The Fully Balanced Square Gyratory Vibrating Screen is a newly designed high-efficiency screening solution from Sanyuantang Machinery. Featuring a fully balanced dynamic design, it runs with exceptional stability and minimal vibration impact on the supporting structure. With its adjustable screen inclination angle, it provides optimal adaptability for different materials—from coarse particle separation to fine powder classification.

This machine is ideal for industries that demand precision and reliability, such as chemical, food, building materials, wood processing, and mineral screening.

- Model: SYT-2045

- Screen size: 2.0*4.5 m

- Screening area: 8 m2

- Screen inclination: 0-90°

- Layers: Custom

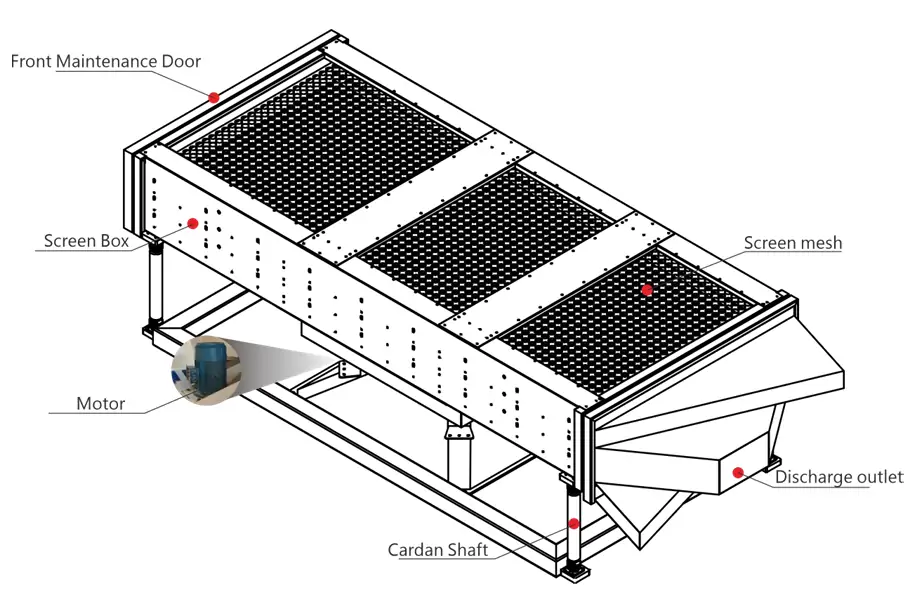

Parts

The following section will elaborate in detail on the core components that constitute the screening system.

