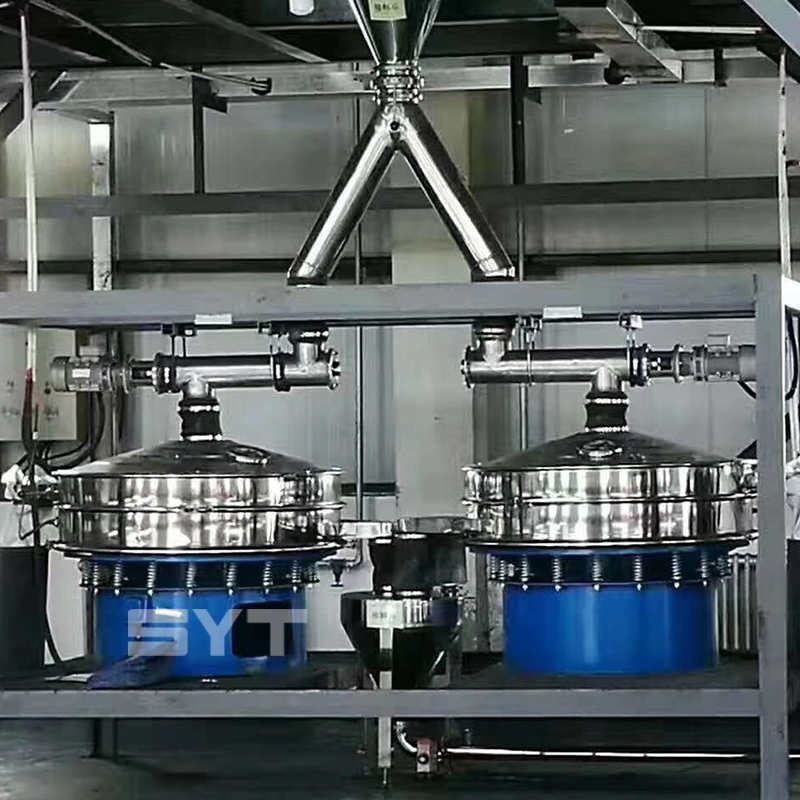

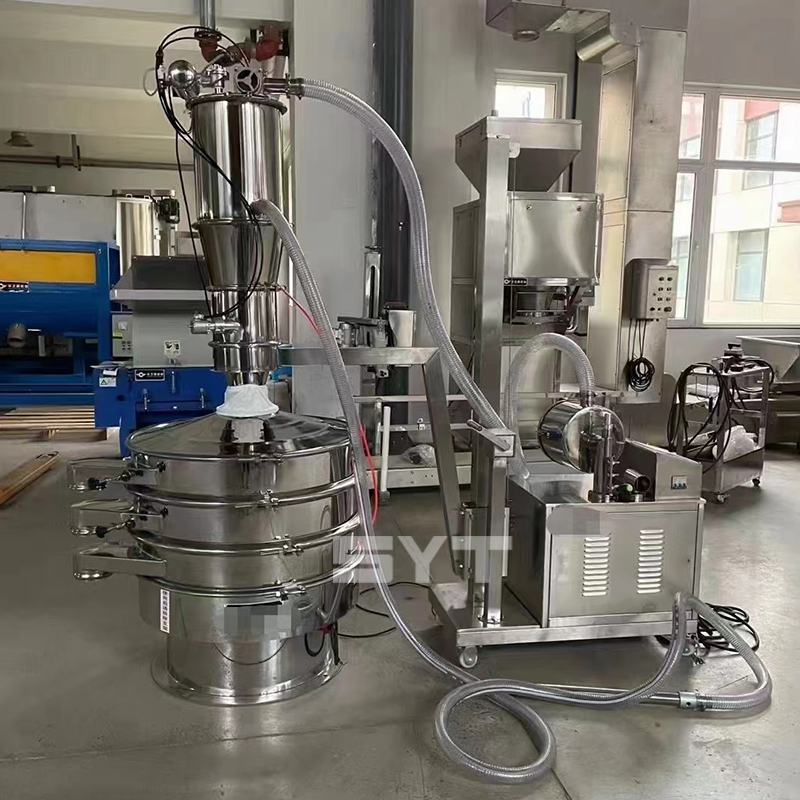

Metal powder sieving machine is a device used to screen metal powders of different particle sizes. These machines typically use a vibrating or gyratory motion to pass the metal powder through a sieve or screen, allowing the fine particles to pass through while retaining the larger ones. They are commonly used in industries such as metallurgy, chemical engineering, and powder metallurgy. The following are several commonly used types of metal powder screening and conveying machine.

Features

- Fully sealed design to prevent chemical materials from flying powder and leakage.

- Using an explosion-proof motor, higher safety.

- Made of 304 stainless steel, corrosion-resistant, and resistant to strong acids and alkalis.

- High screening accuracy, suitable for screening powdery materials and granules of 1-500 mesh.

- Continuous automated production, 1-5 levels of grading screening.

- Small size, easy to move, and highly adaptable to the production line.

- Easy to replace the screen, it can be replaced in 5-10 minutes.

- Long service life, saving equipment maintenance costs.

Application

Electromagnetic materials, metallurgical powder, metal powder, welding rod powder, iron powder, zinc oxide, alumina powder, alloy powder, molybdenum powder, cobalt powder, steel sand, copper powder, nickel powder, silicon powder, silver powder, titanium oxide, tungsten carbide, tungsten powder, titanium powder, stainless steel powder, etc.