The conical twin screw mixer, also called a vertical cone mixer, is an efficient material mixing equipment. It has excellent mixing performance and can effectively handle a variety of materials. It is particularly suitable for mixing powders with powders, particles with powders, and powders with a small amount of liquid. It is widely used in chemical, dye, pigment, pesticide, veterinary drugs, medicine, plastic, and additive industries. According to different process requirements, the equipment can be customized according to different requirements, such as heating, cooling, positive pressure, vacuum, and other functions.

- Batch workload: 0.1-15cbm

- Mixing time: 15-60 minutes

- Material: 316L, 304, low carbon steel.

Price: US $2,949 -$ 3,800 / Set

Conical Twin Screw Mixer working Principle

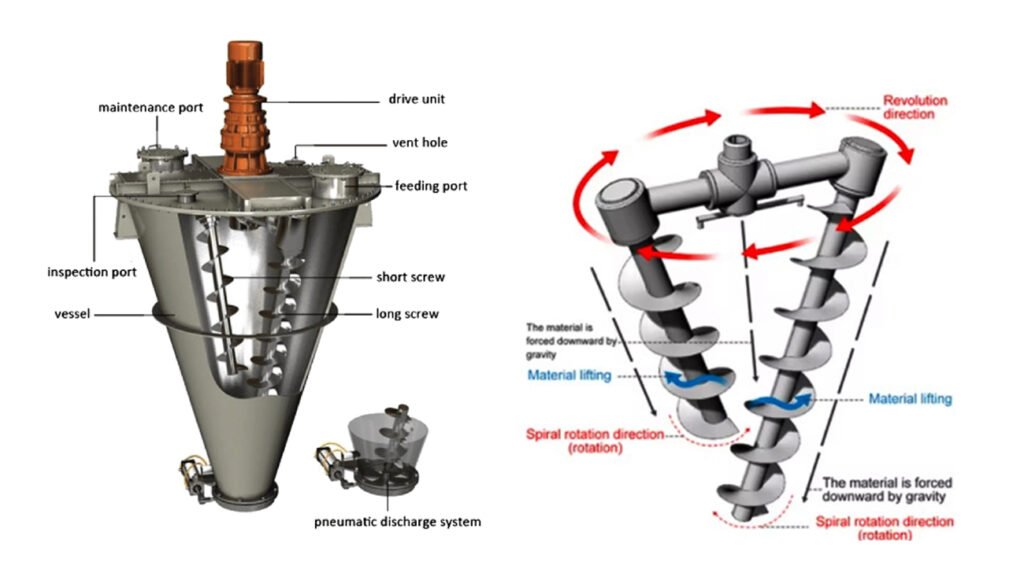

Through the rotation of the two asymmetric spirals, the cone hybrid machine continuously improves the material and matches the slow rotation of the turning arm to form complex material movements. The material on the outer side of the spiral enters the thread through different paths, so that the material continues to be updated and diffused in the direction of the full circle. The material that is raised to the top and then gathered to the center of the center to form a downward -flowing material flow, which effectively fills the gap at the bottom, and finally achieves triple hybrid effects, including the distribution of flow, circulation and material.

Conical Screw Mixer Structures

- The main components of the double-helix conical mixer are composed of key components such as the drive unit system, two inclined screws, rotating arms, barrels, and discharge valves.

- Drive unit system: provides power to drive the screw to rotate.

- Two inclined screws: Through different motion modes, the materials are constantly turned and moved during the mixing process to achieve uniform mixing.

- Rotating arms, center rods and spirals: The spiral is composed of a screw and spiral blades, and it is the direct working part of the mixed material. Barrel: As a material container, it allows the material to be efficiently mixed in a closed environment.

- Discharge valve: After the mixing is completed, the materials are discharged efficiently, and are often equipped with an adjustment device to ensure smooth discharge.

