine closed design to avoid the escape of nanometer dust, to solve the environmental pollution problems that have long plagued the workshop.

Food industry: screening solutions for high hygiene requirements

The food industry has special health and safety requirements for sieving equipment. An international food company’s flour sieving process has long faced two major problems: first, the poor fluidity of flour leads to low sieving efficiency; second, the ordinary Vibro Sifter is difficult to thoroughly clean, there is a risk of microbial contamination. The Ultrasonic Sieving Machine’s all stainless steel structure and dead-angle-free design perfectly solved these problems: the material flow under the action of ultrasound improved dramatically, and the output increased by 2.5 times; the equipment can be completely disassembled and cleaned with the CIP system, and the hygiene index compliance rate increased from 85% to 100%.

Seasoning screening is another success story. A seasoning enterprise produces a kind of compound seasoning powder containing oil and grease components, it is very easy to adhere to the screen, the ordinary Vibro Sifter work 10 minutes after the efficiency will drop more than 50%.1 After installing the Ultrasonic Sieving Machine, the problem of adhesion is basically eliminated, and the screening efficiency is still maintained at more than 95% after 8 hours of continuous work. At the same time, the gentle treatment of Ultrasonic Sieving Machine avoids the loss of heat-sensitive aroma in the seasoning, and the sensory quality of the product is significantly improved.

Electronic materials: stringent particle size requirements

The electronics industry has nearly harsh requirements on the particle size distribution of materials. The alumina powder of an electronic ceramics enterprise needs to strictly control the content of +325 mesh and -500 mesh, and the ordinary Vibro Sifter simply cannot meet this requirement. After the introduction of Ultrasonic Sieving Machine, it not only realizes the precise classification of 635 mesh, but also separates multiple particle size segments at one time through multi-layer design, simplifying the process. The product particle size compliance rate increased from the original 70% to 99%, and the customer complaint rate dropped to zero.

When to choose to choose ultrasonic vibrating screen?

Through the above content, we have understood the difference and advantages between ultrasonic vibrating screen and ordinary vibrating screen, and come up with the following scenes suitable for choosing ultrasonic vibrating screen:

- Special material characteristics: choose ultrasonic vibrating screen according to the characteristics of the material, such as strong adsorption (such as pharmaceutical powder), easy to agglomerate (such as nano-materials), high electrostatic (such as plastic micropowder), high fine (more than 500 mesh), high-density (such as metal powders) or light specific gravity (such as graphene) and other difficult to sieve materials.

- High precision requirements: when the product particle size distribution requirements are strict, ordinary vibrating screen is difficult to meet the standard, you can choose ultrasonic vibrating screen. Such as medicine, electronics, high-end chemical industry and other fields.

- Large capacity demand: in the high-precision and mass production scenarios, ultrasonic vibrating screen can be selected, and the high throughput rate of its screen can reduce the number of equipment and save space and labor costs.

- High hygiene standards: food, pharmaceutical and other industries need fully enclosed, easy-to-clean design to avoid cross-contamination.

- Automation needs: ultrasonic vibrating screen is easier to integrate with automatic feeding and receiving system to realize 24-hour continuous production.

In summary, for the screening of ordinary granular materials (20-200 mesh), and when the capacity and precision requirements are not high, ordinary vibrating screen is still an economical choice. In addition, small and medium-sized enterprises with limited budgets can also consider investing in phases and then upgrading the ultrasonic system for key processes.