3D Metal Powder Screening is an important part of metal 3D printing technology. The quality control of metal powder affects the accuracy, strength, and durability of the final printed parts. The following is a detailed discussion of 3D printing metal powder screening:

The significance of 3D metal powder screening

- Improve powder quality: remove impurities and uneven particles in metal powder to improve the purity and uniformity of powder.

- Optimize printing effect: high-quality metal powder can ensure the accuracy and strength of printed parts and reduce the occurrence of defects such as holes and thermal cracks.

- Reduce costs: effective screening can reduce powder waste, improve material utilization, and thus reduce production costs.

3D metal powder screening equipment selection

When selecting 3D metal powder screening equipment, it is necessary to comprehensively consider screening efficiency and accuracy, safety and environmental protection (such as closed design, explosion-proof and grounding, dust collection), durability and easy maintenance (such as material selection, structural design), customization and adaptability (such as screen adjustability, adaptability to different materials and processes, etc., to meet production needs and improve overall production efficiency. The following are several equipment solutions that our company usually recommends to customers:

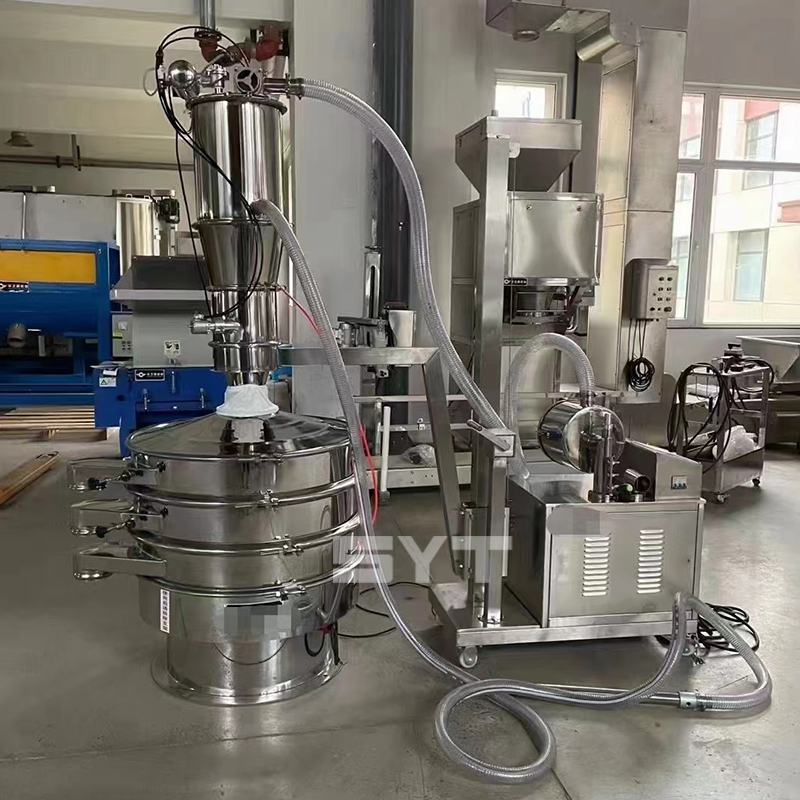

Rotary Vibrating Screen

- Material: 304/316 stainless steel

- Model: SY-800, 3 Layer

- Screen size: 5 -150 mesh

- Output: 500kg-3 tons/hour

- Features: Use mechanical vibration to screen metal powder and separate the particle size of powder. Suitable for processing large amounts of powder, and has high screening efficiency.

ultrasonic Vibrating Screen

- Material: ss304/316

- Model: SY-800, 1 Layer

- Screen size: 150 -625 mesh

- Output: 100 kg- 3 tons/hour

- Features: Using the vibration of ultrasound, the metal powder will produce tiny vibrations on the screen, making it easier to separate through the screen. It is suitable for processing powders that are prone to static electricity, easy to agglomerate, have strong viscosity or are difficult to screen.

Airflow screening machine

- Material: Food grade 304/316 stainless

- Model: WQ50-130

- Screen size: 5 – 500 mesh

- Output: 100Kg-5tons/hour

- Features: use the power of airflow to blow metal powder away and separate it through screens of different particle sizes. Suitable for processing ultrafine powders, and has high screening accuracy.

Videos

Through the above article, you have learned about the relevant knowledge of 3D metal powder screening knowledge and solutions. If you need to purchase high-quality vibrating screens or metal powder production line systems, please contact Sanyuantang Machine. We will provide customized solutions according to your requirements.

Related products

In addition to 3D metal powder screening machine, we also provide a series of accessories and supporting equipment to meet customers’ diverse screening needs, including conveying and feeding equipment, silos, dust removal devices, spare parts.