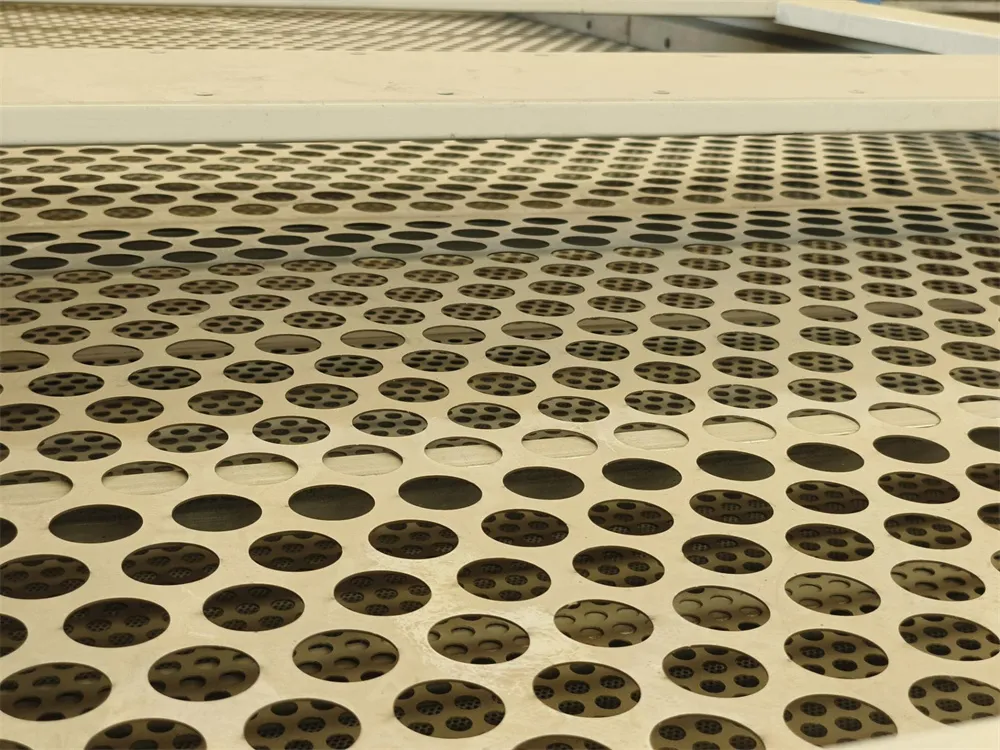

Screen Deck: Positioned inside the screen box, it classifies materials based on particle size. The mesh count (aperture size) can be selected according to specific screening requirements.

Screen Box: The main structural frame that houses the screen deck. It enables the screening of material through vibrational motion.

Cardan Shaft: Provides a flexible linkage between the screen box and the base frame. It ensures stable power transmission while absorbing vibrations to protect the upstream drive system, serving as a critical junction for torque transfer and motion damping.

