V-type powder mixer, also known as a V blender machine, is a mixing equipment designed for efficient mixing of dry powder, granules, and other bulk materials. Its unique V-shaped mixing barrel structure can achieve uniform mixing and effectively reduce the risk of material separation. The equipment has high mixing efficiency and no dead angle. The barrel body is made of high-quality stainless steel, the inner and outer walls are finely polished, the appearance is beautiful, the mixing effect is good, and it meets GMP standards. V-type powder mixers are widely used in pharmaceutical, chemical, cosmetic, food processing, plastic and other industries.

- Model: V 0.18-4

- Total volume: 180~4000 (m³)

- Materials: SUS304, SUS304L, SUS316, SUS316L

- Application: suitable for mixing materials such as powder and powder, powder and liquid, powder, and small particles, especially suitable for occasions that require fine proportioning.

Price: US $1,650 -$ 2,500 / Set

How does a v mixer work?

The V-type powder mixer works by rotating two cylindrical containers arranged in a “V” shape. As the containers rotate, the materials inside are continuously mixed by the combined forces of tumbling and cascading, resulting in a thorough and uniform blend of powders or granular materials. The V-shaped design facilitates efficient movement and distribution of materials, minimizing segregation and achieving uniform mixing. The machine is widely used in industries such as pharmaceuticals, chemicals and food processing where precise mixing of powders is required.

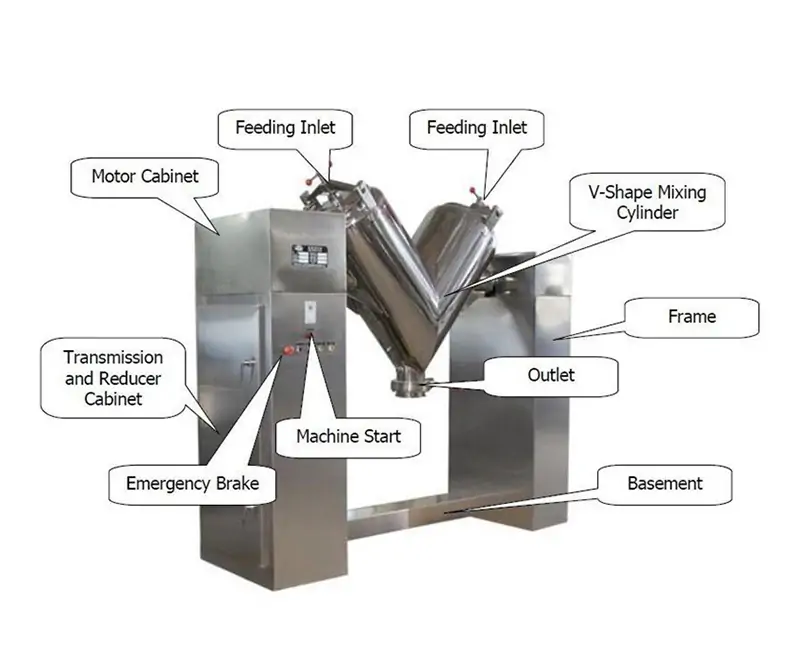

V Type Vertical Powder Mixing Machine Structures

The V-type mixer is composed of a V-shaped barrel, a closed bracket and a transmission device. The discharge port is equipped with a sealed butterfly valve. It operates in a sealed state. There is no dust in the mixing. The materials are generated by two barrels of different lengths during the rotation process. Different drops make the materials cross-mixed with each other, and the mixing uniformity can reach more than 99%. The barrel is made of 304-2B stainless steel, and the inner and outer walls are polished. The machine is equipped with two feeding ports and a timing control device, which is easy to operate. When discharging, you can start the inching button to align the discharge port with the barrel, making the discharge smoother.

V-shaped Mixing Mixing Cylinder

The asymmetry of the V-shaped container makes the powder sometimes gather and sometimes disperse in the rotating container, and the mixing is more uniform.

Drive Motor and Gearbox

The drive motor provides the necessary rotational power for the mixing chamber. The motor is connected to the gearbox, which controls the speed and direction of rotation, allowing for adjustable mixing speeds to accommodate various materials.

Rotating Shaft

The rotating shaft is attached to the V-shaped mixing chamber and facilitates its rotation. As the shaft turns, the two cylinders can tumble and mix the powders or granular materials inside.