Details

Pressure-resistant barrel cover

Barrel

Screws

Electric motor

Feed gate

Feed inlet

Discharge Inlet

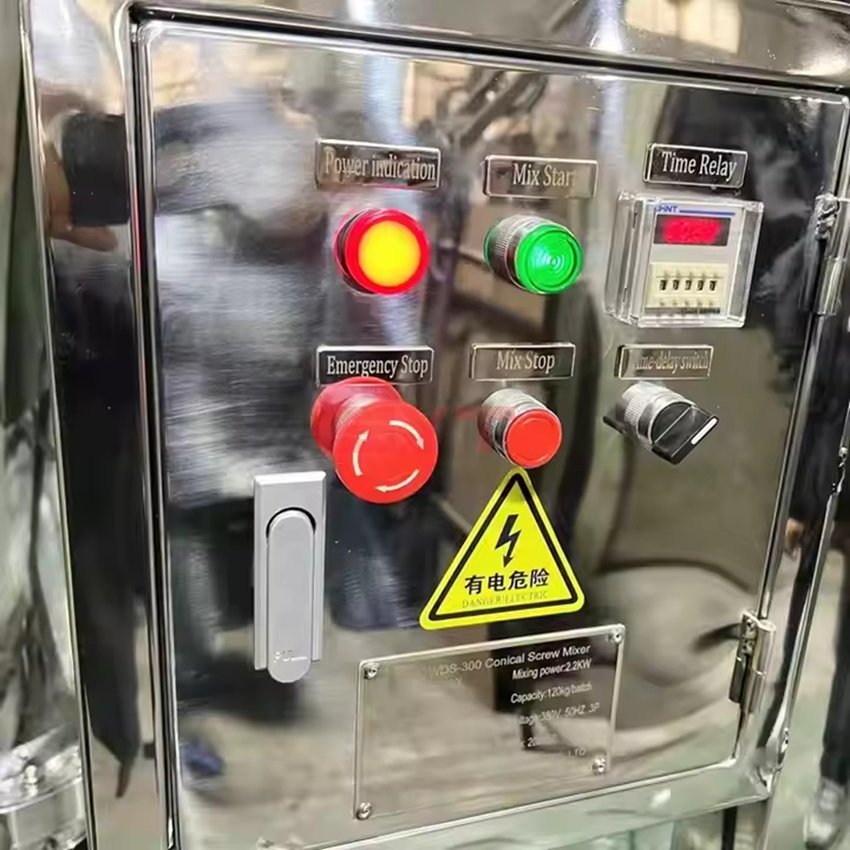

Control panel

Specifications

| Model /Data | Product Capacity(kg/h) | Material granularity(mesh) | Power(kw) | Mixing time(min) |

|---|---|---|---|---|

| SYCM-200 | 95 | 20-250 | 2.2 | 6-10 |

| SYCM-500 | 200 | 20-250 | 2.2 | 6-10 |

| SYCM-1000 | 450 | 20-250 | 4 | 8-10 |

| SYCM-2000 | 900 | 20-250 | 5.5 | 8-10 |

| SYCM-4000 | 1800 | 20-250 | 11 | 8-10 |

| SYCM-8000 | 3600 | 20-250 | 18.5 | 8-10 |

| SYCM-10000 | 4000 | 20-250 | 18.5 | 8-10 |

| SYCM-15000 | 6000 | 20-250 | 22 | 8-10 |

* Can be customized according to special needs.

Customize Conical Mixer Machine Options

Mixing Configuration

The standard conical spiral mixer is usually equipped with two stirring spirals. According to the specifications and requirements of the equipment, you can choose a single (long spiral), double (asymmetric configuration of long and short spirals), or three (two short and one long spiral arranged symmetrically) spiral configuration. Generally, the more spirals there are, the better the mixing effect.

Single Conical Mixer Machine

Single Conical Mixer Machine Double Conical Mixer Machine

Double Conical Mixer Machine

Material Options

The material of the conical screw mixer can be carbon steel, manganese steel, or stainless steel (SS304, 316L, 321, etc.) according to demand. The part of raw material contacting with other parts can be made of different materials. The surface of stainless steel can be finished by sandblasting, brushing, polishing or mirror polishing, etc.