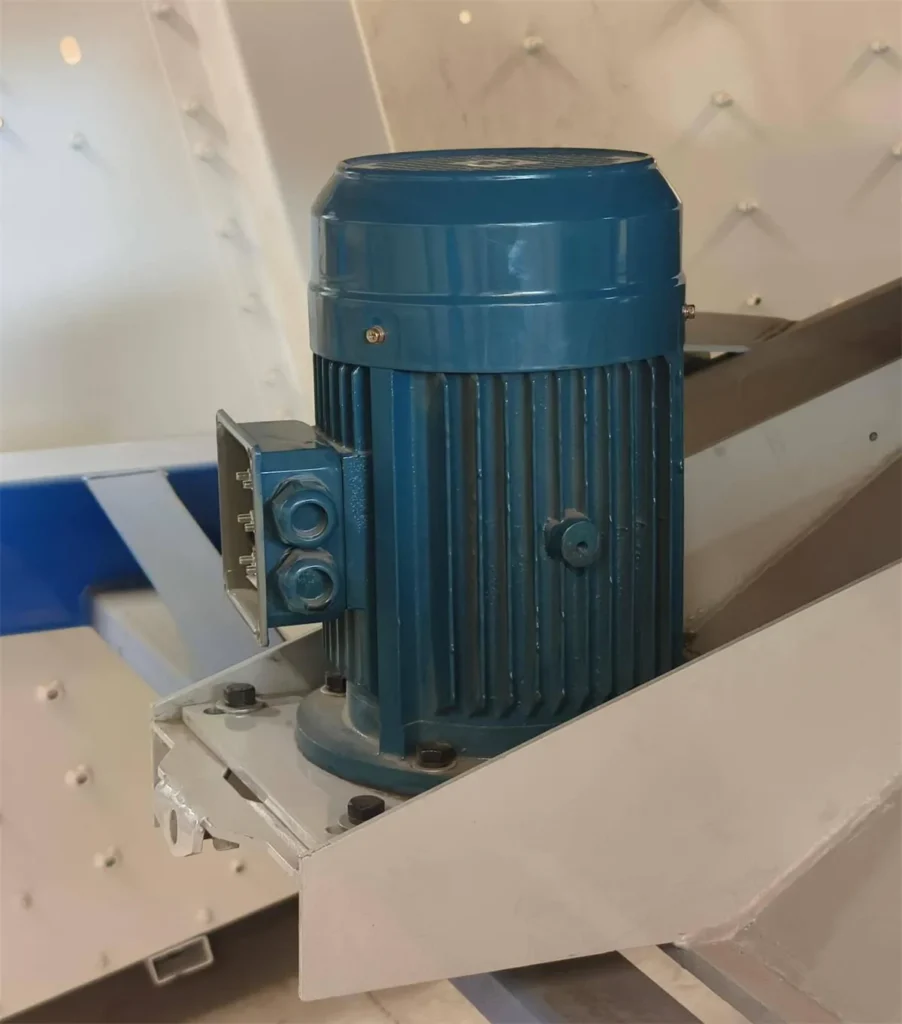

Drive Motor: The primary power source, featuring a fully copper-wound, three-phase asynchronous motor designed for high efficiency and smooth operation.

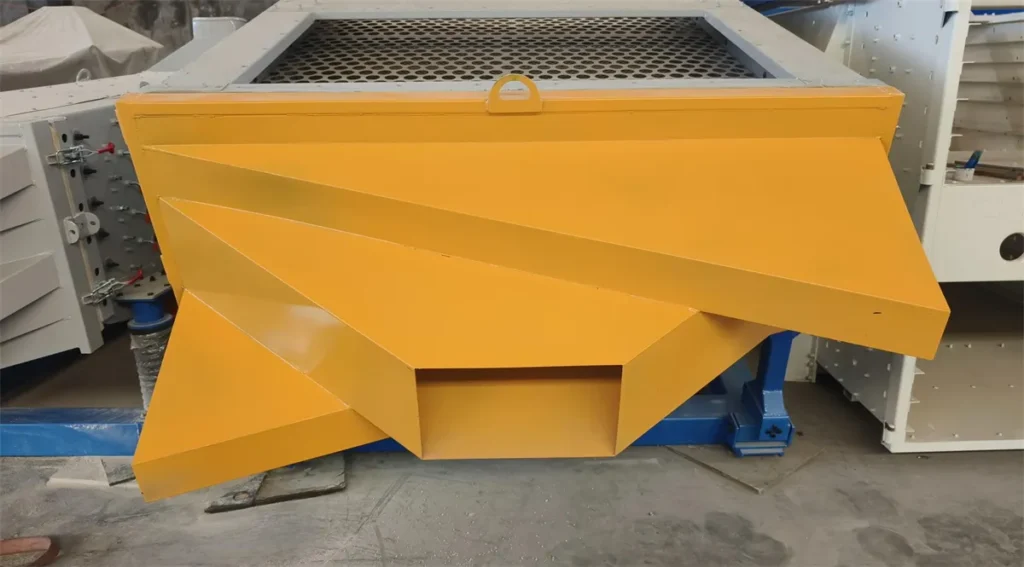

Discharge Chute:The geometry of the chute can be custom-configured to meet specific client requirements and layout specifications.

Working Principle

The Fully Balanced Square Gyratory Vibrating Screen operates on a compound motion drive mechanism. This mechanism generates a uniform gyratory motion that ensures material is evenly dispersed across the entire screening surface.

The high-amplitude gyratory motion continuously redirects the flow of material. This action is key to effectively preventing particle blinding, also known as mesh clogging.

The system is powered by a pair of synchronized motors. These motors drive precision-configured counterweights, which generate the necessary centrifugal force.

A defining feature is its intrinsic self-stabilization. The centrifugal force produced is dynamically balanced by reverse inertial forces, resulting in a stable screening frame with minimal vibration transmission.

Our Fully Balanced Square Tumbler Screen Machine is designed with meticulous attention to detail. Every component is crafted to deliver superior performance, reliability, and long-lasting operation.

Motor

High-performance motor provides stable and efficient power output, ensuring consistent vibration and smooth operation under various working conditions.