Discharge Port

The discharge port is located at the lower end of the V-shaped chamber. After the materials are mixed to the desired level of uniformity, they can be easily discharged through this opening. The port may be equipped with a valve or other mechanisms to control the discharge flow.

Supporting Frame

The supporting frame is the machine’s structural base that holds all other components in place. It provides stability during operation and supports the rotating mixing chamber and motor assembly.

Feeding Inlet

The feeding inlet is the opening through which materials are added into the mixing chamber. Depending on the design, this can be positioned at the top or side of the machine, making it convenient for continuous feeding.

Mixing Blades or Baffles (Optional)

Some V-type mixers may include internal mixing blades or baffles, which further enhance the movement and mixing efficiency of the materials. These blades are typically mounted inside the mixing chamber to help break up clumps and distribute the materials evenly.

Control Panel

The control panel allows operators to adjust the machine’s speed, operation time, and other settings. It typically includes buttons, dials, and indicators for easy operation and monitoring.

Seals and Bearings

Seals are used to prevent powder leakage, while bearings support the rotating shaft and ensure smooth, frictionless operation.

Details

V-Shaped Mixing Clylinder

Feed Inlet

Feed Outlet

Feed Outlet

Operation Panel

Specification

| Model | V-0.18 | V-0.3 | V-0.5 | V-1 | V-1.5 | V-2 | V-2.5 | V-3 | V-4 |

|---|---|---|---|---|---|---|---|---|---|

| Capacity (kg/time) | 72 | 120 | 200 | 400 | 600 | 800 | 1000 | 1200 | 1600 |

| Feeding time (min) | 3-5 | 3-5 | 4-6 | 6-9 | 6-10 | 8-13 | 8-15 | 8-12 | 10-15 |

| Mixing time (min) | 4-8 | 6-10 | 6-10 | 6-10 | 6-10 | 6-10 | 6-10 | 8-12 | 8-12 |

| Total volume (m³) | 180 | 300 | 500 | 1000 | 1500 | 2000 | 2500 | 3000 | 4000 |

| Mixing speed (rpm) | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 10 | 10 |

| Powder (Kw) | 1.1 | 1.1 | 2.2 | 4 | 4 | 5 | 7.5 | 7.5 | 11 |

| Rotation height (mm) | 1580 | 1760 | 2400 | 2840 | 3010 | 3240 | 3680 | 3700 | 4350 |

| Weight (Kg) | 280 | 320 | 550 | 950 | 1020 | 1600 | 2040 | 2300 | 2800 |

Features

- High mixing uniformity: The V-shaped mixer is composed of two asymmetric barrels, which can achieve vertical and horizontal flow, high mixing efficiency, no dead angle, and mixing uniformity of more than 99%.

- No residue and no cross contamination: The contact area between the inside of the barrel and the discharge port is designed to have no dead angle, the mixing process is smooth and stable, there is no isolation phenomenon, and the material is completely emptied to avoid residue and cross contamination.