Stainless steel conical screw mixer

Stainless steel conical screw mixer Carbon steel conicalscrew mixer

Carbon steel conicalscrew mixer

Pressure-resistant barrel cover

The barrel cover can be designed as a head type, and the structure is thickened to withstand positive and negative pressures. It also helps to reduce material residue and simplify the cleaning process, especially for those applications that require the barrel to withstand high pressure.

Pressure-resistant barrel cover

Pressure-resistant barrel cover Pressure-resistant barrel cover

Pressure-resistant barrel cover

Feeding method

Feeding can be done manually, by vacuum feeding or by conveying system as required. For some specific applications, the mixing barrel can be designed as a negative pressure environment, allowing dry materials with good fluidity to be sucked into the mixing chamber through a hose, thereby reducing residue and avoiding contamination during the feeding process.

Pneumatic Vacuum Feeder Machine

Pneumatic Vacuum Feeder Machine Pneumatic Vacuum Feeder with hose

Pneumatic Vacuum Feeder with hose

Driving system

The drive unit and power of the mixer can be customized according to the material characteristics, starting mode, and process requirements. The double screw conical mixer is usually equipped with a special double output reducer (composed of wind wheel, gear, and worm gear) to provide smooth and efficient power transmission.

Electric motor

Electric motor Pressure-resistant barrel cover

Pressure-resistant barrel cover

Unloading System

Double cone mixer can choose a ball valve or plum misalignment valve as the unloading device. Spherical valves have better sealing and are suitable for powders, liquids, and negative-pressure environments. Plum stagger valves are easy to operate, control the discharge rate, and minimize the mixing dead zone.

Ball valve

Ball valve Plum misalignment valve

Plum misalignment valve

Additional Features

For precise temperature control, the Double Screw Conical Mixer can be equipped with jacketed circulating media to meet the demand for temperature control. The parts of the mixing cylinder that come into contact with the material can be sprayed with anti-corrosion, anti-caking, or metal barrier materials as required, especially for corrosive or highly abrasive environments. For processes requiring small amounts of liquid addition, the equipment can be equipped with spraying or atomizing devices for uniform distribution and mixing of liquids.

Product Show

Application

Applied in food, pharmaceuticals, chemicals, pesticides, dyes, plastics, minerals, metallurgy, building materials, cosmetics, pigments, coatings, environmental recycling and other industries. Suitable for mixing, reacting, drying and cooling powders (solid-liquid) and powders (solid-liquid). Such as spices, wet powder, coating, granulation, etc.

Corn Starch

Cereal Grains

Coffee Beans

Spice powder

Medicine Powder

Powder coating

Tungsten Metal Powder-

Liquid

Features

- Efficient and fast mixing: Compared with a single-screw mixer, the mixing time is shorter and the efficiency is increased by 2 to 3 times.

- Large mixing capacity: large mixing capacity, high precision, low energy consumption, and the loading coefficient is increased by 25% to 40% compared with a V-type mixer.

- The bottom discharge is fast: the bottom discharge is clean and fast, and the bottom can be tightly closed to avoid leakage.

- Small mixing dead angle: The optimized design minimizes the mixing dead angle of the material and improves the mixing uniformity.

- Easy to clean and replace materials: The equipment is easy to clean and convenient to switch between different mixed materials.

- Reduce maintenance work: The bottom bearing does not require frequent maintenance, reducing equipment maintenance costs.

- Adapt to the batch requirements of large production lines: such as premixed powder production lines, pharmaceutical production lines, etc.

Customer Site

Conical Twin Screw Mixer Supplier and Manufacturer

Sanyuantang is a leading supplier and manufacturer of conical twin-screw mixers. We have been focusing on providing integrated screening, conveying and mixing solutions for 30 years. The conical twin-screw mixer is an efficient and uniform mixing equipment specially developed by our technical team. It is widely used in the pharmaceutical, food, chemical and powder processing industries. Sanyuantang has advanced technology, rich experience in production line customization, and a complete after-sales service system. It is your ideal partner.

FAQS

Related Equipment of Production Line

In addition to the double cone mixer, if you need other types of processing equipment, Sanyuantang Machinery can also provide reliable solutions, such as: