In the modern food processing industry, flour quality is a critical step in ensuring product texture and food safety. The Commercial Flour Sifter plays a vital role in the processing and filtering stages. Today, let’s explore its functions, working principles, and the various types available.

Functions of the Commercial Flour Sifter

Its primary functions in the food processing industry include removing impurities, enhancing purity and precision, and improving production efficiency.

Removing impurities: In raw grain, many impurities such as stones, metal shavings, and insect eggs are often mixed in. The presence of these impurities not only affects the purity, precision, and food safety of the flour but also impacts the safety of subsequent production equipment, production efficiency, and the final product’s texture and safety. The Commercial Flour Sifter can efficiently remove these impurities, ensuring food safety.

Improving Purity and Precision: In flour production, purity and precision are major issues for enterprises. Different purity levels and particle sizes result in significant differences in the texture of the final product. The Commercial Flour Sifter uses multi-layer, multi-category screens for filtration and sorting, ensuring that flour at every level is consistent in size and purity.

Enhancing Production Efficiency: During flour screening, screen blockages and leaks are common issues, requiring frequent shutdowns for cleaning and inspections, which severely impact work efficiency. The Commercial Flour Sifter is equipped with an intelligent screen cleaning system, cleaning balls, or an ultrasonic system to perfectly resolve screen blockage-related shutdowns and inspections, significantly improving work efficiency.

A high-quality best commercial flour sifter device, through precise vibration frequency control, reasonable screen structure, and efficient cleaning devices, can thoroughly remove impurities, ensure uniform flour fineness, and achieve continuous and stable production, making it the best assistant for commercial flour production.

Working Principle of the Commercial Flour Sifter:

We have understood its role in commercial flour production. Let us now explore its working principle and advantages:

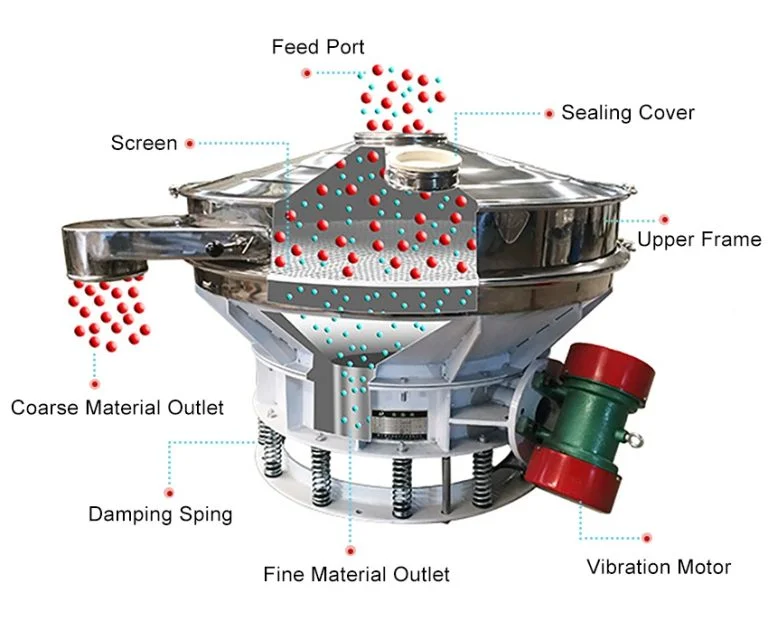

First, its vibration source:Our equipment typically uses high-efficiency vertical vibration motors as the vibration source, capable of operating either as a single unit or in a dual-machine configuration. This provides stable vibration force, enabling the material to move in a circular, vertical, three-dimensional motion.

Secondly: Depending on flour production requirements, the machine can be configured with 1-3 layers of screens with different mesh sizes (common mesh sizes: 40 mesh, 60 mesh, 80 mesh), achieving both “impurity removal + grading” in one step. When paired with ultrasonic screen cleaning or ball cleaning equipment, residual flour in the screen pores can be automatically cleaned without stopping the machine.

Working principle:

The vibrating motor generates vibrating force to make the screen frame vibrate. After the raw material is evenly distributed within the screen frame, it is subjected to the vibrating force. Larger particles move to the front under the vibrating force and are gradually discharged through the equipment’s discharge port, while smaller particles pass through the screen mesh and are discharged from the bottom. The material is discharged through the discharge port, thereby achieving the separation of materials of different particle sizes.

Advantages:

- Stainless steel construction: Not only is it wear-resistant and corrosion-resistant, preventing flour contamination caused by equipment rust, but it also easily meets daily cleaning and disinfection requirements, complying with national food safety production standards (GB 4806 series);

- Sealing device: High-quality silicone seals and dust-proof covers prevent dust leakage during screening;

- Multi-stage design: Multi-stage impurity removal and grading in one machine.

- Custom production: All accessories and machine models can be customized according to production requirements.

What types of Commercial Flour Sifters are available?

The common types of Commercial Flour Sifter equipment include the following:

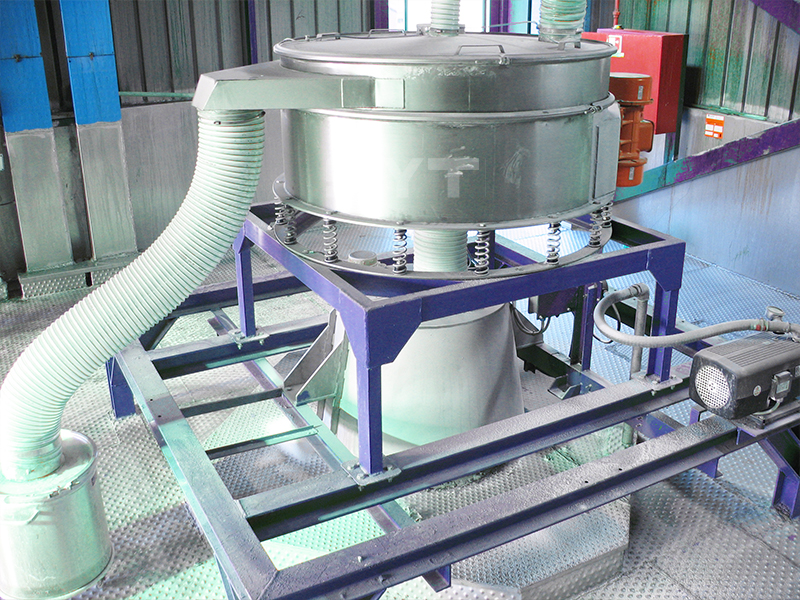

Rotary Vibrating Screen

Features: Compact size, high efficiency, and easy operation

Suitable for small and medium-sized food factories, pastry workshops, etc.

Capable of multi-layer screening with high precision

Inline Sifter Machine

Features: Strong preliminary screening capability; suitable for the food industry, especially for flour production lines; can effectively remove impurities in batches to ensure the purity of flour.

Advantages: Fine sifting, dust-free operation

Linear Screening Machine

Features: High output, high throughput

Suitable for flour mills, central kitchens, and the front end of food production lines

Can operate continuously, with simple maintenance

Conclusion:

An efficient Commercial Flour Sifter is not only a guarantee for improving product quality but also a crucial component of automated and standardized production for businesses. As a professional vibrating screen manufacturer, we are committed to providing customers with stable, durable screening equipment that meets food safety standards. If you are looking for a flour sifter suitable for commercial use, please contact us for free technical consultation and quotation proposals!