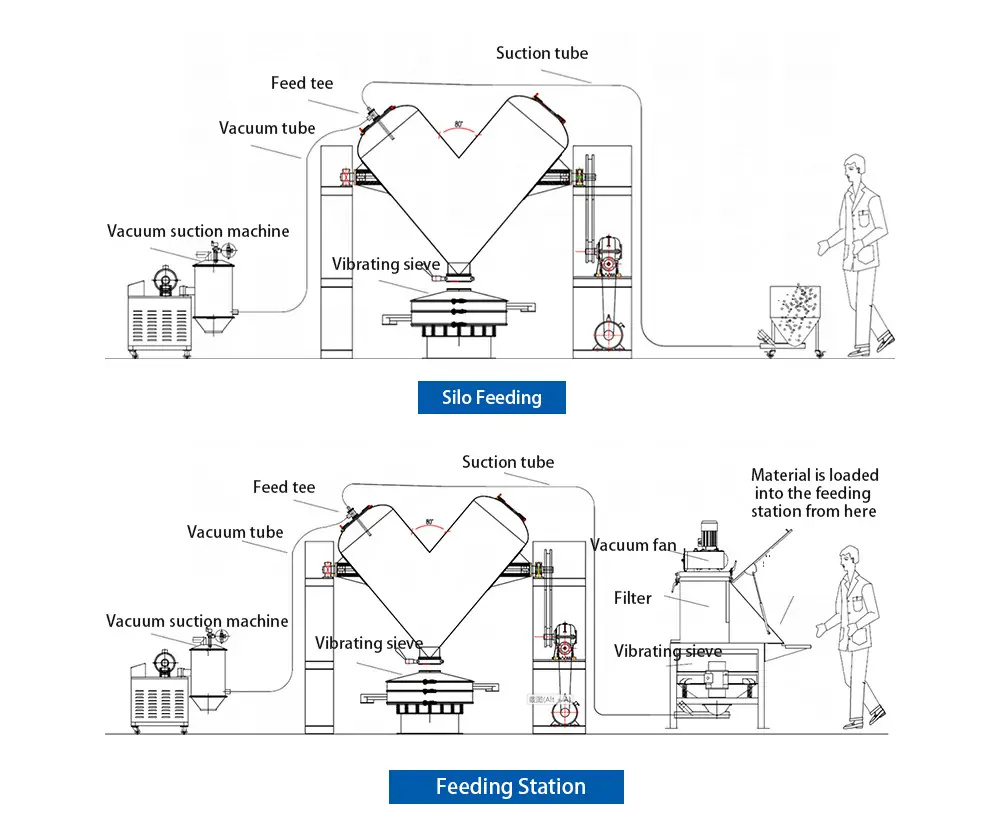

- Efficient feeding and dust-free discharge: Manual feeding or vacuum valve suction device can be selected, and the butterfly valve device is used for discharge, dust-free operation, ensuring a clean environment.

- High-quality materials and clean design: The barrel is made of high-quality stainless steel plate, and the inner and outer walls are polished, with beautiful appearance, not easy to accumulate materials, easy to clean, and in line with GMP hygiene standards.

- Simple operation: The V-type mixer is easy to operate and can be equipped with timing control or point operation to meet different work requirements.

- Customized mixing solution: According to customer needs, a forced agitator can be added, which is suitable for mixing fine powder particles or block materials containing water.

Application

V-type mixer is a highly efficient mixing equipment, which is widely used in pharmaceutical, chemical, food, plastic, cosmetics, ceramic, feed, fertilizer, fuel, ore, and other industries. The unique structural design of V-type mixer makes the materials fully subjected to uniform shear force and friction during the mixing process, so as to achieve efficient and uniform mixing of materials in a short time. Its main function is to evenly mix dry powder or granular materials with good fluidity, especially suitable for mixing materials requiring high uniformity and high precision.

Cereal Grains

Cereal Grains Spice powder

Spice powder Walnut powder

Walnut powder Coffee Beans

Coffee Beans Medicine Powder

Medicine Powder Powder coating

Powder coating Fertilizer

Fertilizer Masterbatch

Masterbatch Liquid

Liquid

- Pharmaceutical industry: V-type mixer is suitable for mixing capsule particles, Chinese herbal condiments, powdered or granular Chinese herbal medicine, etc.

- Food industry: It can be used for mixing condiments, additives, vitamins, sugar products, and other foods.

- Cosmetic industry: A V-type mixer is widely used in the mixing of cosmetic raw materials, such as the production process of creams, lotions, shampoos, conditioners, facial masks, lipsticks, foundations, and other products. It can effectively mix various powders, liquids, and viscous substances.

- Feed industry: It is suitable for mixing various feeds, including fish feed, poultry feed, wild animal feed, bird feed, etc.

- Fuel industry: can be used to mix various fuel raw materials, such as fireworks raw materials, firecrackers, etc.

- Mineral industry: suitable for mixing various powdered or granular ore materials.

Customer Site

Pharmaceutical Powder Mixer

Pharmaceutical Powder Mixer Commercial Powder Mixer

Commercial Powder Mixer Commercial Powder Mixer

Commercial Powder Mixer

V Type Powder Mixer manufacturer

Sanyuantang is a professional V-type powder mixer manufacturer and manufacturer with more than 30 years of industry experience. We are committed to providing customers with efficient and stable overall screening, conveying and mixing solutions. We have advanced production equipment, professional technical team, and strict quality management system to ensure that every link from design, production to delivery of products meets international standards and provides durable and high-quality equipment.

We can customize personalized V-type mixing solutions according to your special needs to help you improve production efficiency, optimize operating processes, and reduce equipment maintenance costs. Choose Sanyuantang, you will get professional, reliable equipment and full-range technical support. We are your trusted partner.