The vibratory slurry sifter, also known as a slurry sifter machine, is used in various industries, including mining, construction, and wastewater treatment, to separate solid particles from a liquid slurry mixture. The equipment typically employs a combination of mechanical and/or chemical processes to separate the solids from the liquid phase.

In the fine chemical industry, sifting starch slurry is a vital process. It is not only the only way to obtain high-quality starch but also involves many aspects such as production efficiency and product safety. Next, we will share the process of slurry sifter equipment.

What is a starch slurry?

Sifting starch slurry is to separate impurities and starch with uneven particle sizes in the starch slurry. In this process, professional screening equipment, such as industrial sifter machine, and ultrasonic vibrating sieve, etc., are required to ensure the purity and particle size uniformity of starch.

Starch Slurry Processing

The first step in sifting starch slurry is pretreatment. Before the starch slurry enters the vibratory slurry sifter machine, it needs to undergo preliminary stirring and dilution to better carry out subsequent screening operations. At the same time, controlling the pH value and temperature of the starch slurry is also a link that cannot be ignored in the pretreatment process.

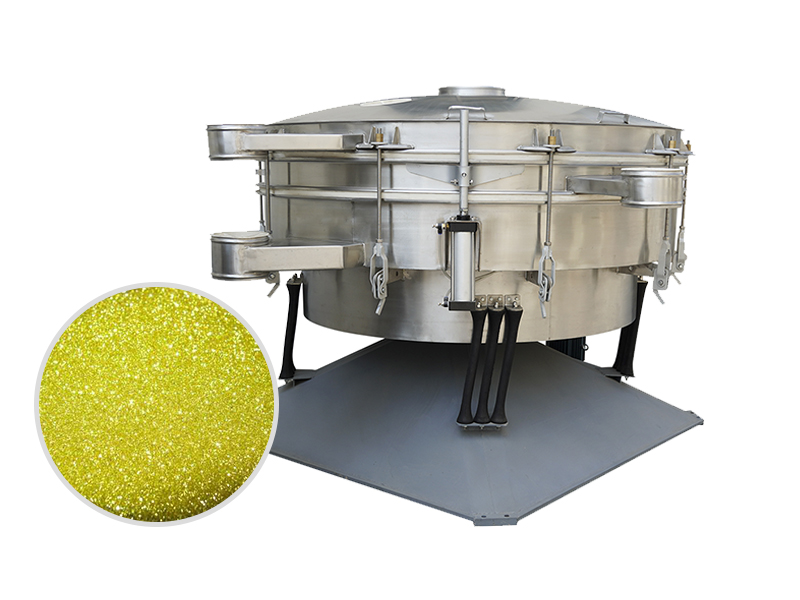

Starch Slurry Sifter Equipment

Next, the starch slurry will enter the slurry sifter equipment for screening. The vibratory slurry sifter machine uses the power of high-speed rotation to separate impurities and larger starch particles in the starch slurry. The mesh size of the sieve (that is, the density of the sieve holes) determines the particle size of the starch after sieving. By adjusting the mesh size of the screen, starch products of different particle sizes can be obtained to meet the needs of different fields.

During the screening process, attention needs to be paid to the fluidity and stability of the starch slurry. Starch slurry with poor fluidity can easily block the screen and affect the screening effect, while starch slurry with poor stability is prone to stratification, precipitation, and other phenomena, resulting in uneven screening. Therefore, appropriate slurry sifter equipment should be selected according to the characteristics of starch slurry.

Things To Note When Screening Starch Slurry

Although the process of screening starch slurry seems simple, it contains a wealth of chemical and physical knowledge. For example, factors such as the speed and time of the slurry screener equipment, the mesh size of the screen, the pH value, and the temperature of the starch slurry, will all have an important impact on the screening effect.

In addition, the efficiency and quality of sifting starch slurry are closely related to the maintenance and management of slurry sifter equipment. Regular cleaning, inspection, and maintenance of the vibratory slurry sifter can ensure its normal operation and extend its service life.