What is an Inline Sifter?

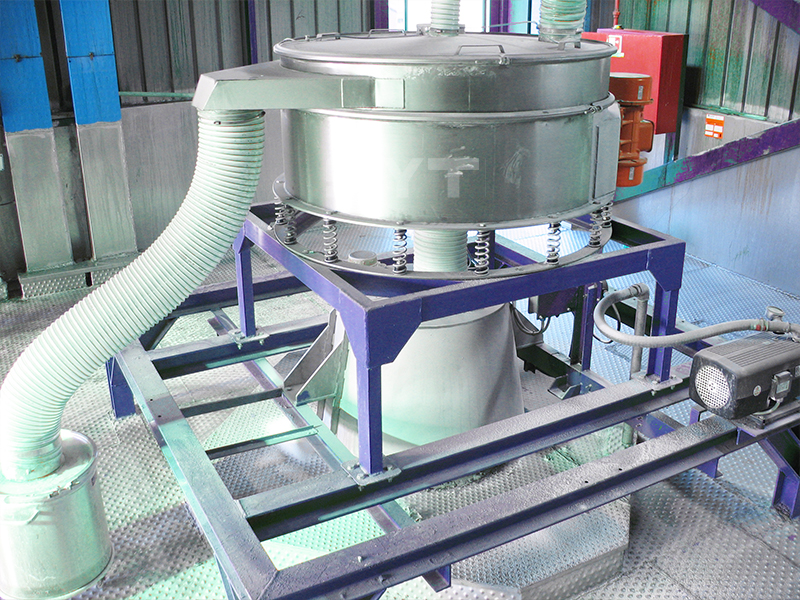

Inline Sifter is a kind of screening equipment commonly used for screening in food, chemical, pharmaceutical, plastic and other industries. It is a high-efficiency screening equipment that utilizes one or two vibration motors to generate the excitation force.

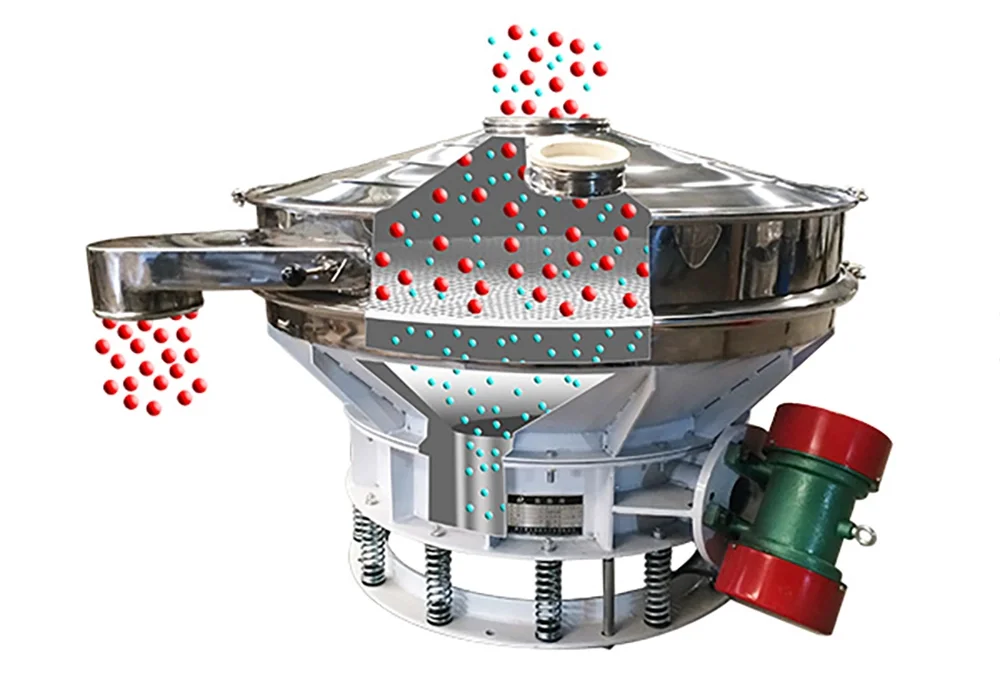

Under the three-dimensional movement of the screen mesh, fine material passes through quickly, while coarse material is discharged from the side discharge port. Especially in dealing with plastic particles, grain, sugar, salt, fertilizer, mineral particles and other materials in the removal of impurities, grading more common, and in line with the food, medicine and other industries on the health requirements.

Here we come together to understand the common problems encountered in the food industry and the advantages of inline sifter in the food industry.

Problems with sieving in the food industry

In the production process of the food industry, sieving is the key to guaranteeing the quality of raw materials and production efficiency. However, many food companies face the following challenges in actual screening operations:

- High screen clogging: Conventional screening equipment is prone to screen clogging, leading to interruptions in the production process.

- Dust contamination: Open screening operations readily cause dust dispersion, allowing contaminants to infiltrate raw materials and making it difficult to meet the stringent hygiene and cleanliness standards required in food processing plants.

- Efficiency bottleneck is obvious: manual loading easily lead to uneven distribution of materials, screening speed is limited, difficult to support large-scale, continuous production needs.