Discharge Outlet

Optimized outlet design ensures smooth material flow and prevents clogging. The angled structure enhances discharge efficiency and reduces material residue.

Screen Mesh

Constructed from durable, precision-perforated materials that deliver excellent screening accuracy and extended service life. Available in multiple mesh sizes for customized applications.

Front Maintenance Door

Convenient front access door allows for quick inspection, cleaning, and replacement of internal components, significantly reducing maintenance downtime.

Cardan Shaft

Robust cardan shaft transmits power evenly to the screen body, maintaining balance during operation and minimizing vibration and mechanical wear.

Technical Specifications

| Model | Screen Size (m) | Screening Area | Inclination | Layers | Power | Rotations |

|---|---|---|---|---|---|---|

| SYT2045 | 2.0 × 4.5 | 8 m² | 0°–90° | Customizable | 4 kW | 220 RPM |

Product Show

Features & Advantages

Fully Balanced Dynamic Design

A unique motion balance system neutralizes inertia and vibration, reducing the stress on foundations and structural supports.

Stable performance.

Long service life.

Minimal noise and vibration.

Adjustable Inclination (0°–90°)

The inclination of the screen deck can be freely adjusted to suit the material type.

Boosts screening efficiency by over 30%.

Achieves 95–99.9% separation accuracy.

Prevents mesh clogging and material buildup.

High-Efficiency Gyratory Motion

The synchronized motor and counterweight drive generate smooth compound motion that evenly distributes materials across the surface.

Continuous redirection of materials.

Uniform particle movement.

Excellent anti-blinding capability.

Modular & Customizable Structure

Available with 1–5 deck layers, customizable to meet throughput and accuracy requirements.

Handles 0.5–50 T/H capacity range.

Compact square-frame design.

Easy to assemble, disassemble, and clean.

Energy-Efficient & Durable Construction

Built with premium materials and precision-engineered components.

Fully copper-wound motor for high efficiency.

Rugged structure for 24/7 continuous operation.

Long-lasting wear-resistant screen deck.

Low Foundation Vibration (<0.3g)

Thanks to its fully balanced drive and square base plate, the machine operates steadily—even under full load or vertical installation (90°).

Protects surrounding equipment.

Reduces installation cost.

Ideal for sensitive production environments.

Fully Balanced Square Gyratory Vibrating Screen Videos Show

Application

The Fully Balanced Square Gyratory Vibrating Screen is widely used in building materials, wood processing, and other industries for various granular materials:

- Building materials industry: manufactured sand, natural sand, quartz sand, perlite, dolomite, calcite, feldspar, etc.

- Wood processing industry: wood chips, wood blocks, wood fibre, wood pellets, palm fibre, bamboo shavings, coconut shell fibre, charcoal briquettes, wood shavings, sawdust, etc.

- Other industries: Suitable for screening granular materials with particle sizes ranging from 0.5 to 30 mm, where the bulk density of the material should preferably be less than 0.8.

calcite

calcite perlite

perlite feldspar

feldspar wood chips

wood chips wood pellets

wood pellets charcoal briquettes

charcoal briquettes

Why Choose Sanyuantang Machinery

✅ With over 30 years of manufacturing experience

✅ Professional technical consultation & customization

✅ Cost-effective logistics and delivery solutions

✅ Reliable after-sales tracking service

Customize Your Fully Balanced Square Gyratory Vibrating Screen

To obtain the most suitable screening solution, please provide the following basic parameters:

- Material Information: Name, particle size, moisture content, processing capacity

- Screening Requirements: Number of screening layers, mesh size, target particle size

- Structure and Materials: Frame/screen mesh material, corrosion resistance or wear resistance requirements

- Operating Conditions: Temperature, amplitude, frequency, voltage

- Installation Environment: Indoor/Outdoor, Space Constraints, Support Method

- Special Requirements: Explosion-proof, Automatic Screen Cleaning, Vibration Isolation, etc.