The bulk bag dump station also called a tipping station, which is a hopper and vibratory screener that integrates feeding and screening functions. It is suitable for manually unpacking 0~50 kg of bagged or barreled powder materials. The equipment is equipped with a dust control device, and there is no dust leakage during the unpacking process, effectively avoiding dust during feeding and ensuring a clean operating environment. The stainless steel bag dump station is widely used in the material feeding process of pharmaceutical, food, chemical, and other industries.

- Model SYT-800, SYT-1000

- Discharge weight: 10~50kg/bag

- Discharge speed: 80~160bags/h

- Filter area: 9m²

- Filter accuracy: 2um

- Air consumption: 0.5m³

Price: $1790 – 2430.0 / Set

Working Principle

When handling small bags of materials, they need to be unpacked and introduced into subsequent processes. The operator only needs to manually remove the material bag and then pour the material directly into the bag dump station. When feeding, the dust collection system of the feeding station automatically starts, and the dust collection fan strongly absorbs the fine dust generated by the dumped material.

Then the material enters the vibratory screener, and the vibrating motor drives high-frequency vibration to promote the uniform distribution and rapid flow of the material, and intercept large impurities or particles that do not meet the specifications in the material, so as to ensure that the compliant particles are discharged to the next process in an orderly manner, ensuring production continuity and product quality.

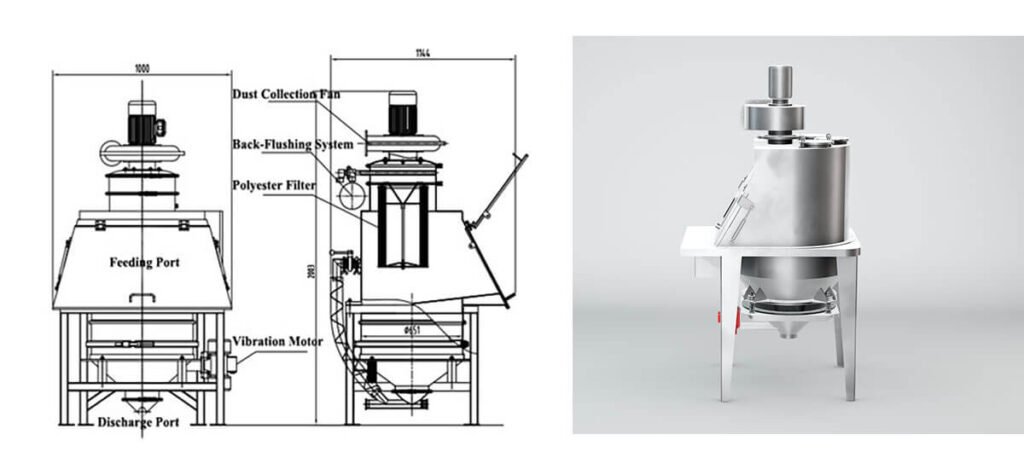

System Structure

The small bag dump system consists of a manual unloading bin, a pressure-proof feeding platform, a feeding bin, a rotary vibrating screen (or inline vibratory screener), a filtration system, a dust collection system, a back-blowing airbag, and a vibration motor.

Structural Features

Manual Unloading Bin:

- Function: As the initial point for materials to enter the feeding station, materials are poured into this bin manually or mechanically.

- Features: Designed with easy-to-operate openings and sealing devices to reduce the leakage of materials during the unloading process.

Anti-Pressure Feeding Platform:

- Function: Support and stabilize the manual unloading bin, and have a certain pressure resistance to ensure safety during the feeding process.

- Features: Strong structure, flat surface, easy to clean, prevents materials from accumulating on the platform and causing pressure.

Under-Feeding Bin:

- Function: Receive materials falling from the manual unloading bin and guide them to the vibrating screen for screening.

- Features: Designed with reasonable flow channels to ensure smooth flow of materials,and reduce blockage and residue.

Vibrating Screen:

- Function: Screen materials and separate particles of different particle sizes.

- Features: Equipped with a vibration motor to generate high-frequency vibration and improve screening efficiency; the screen can be replaced as needed to meet the screening requirements of different materials.

Filter System:

- Function: Capture and filter the dust generated during the screening process to prevent it from entering the working environment.

- Features: Use high-efficiency filter materials to ensure filtering effect; designed with a structure that is easy to clean and maintain to extend service life.

Dust Collection System:

- Function: Collect dust captured by the filtration system and conduct centralized treatment or discharge.

- Features: Closely connected with the filtration system to ensure that dust does not leak; equipped with back-blowing airbags and other devices to regularly clean the dust accumulated on the filter material.

Back-blowing Airbag:

- Function: Provide back-blowing airflow for the filtration system to remove dust on the filter material and restore its filtration performance.

- Features: Automatic control and easy operation; significant back-blowing effect and reduced labor maintenance costs.

Vibration Motor:

- Function: Provide power for the vibrating screen to drive it for high-frequency vibration screening.

- Features: High efficiency and energy saving, stable operation; the vibration frequency and amplitude can be adjusted as needed to meet the screening needs of different materials.

Bulk Bag Dump Station Details

Product Paramenters

| Model | Speed(rpm) | Air pressure(Pa) | Airflow(m³/h) | Sieving area(m³) |

|---|---|---|---|---|

| SYT-800 | 1460 | 1217-1641 | 1550-997 | 0.42 |

| SYT-1000 | 1460 | 0.64 |

Features

- Bag dump dust collection technology: Adopt closed bag opening and negative pressure feeding, no dust overflow, create a dust-free green working environment.

- Anti-blocking system: Optional screening and vibraory screener devices can effectively prevent the entry of large bagged materials and foreign matter, and reduce blockage.

- High-efficiency filtration: High-efficiency filtration capacity greatly reduces material waste and improves production efficiency.

- Environmentally friendly large air volume dust collection: built-in high-efficiency dust collector, large air volume dust collection, easy maintenance, can be connected with central dust collection.

Advantages

- Simple and safe structure: simple structural design, safe and reliable feeding process, easy to operate and maintain.

- Automatic dust removal function: built-in back-blowing dust removal device, automatic dust cleaning, reducing manual maintenance costs.

- Maintenance-free and long life: maintenance-free, jet-type self-cleaning filter element, no need to change frequently, high-quality fan, long service life.

- Customized design: automatic cutter, waste bag recycling, vibrating screen, etc. can be configured to meet the personalized needs of users and improve the automation and environmental protection level of the overall equipment.

- Main material selection: A variety of main materials can be selected according to the actual needs of users: SUS304, SUS304L, SUS316, SUS316L, carbon steel, etc.

Application

The bag dumping station is suitable for unpacking, feeding, screening, and unloading small bags of materials in the pharmaceutical, chemical, and food industries, and is particularly suitable for feeding and screening of materials with poor fluidity.

Case

China Bulk Bag Dump Station Factory

Sanyuantang Machine is a professional supplier and factory of powder bag dumping station in China. We mainly provide powder processing technology services to customers in the food, pharmaceutical, and chemical industries, including processing technology and engineering design, development, and application of various types of powders and solid materials. In addition, we supply powder material processing equipment such as powder bagging stations, and automatic unloading bins, as well as crushing, conveying, screening, mixing, packaging, and other equipment! Contact us for details and quotes on bag dump stations.