In response to the food industry’s dual demand for screening accuracy and hygiene standards, the Sanyuantang inline sifter was born to help food companies effectively solve the above problems.

Wheat Flour

Wheat Flour Cereal Grains

Cereal Grains Spices

Spices Oreo powder

Oreo powder Stevioside Powder

Stevioside Powder Medicine Powder

Medicine Powder Lees

Lees Medicine

Medicine Plastic Additives

Plastic Additives Plastic Particles

Plastic Particles

Inline Sifter solutions in the food industry

In response to the needs of thousands of enterprises, the technical team of Sanyuantang has given a combination of “customized hopper + inline sifter”:

| Problems with sieving in the food industry | Inline Sifter solutions in the food industry |

| High screen clogging | Uniform feeding prevents clogging and blockages |

| Dust contamination | Enclosed design with food-grade materials |

| Efficiency bottleneck is obvious | Automatic feeding and discharge |

- Uniformly less material, anti-clogging: The large-capacity hopper is installed on the top, and the material flows into the sifter automatically, avoiding the clogging problem caused by uneven manual loading.

- Fully enclosed design, zero dust: screen box sealing structure + negative pressure dust removal interface (optional), the workshop air cleanliness up to standard.

- Intelligent discharge, save labor: multi-layer screen classification design, finished products, impurities automatically diverted to different outlets, without the need for secondary sorting.

Additionally, the Inline Sifter features a high-quality stainless steel construction compliant with GMP standards, offering exceptional hygienic performance and durability. Its linear vibration design enhances material distribution uniformity, thereby improving screen utilization. Furthermore, it supports integration with automated conveying and packaging systems to meet continuous production requirements.

Main advantages of Inline Sifter

When selecting screening equipment for food production, efficiency, hygiene, and stability are the most critical considerations. The Inline Sifter combines high-efficiency vibration technology, stringent hygiene protection, and compatibility with automated production lines, making it the ideal choice for continuous, high-precision food screening.

- Large processing capacity: direct and smooth material flow path, short residence time on the screen surface, especially suitable for large processing capacity requirements.

- High screening efficiency: strong three-dimensional vibration effectively prevents clogging of the screen holes (especially for granular materials with a certain degree of mobility) and improves the screening throughput rate.

- Can be installed on the production line: The inline sifter machine can be directly installed on the production line, with material processing rates matching production speeds. It also features a sealed feed inlet to minimize foreign object ingress.

- Relatively simple structure: Inline Sifters typically feature only one or two layers of screen mesh, boasting a compact design that occupies relatively little floor space.

- Easy to clean and maintain: the screen frame structure is usually designed as a quick-open type, it is convenient to replace the screen mesh and clean the interior, in line with the requirements of food, medicine and other industries on the hygiene.

- Good material adaptability: Especially suitable for dealing with granular, good fluidity, moisture content is not high, not easy to caking materials in the removal of impurities, classification.

Common Functions of the Inline Sifter

Removal of Impurities/Foreign Objects: During food processing, clumping or impurities often occur due to viscosity, moisture, or incomplete raw material cleaning. The Inline Sifter removes clumps, large particles, or foreign objects from the material.

Classification: Products are typically graded based on quality and purity to determine acceptance or classification. The Inline Sifter can separate material into two categories (single-screen) or three categories (dual-screen).

Standardizing Output: The screen mesh aperture is fixed, ensuring the particle size of screened material falls within a narrow tolerance range. This guarantees consistent quality for products processed through the Inline Sifter.

Suitable Materials: Plastic pellets, sugar, salt, flour additives, monosodium glutamate (MSG), fertilizers, feedstuffs, quartz sand, metal powders, pills/tablets, seeds, etc.

FAQs Regarding the Use of Inline Sifters in the Food Industry

Q1: Can an inline sifter process all materials with a single screen?

A1: No. Vibrating screens require different mesh sizes and materials based on the material’s particle size, viscosity, and other properties.

Q2: Is the Inline Sifter expensive to maintain? Is maintenance complicated?

A2: No. The equipment features a simple structure and stable operation. Primary daily maintenance involves periodic screen cleaning and vibration motor inspection. Utilizing high-strength stainless steel and anti-clogging design ensures a long service life and low overall maintenance costs.

Q3: What distinguishes the Inline Sifter from the Rotary Vibrating Screen?

A3: The inline sifter machine integrates directly into production lines, connecting with other manufacturing processes to enhance automation. Compared to the Rotary Vibrating Screen, it features a more compact structure, superior sealing, and enhanced hygiene—making it ideal for food production lines demanding strict cleanliness and continuous operation.

For a detailed comparison of both equipment types, please refer to the following article: Rotary Vibrating Screen VS Inline Vibratory Screen

Q4: Does the equipment meet food industry hygiene standards?

A4: Absolutely. The inline sifter machine is constructed from food-grade stainless steel, features a sealed screen housing, and is equipped with a negative pressure dust collection system, fully compliant with GMP standards.

Conclusion:

With the above solutions and understanding of inline sifter, we believe you can work faster and more efficiently with inline sifter in the food industry. If you still have more questions and concerns, you can contact us now, for we have a professional team to provide you with a more customized type of solution.e contact us immediately. Our professional team is always ready to provide technical support and services.